- Home

- Products

- Labeling Machine

- shrink sleeve labeler

shrink sleeve labeler

$12866 $11580

The SBM-L2500SS shrink sleeve labeler is a fast, efficient and easy-to-operate. The production rate can be up to 250 products per minute.

SKU: SBM-L2500SS Category: Labeling Machine

- General Details

Shrink Sleeve Labeler Model SBM-L2500SS

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: T/T, L/C

Overview

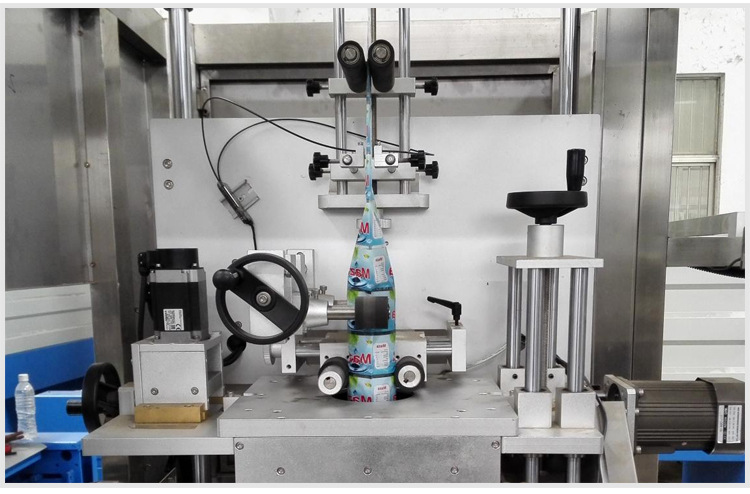

The SBM-L2500SS shrink sleeve labeler is a fast, efficient and easy-to-operate. The labeling system can handle tamper-evident, overall, middle, and full-body sleeve applications. The shrink sleeve labeling machine allows for production rates up to 250 products per minute. It will easily handle a wide range of container shapes and sizes.

Features

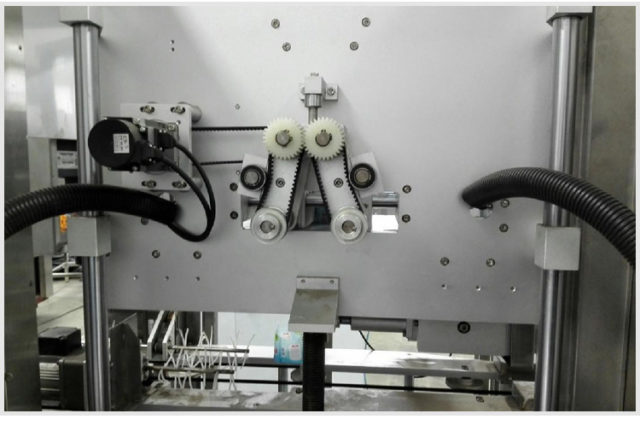

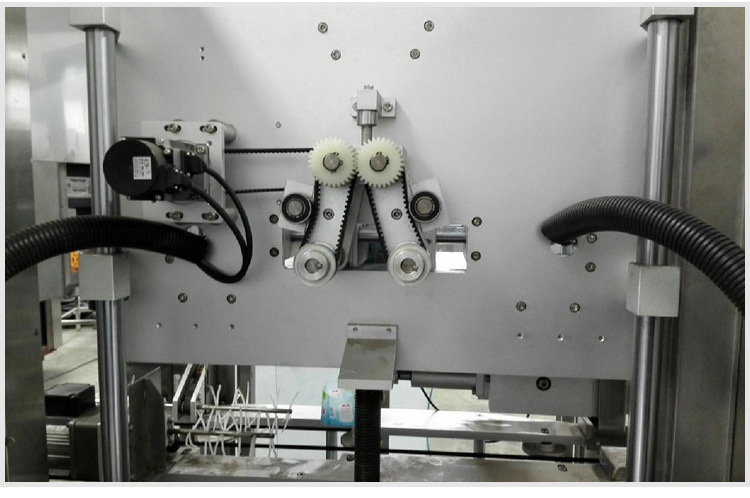

- Robust stainless steel and anodized aluminum construction.

- Safety guard provides the operator protection during labeling.

- HMI Touch screen ensure user-friendly operation.

- Cutting assembly equipped with servo motor for high accuracy.

- Easy to operate settings and easy product changeovers.

Options

- Integrated conveyor.

- Electric or Steam heat tunnels

Label Location

The scope of application

- Techical Info

The following is the standard model technical parameters, special requirements and features can be customized.

Model SBM-L2500SS Output Speed 100-250 bottles per minute Bottle Diameter Range 28-125 mm Sleeve Length Range 30-250mm Label Thickness Range 0.03-0.13mm Core Inner Diameter 5”-10”(Free adjustment) Material PVC, PET, OPS Power supply AC220v/50Hz or Optional Power Consumption 3kw Machine Dimension(L×W×H) 2100×850×2000mm Machine Weight 400kg - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

- Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO, THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

- Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the traveling fee on your country) should be on your account and you need paid for the technician USD50 per day. Also you can go to our factory to do training.

- After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

- Comments