Class is in session!

If you are new to the world of flexible packaging automation, it can feel a bit overwhelming. Don’t worry, we’re here to help.

This article will give you a high-level overview of different machine types, equipment specifications, and will define commonly used industry terms.

Let’s get started with the basics.

Introduction to flexible packaging

According to the Flexible Packaging Association, flexible packaging is any package or any part of a package whose shape can be readily changed. Examples include pouches and bags. Its opposite is rigid packaging, which includes things like bottles, cans, and jars.

Many top companies are adding flexible packaging to their lineup, for reasons including the following:

- Low cost per package

- More surface area for graphics and messaging

- Less risk of breakage and injury if dropped

- Low storage and shipping costs

- Small carbon footprint

- Increased consumer demand for portable, lightweight, flexible packages

Flexible packaging materials

Flexible packaging equipment processes a layered (usually plastic) material called film to produce filled bags, pouches, sticks, and other flexible package types. This material usually contains a sealant layer that bonds together with heat to create a sealed package.

Some flexible packaging machines use a large roll of film wound around a hollow core, called rollstock (pictured at right), to form bag shapes.

Other packaging machines use already-formed bags, usually called premade pouches.

In either case, rollstock and premade bags are purchased from a film supplier, which is a company that creates or converts packaging materials. Sometimes these materials can be purchased directly from an equipment manufacturer, and other times the film supplier is a separate entity. Ask your packaging machine manufacturer for their recommendations for film suppliers.

Types of automatic flexible packaging machines

FORM FILL SEAL

Form fill seal machines are the most widely-used automatic flexible packaging machine type. This equipment does exactly what its name suggests: Forms bags, fills them with product, and seals the bags closed.

Some machines perform these processes vertically (vertical form fill seal or VFFS) and some do it horizontally (horizontal form fill seal or HFFS). VFFS machines have the advantage of occupying limited floor space and are more economical in cost, which makes them a top choice in many industries when square footage and budget are limited.

Multilane stick pack machines are very popular in industries that package small packets of powder or liquid products like condiments and drink mixes. These machines work similarly to form fill seal machines but create multiple packages at once.

FILL AND SEAL

Premade pouch fill and seal machines are a quickly growing flexible packaging machine type. This equipment fills premade pouches with product and seals them shut. Some pouch packing machines perform their operations in a rotary fashion and others in a straight line. Rotary machines have the advantage of occupying less floor space and have more favorable ergonomics for operators.

LEARN MORE ABOUT THE DIFFERENCES BETWEEN VFFS AND PREMADE POUCH MACHINES >>

Filling equipment

Packaging machines themselves do not measure or dispense product. Instead, a separate piece of equipment can perform these operations.

Often, a flexible packaging machine will be integrated with a filler or doser to accurately measure the weight or volume of product before it is dropped into each bag. Depending on your product properties, different filling equipment will be recommended:

- An auger filler is often used for powder products. This equipment uses a long screw-like mechanism to measure discrete quantities of product into bags.

- A multi-head scale is often used for solid products. This equipment uses a number of buckets to accurately weigh products before dropping them into bags.

- For liquids, a liquid pump, usually with a piston mechanism, will measure specific volumes of product into bags.

Fillers are usually placed above or off to the side of the packaging machine.

Bag types

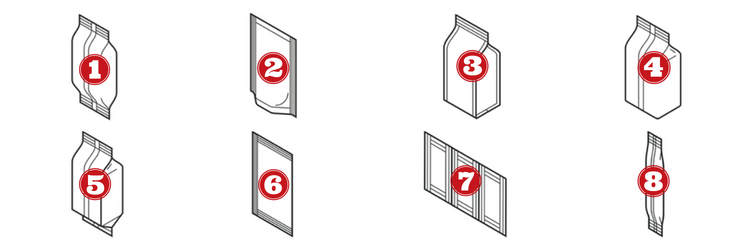

Flexible packaging machines can accommodate many different bag types. Examples of common bag styles are below:

- PILLOW BAGS are the most widely-used and economical packaging format, comprised of two flat panels sealed together on the top and bottom with a vertical seal down the back. This bag type is popular for value-brands, chips, single-serving snacks, and fractional packs of coffee.

- DOYPACKS are stand-up pouches with an oval-shaped base. This bag type is growing in popularity for premium products in many industries, including snacks, coffee, and powder supplements.

- QUAD SEAL BAGS have a rectangular bottom and can stand unassisted. This bag type has two side gussets and two panels joined together with four vertical seals, providing a more structured bag and modular look. This bag type is popular for premium coffee brands.

- FLAT BOTTOM BAGS are similar to quad seal bags, featuring two gussets, but only have a single vertical seal. This bag type is popular for coffee and pet food.

- GUSSETED BAGS are similar to pillow bags but have side gussets, offering more internal space.

- THREE SIDE SEAL BAGS are flat pouches sealed on three sides.

- SACHETS are small, flat 4-side sealed packets, often used for single-serving condiments and spices.

- STICK PACKS are very narrow pillow bags, used for single-serving powders and liquids.

Flexible packaging machine specifications

SPEED

Packaging equipment is often rated by speed or throughput, which is how many finished bags can be completed by the machine in a certain timeframe. This is usually represented as bags per minute (bpm), which is how many finished bags can be produced by the machine per minute.

Often a machine will be rated for a maximum number of bags per minute, while actual production speeds will vary based on many factors including operator skill, product properties, bag styles, and plant environment.

BAG PARAMETERS

Packaging equipment will also have bag size parameters, usually represented by width, length, and/or depth in millimeters (mm). This means a finished bag must fall within certain size constraints.

Some packaging machines can accommodate very large bags, and others work best creating much smaller packages. Your packaging machine manufacturer will use your bag parameters to decide which machine to recommend.

Packaging machines can also have bag weight parameters, meaning the machine can only support bags up to a certain weight. If a bag is very large and heavy, load-bearing support shelves can be added.

BAG TYPES

Another parameter will be the bag types a packaging machine can produce. Certain models can only create simple flat bag types while others can create more complex bags, like stand-up pouches.

ELECTRICAL & AIR REQUIREMENTS

Packaging machines need adequate power and air supply to operate. Specifications for these components will also be listed on most spec sheets.