- What is a labelling machine?

- Which labelling machines are available?

- How does a labelling machine work?

- For which applications can labellers be used?

- Which products can be labelled with labelling systems?

- Which surfaces can be labelled with labelling machines?

- Can labelling machines be integrated into an existing production line or packaging line?

Labeling Machine FAQ

Labeling systems & labeling machines: Frequently asked questions

Summary of questions:

1. What is a labeling machine?

Labeling machines are used in production lines or packaging lines in all industries. Labelling systems are available in various tree shapes and configurations. A labelling machine applies ready-made labels to a product or product packaging. The product is identified by the application of the labels. Labeling machines can be used to automate the labeling process – this offers considerable time savings in your production. You are spared tedious and time-consuming application of the labels. By using labelling machines, labels can be applied to a product faster and more precisely.

2. Which labeling machines are available?

There are different types of labeling machines depending on the application:

Manual labeler

A manual labeling machine is operated by hand. Small batches can be labelled quickly by using manual labeling devices. This saves set-up time and costs. The labeling device applies the label precisely to the product – you are spared the tedious manual alignment of the label. Manual labeling systems are mobile and therefore flexible in production.

Semi-automatic labeling machine

With semi-automatic labeling machines, the product is placed in the labeling machine by hand. The labeling process is started automatically by hand or foot operation and the label is applied to the product. The product is then removed manually. Medium-sized batches can thus be labeled without difficulty and higher production numbers can also be handled. Semi-automatic labelers take more work off the operator compared to manual operators. If your production quantities vary greatly, a semi-automatic labeler may be the right choice for you.

Fully automatic labeling machine

Automatic labelling systems are permanently integrated into production lines or packaging lines. The labelling process is fully automatic and requires no human intervention. Fully automatic labellers are ideal for high production volumes, as these cannot be handled by hand. Individual solutions are often required for automatic labelling. Due to a modular construction system of the fully automatic standard machines from SBM, individual adjustments can be made quickly and economically. For further requirements SBM offers appropriate special machines for labeling your products.

Label dispenser

Label dispensers apply labels precisely and quickly to products and packaging. Thanks to their compact design, label dispensers can be easily integrated into your production line.

Label print dispenser

Label print dispensers consist of a label dispenser and label printer. The printing and application of labels takes place in one device. By using different applicators, almost any labelling requirement can be met.

3. How does a labeling machine work?

A label roll is inserted into the labeller and threaded according to the threading scheme. Depending on the application and labelling requirements, the labels are pre-printed and only need to be applied to the product or the labels are printed inline. This can be implemented by integrating a printing module – the labels can thus be printed in the machine. Either the label is printed before it is applied to the product or the label is printed with additional information after it is applied to the product.

With manual labelling machines, the label is applied by hand. With fully and semi-automatic labellers, the labelling process is automatic.

Depending on the application, the product can be applied using different methods.

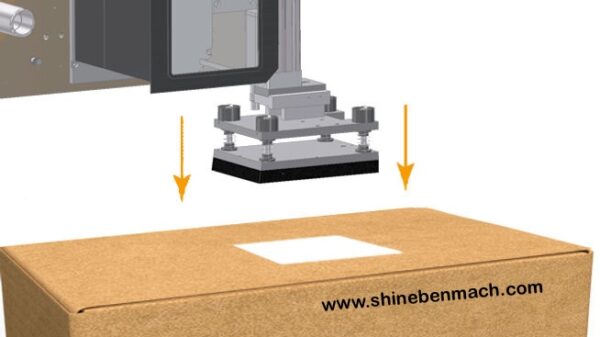

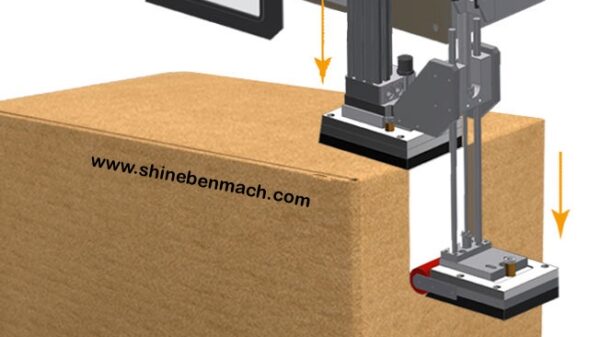

Wipe-on Labeling

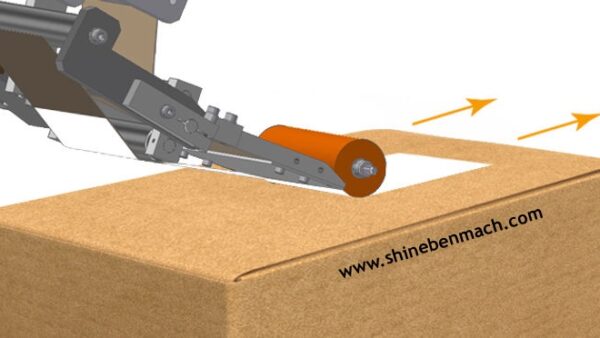

Wrap around labeling

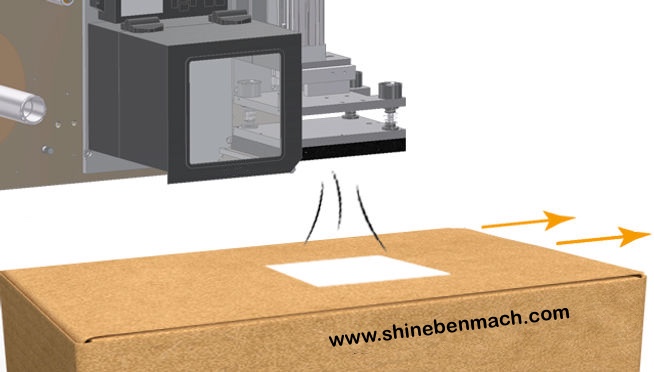

Blow-on Labeling

4. For which applications can labelers be used?

Labeling machines apply ready-made labels to products. There are different technologies depending on the type of labelling, whether cold-glue labelling, hot-glue labelling, wet-glue labelling, self-adhesive labelling and sleeve labelling. The labeling machines from SBM are used for the application of self-adhesive labels.

Labelers can be used for a wide variety of labelling applications:

Side labelling of large containers

All-round labeling of round, horizontal products

All-round labeling of narrow, horizontal products

All-round labeling of syringes

Bottle labeling

Wrap-around labeling of small, cylindrical products

Side labeling of small, cylindrical products

Side labeling of large, cylindrical products

Side labeling of shaped bottles

Form bottle labeling – multi-sided

Top and bottom labeling Side labeling of small, cylindrical products

Top labeling of high products

Top-side labeling of flat products

Top labeling of tubes

Side labeling of rectangular products

Corner labeling of bulk containers

Safety labeling of round, cylindrical products

Tamper-evident labeling Seal labeling of rectangular products

Labeling and printing of flat products

pallet labelling, single-sided, double-sided, multi-sided

5. Which products can be labeled with labeling systems?

A wide variety of products and product packaging can be labeled with labeling machines. Whether large, small, angular, cylindrical, conical or oval product formats – with labeling systems, almost any product shape can be labeled. SBM offers suitable labeling machines for all formats and surfaces.

6. Which surfaces can be labeled with labeling machines?

Basically, almost all product surfaces can be provided with labels with labeling machines:

- oily surfaces

- damp surfaces

- rough or dusty surfaces

- soft or elastic surfaces

- smooth surfaces

- solid surfaces

The right choice of label material and label adhesive is crucial here. At SBM, we would be pleased to advise you on the right choice of labels – tailored to your production environment and conditions.

7. Can labeling machines be integrated into an existing production line or packaging line?

Fully automatic labeling systems can be integrated into production lines and packaging lines. These are usually connected to other systems and machines in the line via a conveyor belt. – Both hardware and software.

Semi-automatic and manual labeling systems can be used flexibly in the production facilities – they are not integrated.