In order to keep up with a changing industry, packaging and containers have been redesigned for easier use. Correct packaging is now indispensable to deliver manufactured products with their original quality (taste and shape) unchanged.

Before the products even reach the market, packaging, transportation, and sales must occur. Thus, it is important for companies to select optimal packages, containers, and labels. In addition, packages must not only improve product protection but also communicate information such as expiration dates and brand logos. Because of this, it is crucial for companies to choose the correct packages, containers, and labels.

Companies must also pay close attention to environmental concerns from the viewpoints of global environment protection and CSR. In addition, they may want to deliver new designs to customers in the form of non- conventional packages.

Keeping these ideals in mind, companies can provide new products for their customers while decreasing production, delivery, and environmental costs.

About Packaging Machines

1.Bottle filling machines

Bottle filling machines fill a specified amount of products such as beverages, foods, and medicines into bottles. According to the production capacity, they are roughly classified into rotary type and line type filling machines.

Based on the measuring type, they are classified as follows:

(1) Regulated liquid level type (mainly for beverages)

(2) Piston type (mainly for viscous products)

(3) Weight type (filling during measurement)

(4) Flow meter type (measuring function-assisted liquid level regulation) In addition to bottles, cans and paper containers are commonly used in bottle filling machines. Also, some machines have recently been designed for filling into bag-in-cartons (or bag-in-boxes) for environmental considerations.

The machine used to fill a particular container depends on the contents. The above machine is for bottle filling.

2.Sack filling machines

Sack filling machines cut and seal sacks into a specified dimension after filling contents like gases, liquids, and powders. Major machines of this type include vertical forming machines, stick packaging machines, and three-side (or four-side) seal packaging machines.

- Vertical forming machines

Vertical forming machines consist of a combination of a cylinder that supplies products and a

former (metallic tool) that forms packaging materials into a cylindrical shape.

Targets include powders, frozen foods, meat/marine products, agricultural products, condiments, sweets, and snacks.

- Stick packaging machines

Stick packaging machines are a kind of vertical forming machines used for individual packaging

of small amounts into slender packages. Stick packaging is widely used for granular powders and viscous liquids such as foods, medicines, and cosmetics.

- Three-side seal packaging machines

Three-side seal packaging machines are one form of small bag packaging. They work by folding

a single sheet in half and sealing the three contacting edges. These machines have an advantage over four-side seal packaging machines by increasing the amount packaged by 20 to 30%.

3.Thermoforming and filling machines

Common thermoforming and filling machines include press through, portion pack, and blister packaging machines.

These machines automatically fill and seal products while forming containers.

- PTP (press through packaging) machines

Produces a form of packages from which contents will be taken out by pressing them from the

container side to break the upper lid. This type of machine is used mainly for a wide range of medical tablets.

- Portion pack packaging machines Produces portions for each person.

They are used for individual packaging of desserts such as puddings or jellies as well as margarine, jams, and syrups.

- Blister packaging machines

Puts products in transparent plastic containers (blister cases) and covers them with mounts.

There are two types of packaging: the seal blister packaging that applies heat for press bonding and the slide blister packaging that bends blister cases and inserts mounts in between.

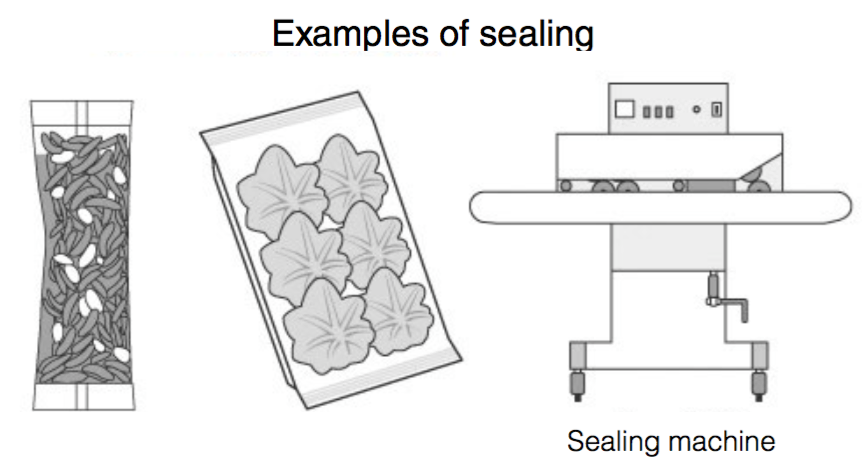

4.Sealing machines

Seals the contents to isolate them from outside air to preserve foods and other products.

These machines are classified as follows:

● Seal type

● Heat seal type

● Impulse seal type

5.Closing machines

Closing machines are also called clippers.

This type of machine produces packages that can be closed again after breaking their seals or taking a part of the contents out. These machines twist the openings of bags to close them with plastic-covered wires. In addition to the wire type, there is also the tape type of clippers.

Puts breads, candies, and other products in bags and seals their opening with metallic/vinyl ties, tapes, etc.

6.Labeling machines

Labeling machines are generally called labelers. Major types of labeling machines include sheet-fed labelers that put labels prepared on separate sheets, roll labelers that cut rolled labels and take them out, and tack labelers that use labels with tacky glue pre-applied to the back side. An increasing number of shrink labeling machines are also used because of their quality finishing.

■ Sheet-fed labelers

Takes labels prepared on separate small sheets out of label magazines and then applies glue to

them to affix them to containers. These labelers are further classified into subcategories according to how to take out labels and apply glue.

■ Roll labelers

Cuts rolled labels using cutters and takes each cut label out to affix them to containers through the gluing process. The configuration for processes following label cutting is almost the same with that of sheet-fed labelers. However, roll labelers can also handle types of labels that sheet-fed labelers cannot, such as film and thermosensitive labels.

■ Tack labelers

Peels labels with tacky glue pre-applied to the back side to affix them to containers. Labels are supplied in a rolled state in which they are affixed onto mounts.

■ Shrink labeling machines (shrink labelers)

Shrink labeling machines (shrink labelers) attach labels to containers of various materials and shapes such as PET bottles. These machines automatically cover part of PET bottles and other containers with printed cylindrical heat shrinking films.

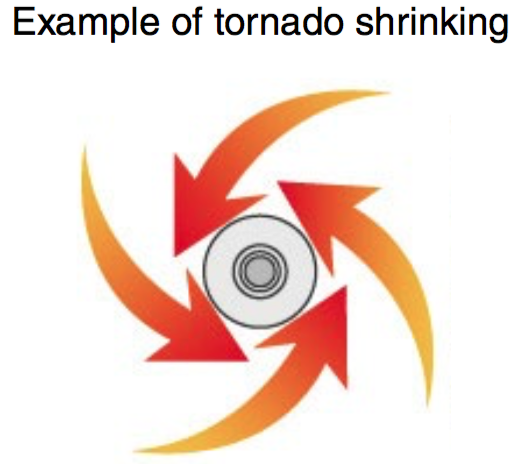

■ Label shrink packaging machines (shrink tunnels)

Label shrink packaging machines make film labels with product names and other information on

them stick to bottle-shaped products by applying heat to them. In general, the steam type of these machines features quality finishing, but it also requires large-scale equipment and removal of water drops after shrinkage. On the other hand, the hot air type has been regarded to have a problem in finishing. The tornado shrink type has entered the market by providing quality finishing without large scale equipment purchases.

7. Cartoning machines

These machines are generally called cartoners. According to the level of processing on these cartons, there are two types of machines: horizontal/vertical cartoning machines and wrap around cartons.

There are several types of cartoners, such as horizontal/ vertical cartoning machines and wrap around cartoners.

8.Wrapping machines

Wrapping machines are largely classified into the fold, twist, stretch, and shrink types.

■ Fold wrapping machines

Fold wrapping machines are classified into the following three types according to target

products:

(1) Those used for small boxes of cigarettes, candies, chocolates, etc. This type can offer symmetric folding lines to achieve beautiful finishing.

(2) Those used for bread, rolled/sponge cakes, and other soft products that easily generate dimension errors.

(3) Those used for individual packaging of products like bread buns and fancy chocolates that fold the entire wrapping, collectively, to the bottom.

■ Twist wrapping machines

Twist wrapping machines have been developed for candies and other small sweets.

■ Shrink type

Can be used for individual packaging (for large quantities as well) by utilizing the cohesion of shrink films during shrinkage.

To simplify packaging, an increasing number of products have been changed from corrugated boxes or paper containers to shrink packages.

■ Stretch type

Used for packaging of fresh foods (vegetables, fruits, meat, and fish) because of the self-tack,transparency, and comfortable feel of stretch films. This packaging is mainly used in supermarkets.

9.Vacuum packaging machines

Vacuum packaging machines package products in a vacuum or low-pressure sealed state using packaging materials having a good gas barrier property. The main purpose is to prevent deterioration of foods and industrial products due to contact with oxygen.

Eliminates oxygen in packages through evacuation or low-pressure sealing to prevent deterioration of products.

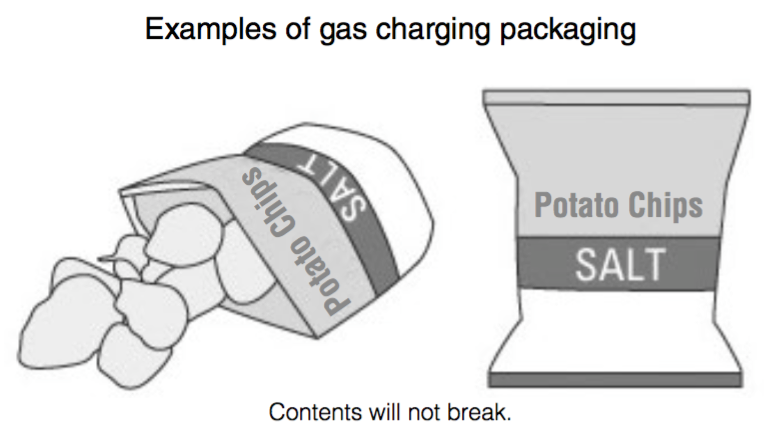

10.Gas charging packaging machines

Gas charging packaging machines charge gases other than air (such as nitrogen gas and carbon dioxide) into packages. Having the same purpose as vacuum packaging machines, these types of machines are ideal for products whose shapes may change and contents which may break or deform under pressure. Target products include potato chips, deli meats, and cheese slices.