- Home

- Products

- Labeling Machine

- Round Bottle Tabletop Labeling Machine

Round Bottle Tabletop Labeling Machine

the semi automatic round bottle labeling machine and samples

the semi automatic round bottle labeling machine without date coding printer

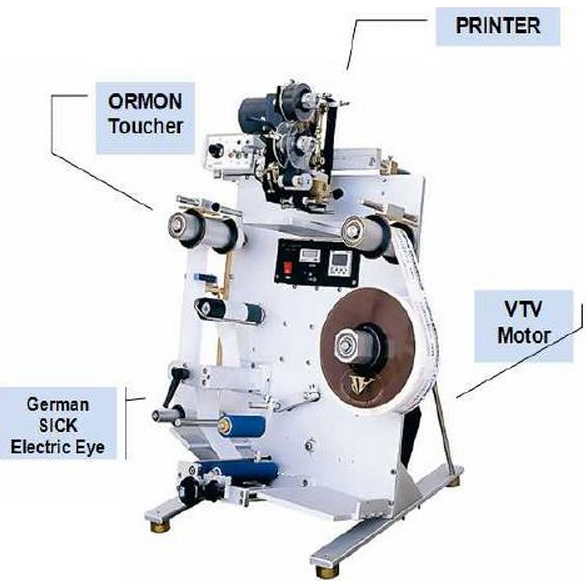

main parts of the semi automatic round bottle labeling machine with date coding printer

$2238 $2015

This semi-automatic round bottle labeling machine with/out coding printing function fits for a wide range of products.

- General Details

Round Bottle Tabletop Labeling Machine

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: L/C,T/T

This semi-automatic round bottle labeling machine with/out coding printing function fits for a wide range of products.

The machine can basically achieve all the required of product labeling, especially for low-volume, variety and changeable specifications labeling which can largely improve the labeling production efficiency and reduce equipment investment costs.

It widely used in cosmetics, food, toys, daily chemical, electronics, pharmaceutical, plastics, printing and other industries, such as flat shampoo bottles, packing boxes, cosmetic flat bottles, bottle caps, plastic shell, SD cards, batteries, flat, arc, circle face, concave, convex or other attached label.Main features and performance from model SBM-LM70 semi-automatic round bottle labeling machine

- This labeling machine is controlled by PLC, operated by a text editor and detected by photo electricity with excellent appearance.

- Menu allocation is convenient and swift with flexible function options.

- This machine is equipped with a mucilage thickness adjustment device to achieve no bottle no labeling.

- It can label both one side of one bottle and double sides of one bottle.

- The outer parts of this labeling machine are made of high-quality 304 stainless steel or dealt wit

h plastic spraying with high anti-corrosion.

Core principle from round bottle labeling machine

The sensor detects the product in place or foot in place to issue product signals, adsorption label suction head down and follow-labeling and then returned to adsorption next label, waiting for the next signal, a labeling action completed.

Operation

Put product – Determined in place (equipment detection and control or manual control) – Labeling (device do automatically) – Take out labeling products.

Main parts of the round bottle labeling machine

- Techical Info

Model No. SBM-LM70 Label width 10-130mm Power consumption 350W×2 +250W×2=1.2KW Filling volume 50,100,200,250(ml)(customized) Producing speed 25-30pcs/min Filling accuracy ±1% Label length 20-400mm Labeling speed 0-40B/M Bottle diameter Below 100mm Labeling accuracy ±1mm Power supply 200W, 380V, 60HZ, 3PH Label reel inner diameter 75mm Label reel outer diameter 300mm Net weight 50kg Machine Dimension 500×480×800mm - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

- Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

- Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account and you need paid for the technician USD50 per day. Also you can go to our factory to do training.

- After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

- Comments