Wrap around Labeler | Semi-automatic Wrap around Labeling Machine SBM-SARLM220

-

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: T/T, L/C

Overview

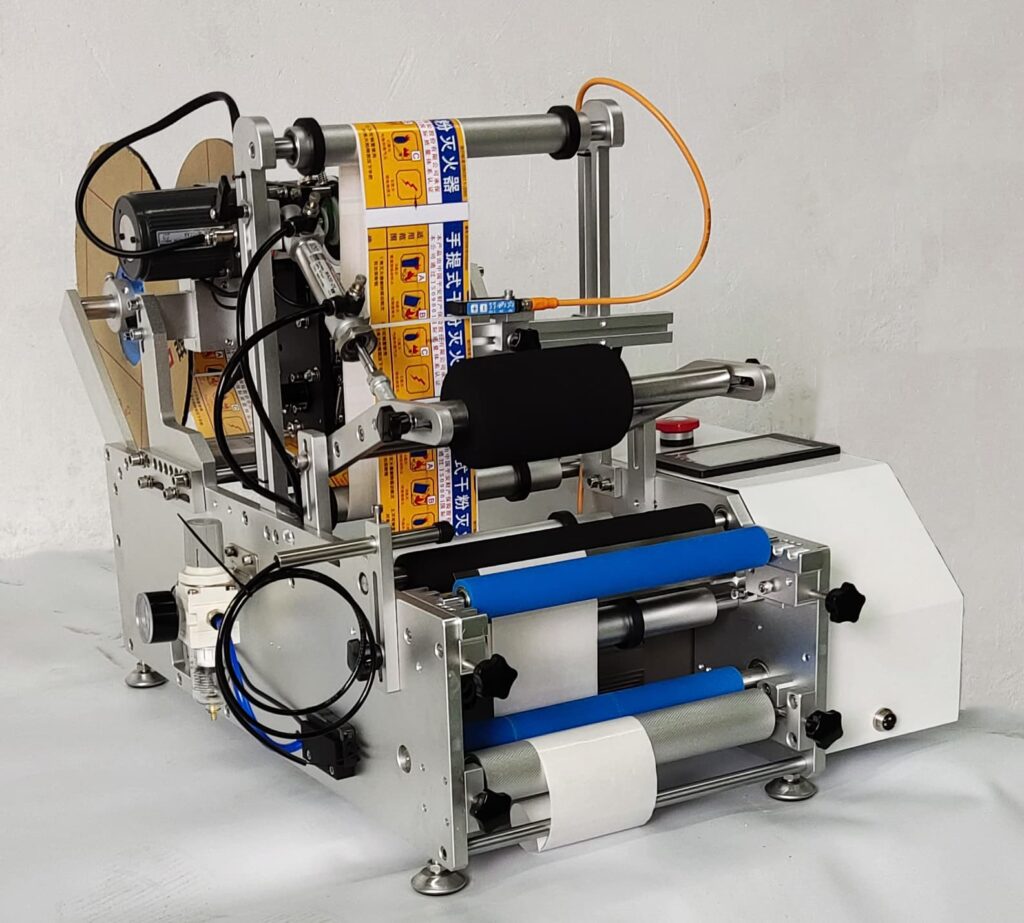

The labeling of cylindrical products like pipes, tubes, glass bottles or ampules poses particular challenges for manufacturers or packaging service providers in terms of precision. The SBM-SARLM220 semi-automatic wrap-around labeler is the perfect solution for such a task. Its exceptional durability makes it ideal for continuous duty and fulfills the most stringent requirements for labeling performance.

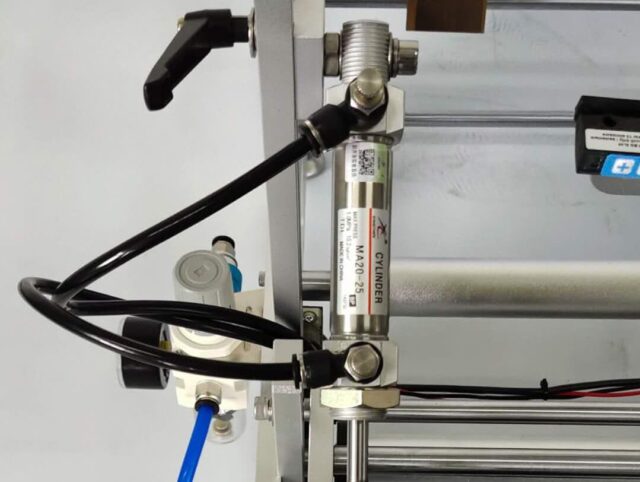

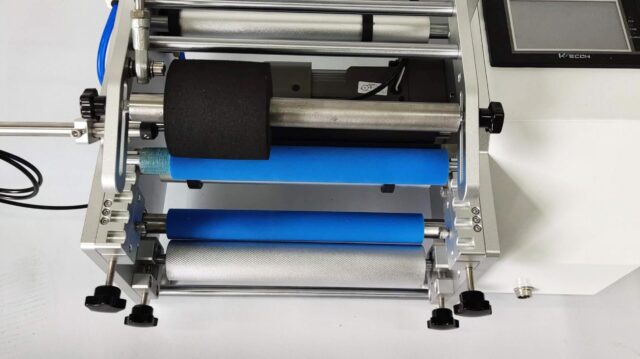

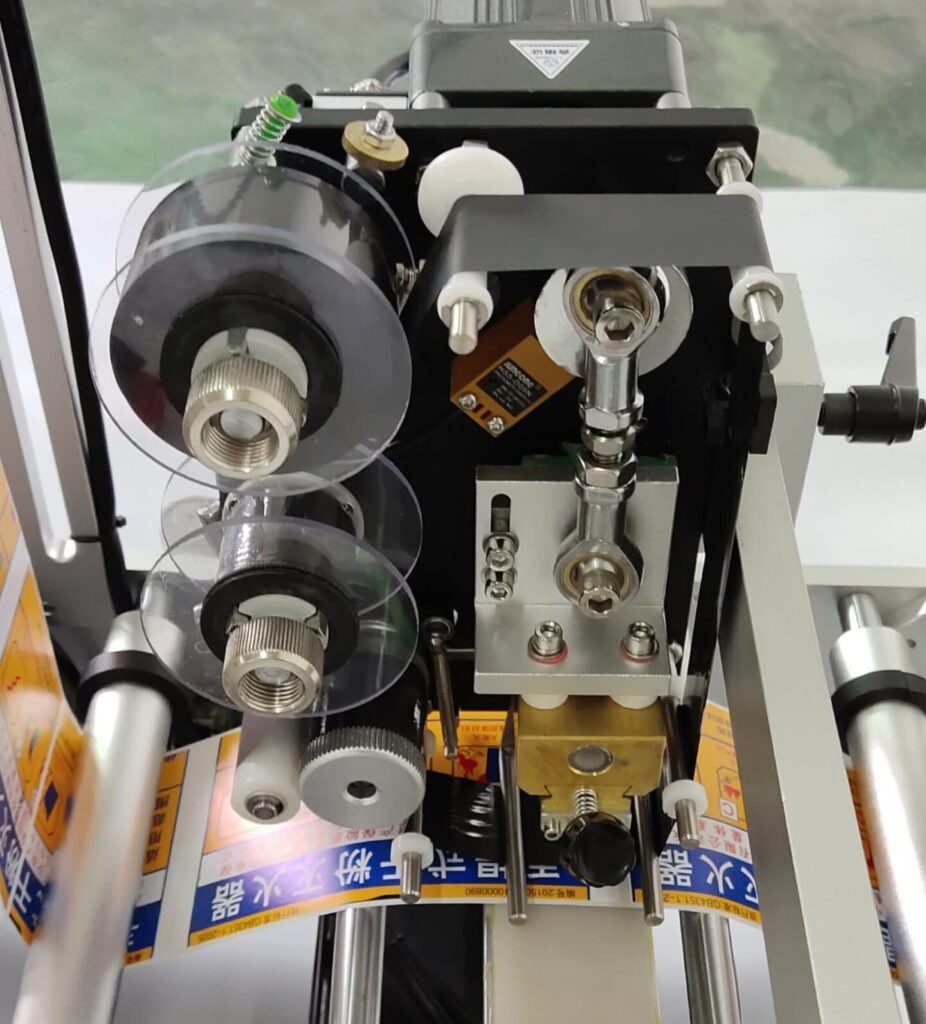

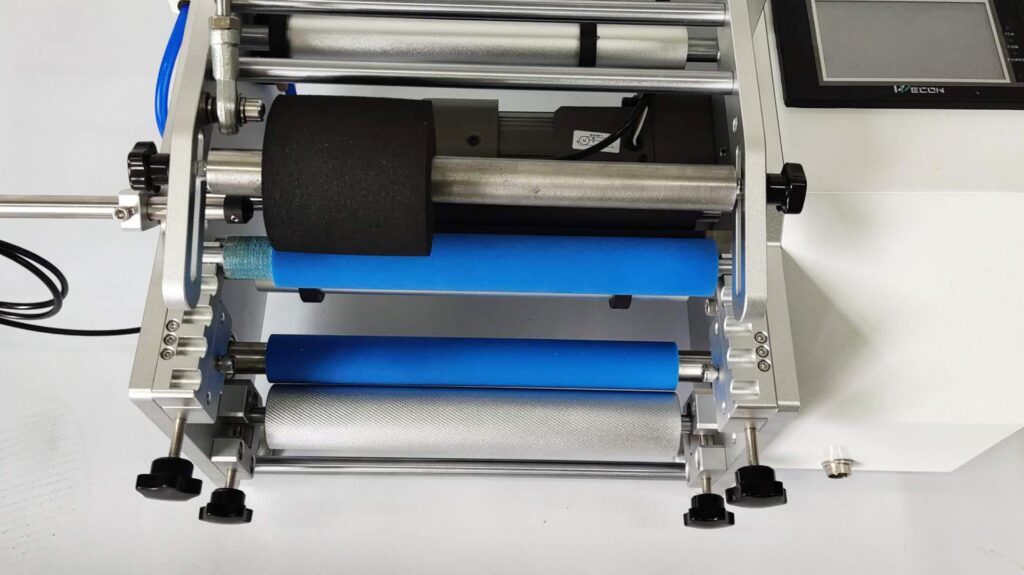

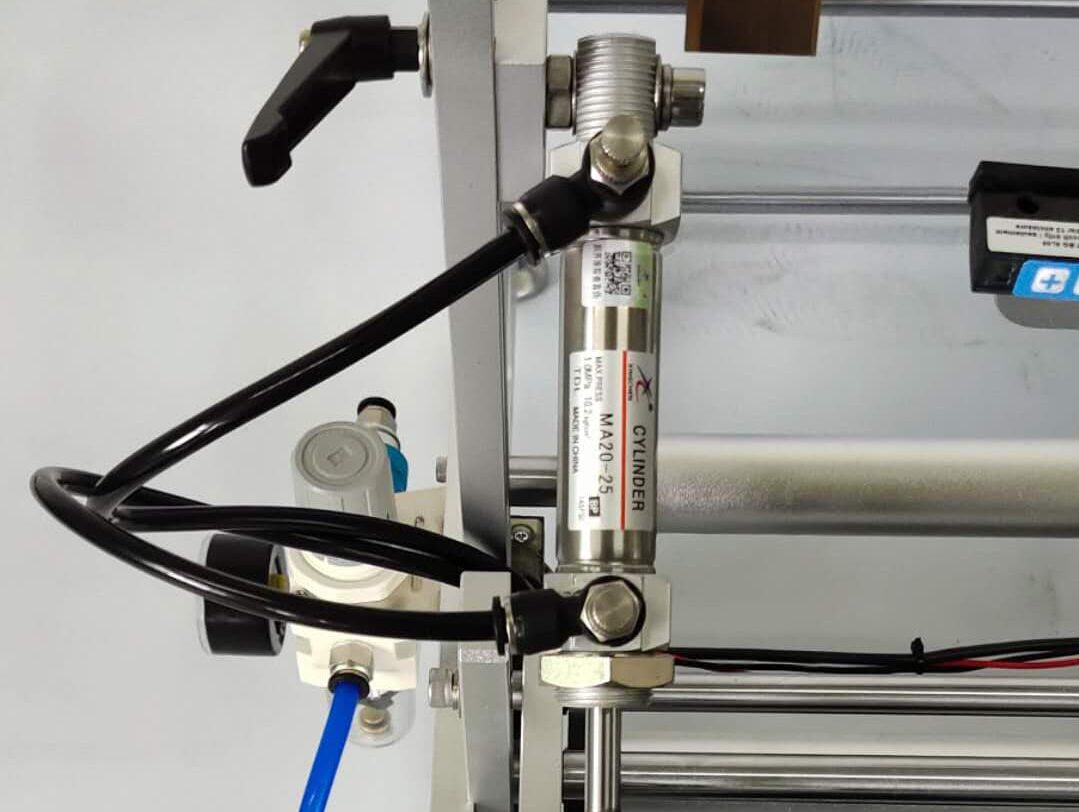

The product to be labeled is manually placed in a rotating roller prism and set in rotary motion. A pivot beak is lowered and rolls the label on with precise positioning. This ensures wrap-around application of the label with no misalignment. Then the product is removed by hand. The semi-automatic system is extremely easy to retool. A variety of printers can be used to print expiration dates or batch numbers on the product .

Circumference positioning detection device is optional to realize circumference positioning and labeling.

Basic concept of the semi-automatic wrap-around labeling system

The SBM-SARLM220 model series is used to label cylindrical products, such as wine bottles, on the circumference. To do this, the product is placed manually in the product turning station. The labeling process is triggered by actuating the foot switch or the optionally available 2-hand operation. The product is rotated and the label is applied precisely to the circumference of the label.

If front and back labels are on one label roll, the system can also place several labels on the circumference. The distance between the labels can be adjusted in the system format.

Depending on the operating personnel, the performance of this model series is between 20 and 30 products/min.

For large batches or high-consumption products, we recommend fully automatic labeling solutions. We can offer the fully automatic system for labeling round and square products such as cans, jars, vials and much more.

Options

- Printing unit

- Circumference positioning detection device

Products

Bottles, vials, jars, small buckets, cans etc.

Features for semi-automatic wrap-around labeling

- Easy handling and operation

- Fast and tool-free changeover to other formats

- Precise labeling

- Subsequent integration of printing units

- It supports labeling of conical bottles and has taper adjustment knob, which can meet labeling requirements of conical bottles by simple adjustment

- The spectrum of possible product diameters ranges from 13 to 135 mm

- Stable performance. PLC and optical fiber sensor control system, support 7 * 24 hours long time work.

- Made to last. in strict compliance with Good Manufacturing Pactices(GMP) standards, the semi-automatic wrap-around labeling machine is made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments. This durability translates into a solid choice for labeling machine longevity.