- Home

- Products

- Labeling Machine

- Semi automatic round bottle labeling machine

Semi automatic round bottle labeling machine

$5510 $4959

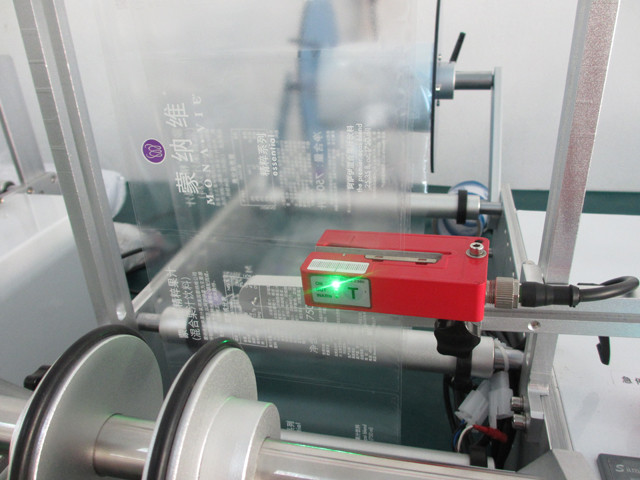

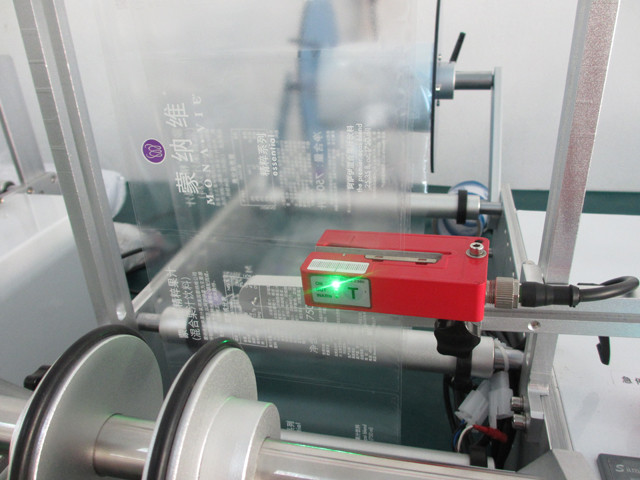

Semi automatic round bottle labeling machine is suitable for all kinds of cylindrical objects labeling, small taper round bottle labeling, such as xylitol, cosmetics round bottles, wine bottles and so on.

- General Details

Semi automatic round bottle labeling machine

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: L/C,T/T

Semi automatic round bottle labeling machine is suitable for all kinds of cylindrical objects labeling, small taper round bottle labeling, such as xylitol, cosmetics round bottles, wine bottles and so on. Can achieve full round / half round labeling, front and back labeling circumference, is back mark pitch can be adjusted. Widely used in food, cosmetics, chemical, pharmaceutical and other industries.

Working process

- Core works: the product or foot sensor detects a signal, the motor driven rotation of rotating the bottle and sent labels to bottles on the side of the label side of the cover label; finished out of the first label, set the time interval, and the other a label sent to the set position labeling, product labeling and cover rotating label, the label affixed to the product finish and covered Fortunately, two labels attached action is completed.

- Procedure: put the product -> Labeling and covered standard (device automatically) -> take out the labeling products.

Semi-automatic round bottles labeler

Features of the transparent labels round bottle labeling machine

- Dedicated to wine bottle labeling, can achieve circumferential surface of a single standard, double standard labeling is back, double standard spacing is adjustable.

- Labeling accuracy can be set in the wine bottle height position, set the interval before and after labeling.

- Intelligent control, manual control or automatic control, automatic control, photoelectric tracking detection of the workpiece, automatic labeling.

- Features a simple switch, DIP switch selectable single standard labeling select or double standard labeling, double standard state, is back label spacing can be adjusted freely.

- Optional label positioning detection device can be realized in the case of labeling, a label affixed to another.

- Health and safety, equipment, mainly made of stainless steel and high-alloy production, in line with GMP production requirements.

- High stability, using PLC + Italy Atlantis photoelectric sensor control, stable performance, support for 7 × 24h continuous work.

- Optional features and components:

Hot coding function;

Circumference circumferential positioning function;

Other features (according to customer requirements).

- Techical Info

The following technical parameters for the standard model, other special requirements and functions can be tailored.

Model No. SBM-lm25 Suitable label length (mm) 20-100mm Applicable Label width (backing paper width / mm) 20-180mm Applicable Products diameter (for round bottle) φ15mm ~ 120mm Applicable standard roll diameter (mm) φ240mm Applicable standard roll diameter (mm) φ76mm Labeling accuracy ± 0.5mm Labeling speed (pcs / min) 15 ~ 25pcs/min Weight (kg) about 45kg Frequency (HZ) 50HZ Voltage (V) 220V Power (W) 200V Device dimensions (mm) (L × W × H) 920mm × 420mm × 500mm - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

After sales service for semi automatic transparent labels round bottle .

- Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

- Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account and you need paid for the technician USD50 per day. Also you can go to our factory to do training.

- After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

- Comments