- Home

- Products

- Labeling Machine

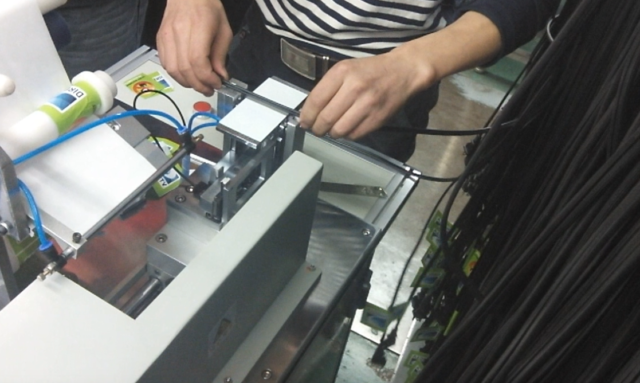

- semi-automatic cable labeling machine

semi-automatic cable labeling machine

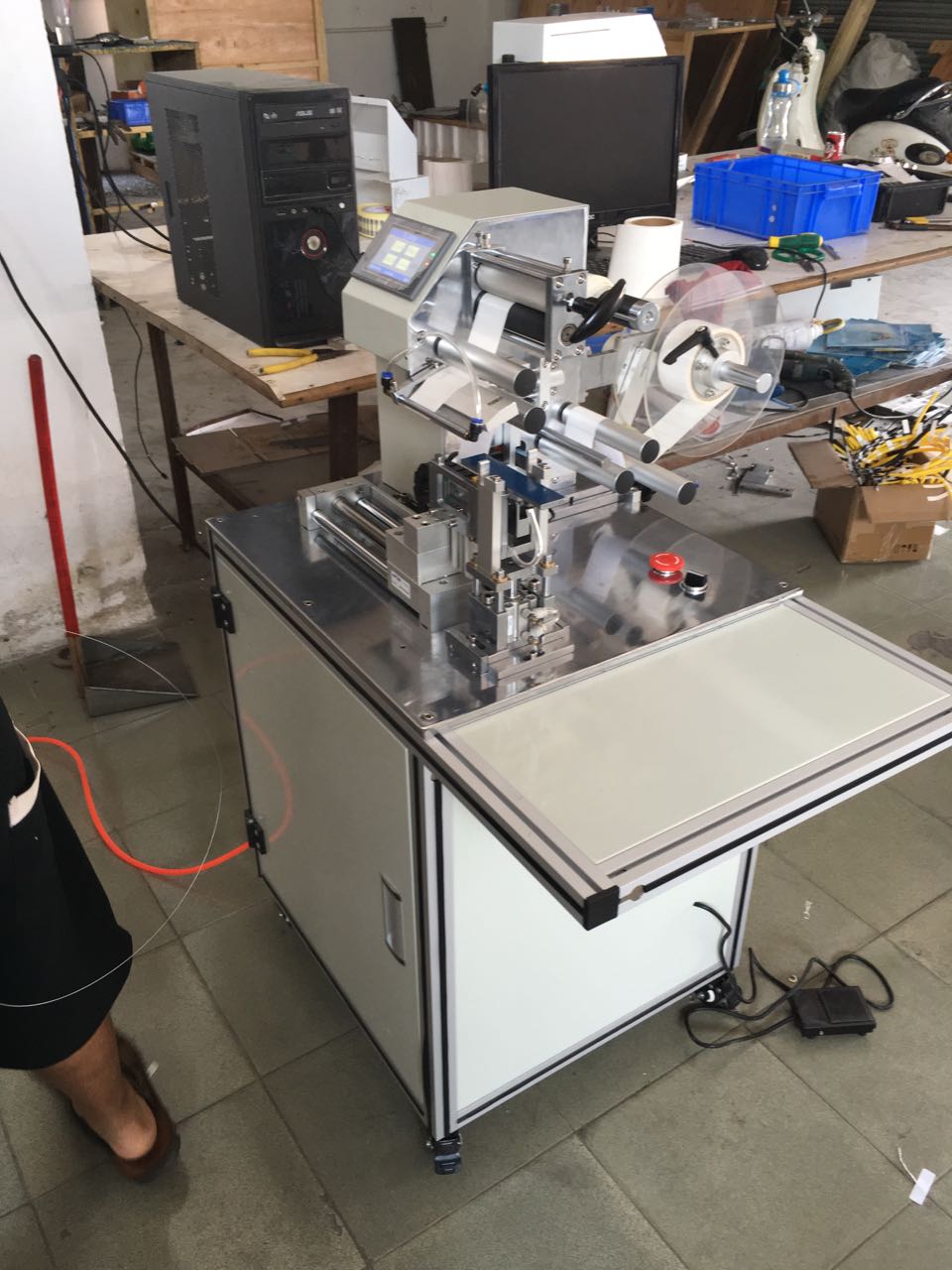

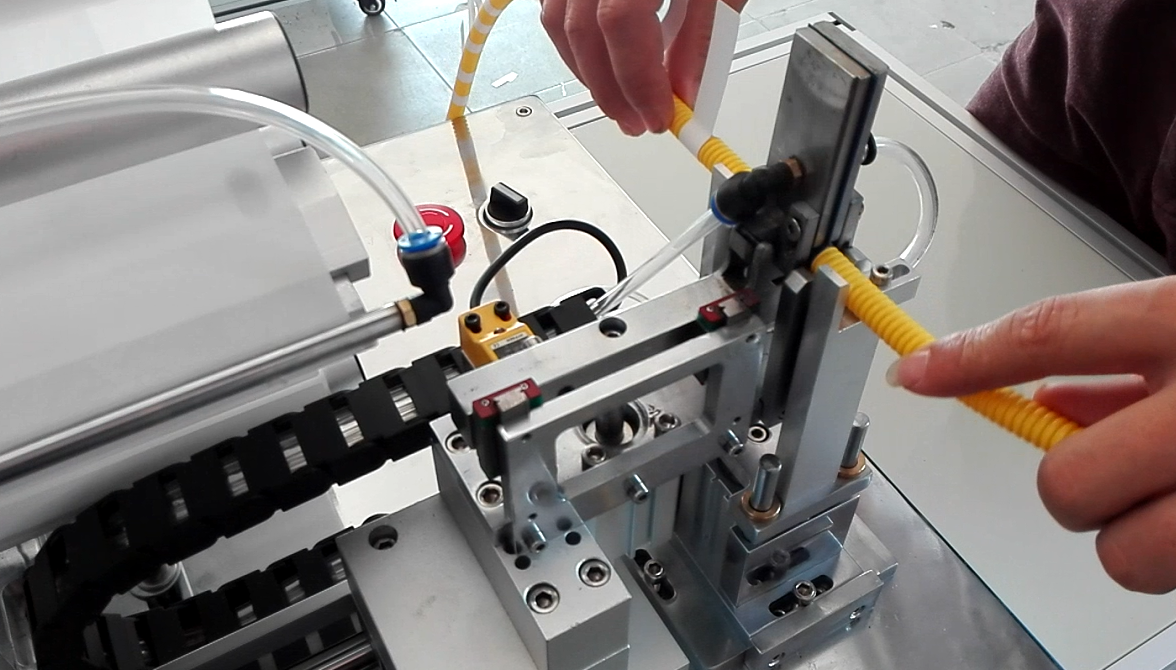

full view of the semi-automatic cable labeling machine

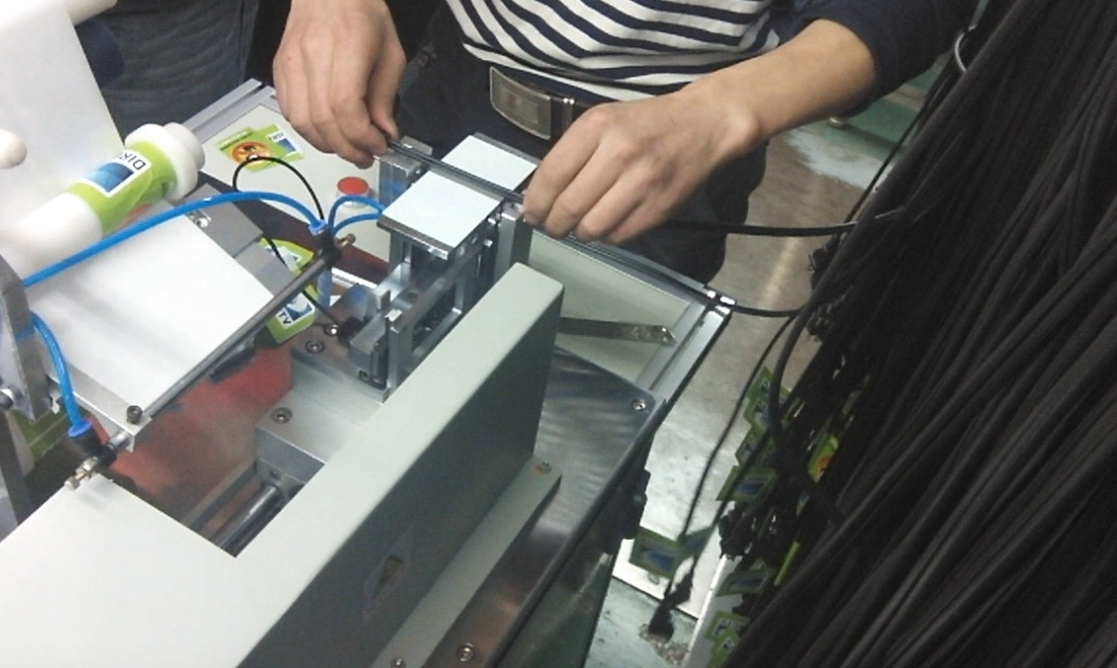

full view of the semi-automatic cable labeling machine in the workshop

$6897 $6208

Semi-automatic cable labeling machine is suitable for all kinds of cable. Such as power cord, wire harness, usb wire.

- General Details

Semi automatic cable labeling machine

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: L/C,T/T

Semi-automatic cable Labeling SBM-LM25108 is suitable for various kinds of cables. Such as round cables, flat cables. This machine can be widely used in many industries include electronics factory, electric factory, wire factory and so on.

The features of semi-automatic cable labeler

- Can be connected with the assembly line or separate labeling.

- Occupies a small space.

- Applicable all kinds of label.

- High level of electronic control system, using photoelectric switches from German and MITSUBISHI PLC.

- High accuracy, using high quality vacuum generator to stabilize the suction pressure.

- Universal intelligent control, automatic photoelectric tracking, can prevent the wrong label and the leakage label.

Working principle for cable labeling machine

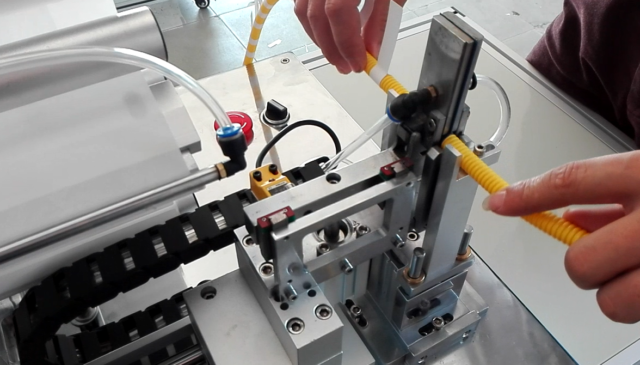

- Transmission system: The stepper motor provides power to strip labels through the synchronous belt driving the traction mechanism and the material receiving mechanism, so as to achieve stripping labels and recycling the Glassine backing sheet.

- Control system: This machine is controlled by using electric and gas. The signal from electric eye (SICK sensor) and pedal switch will be transferred to PLC for processing, in order to achieve all processes of stripping labels, labeling and counting.

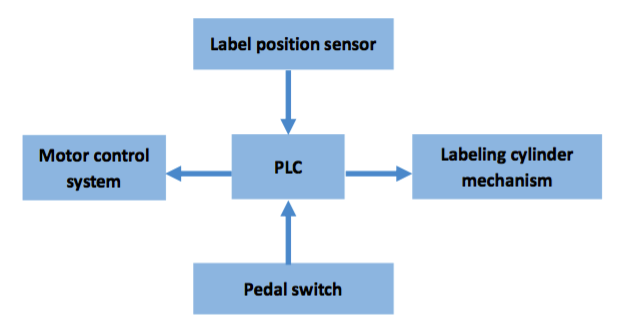

Control system

Principle description: Labeling machine is based on PLC as the core, receiving signals and controlling the work of all systems. When stepping the pedal switch, the signal will be sent to the PLC and processed according to a set of programs. Then complete the processes of stripping label and feeding label by starting on the stepper motor control system. At the same time, the label position sensor (also known as electric eye) will always pay attention to the distance by the label going through. When a label goes through, the sensor will send the signal to PLC immediately. Then the PLC, according to a set of programs, sends the signal to stepper motor control system to stop and starts on the labeling system so as to complete the process of labeling.

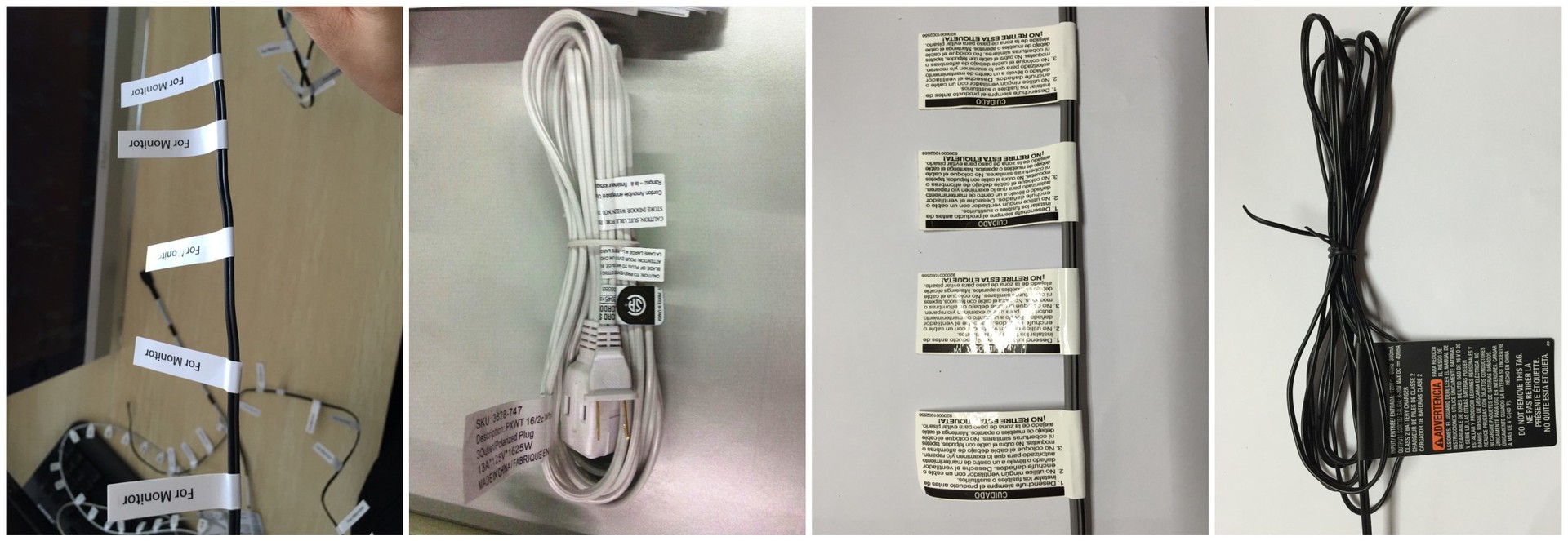

Samples from semi-automatic cable labeler

- Techical Info

Model No. SBM-LM25108 Applicable cable dimensions 3-8mm Label size (W) 6~50mm / (L) 40~120mm (label size can be customized) Accuracy ±0.3mm Labeling speed 20-30pcs/min Voltage 220v Frequency 50HZ Air pressure 0.6Mpap Power 140W Weight 60kg Machine size Machine size: (L) 750mm (W) 500mm (H) 1100mm - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

- Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

- Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account and you need paid for the technician USD50 per day. Also you can go to our factory to do training.

- After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

- Product video

- Comments