- Home

- Products

- Labeling Machine

- Round bottle automatic positioning labeling machine

Round bottle automatic positioning labeling machine

Round bottle automatic positioning labeling machine

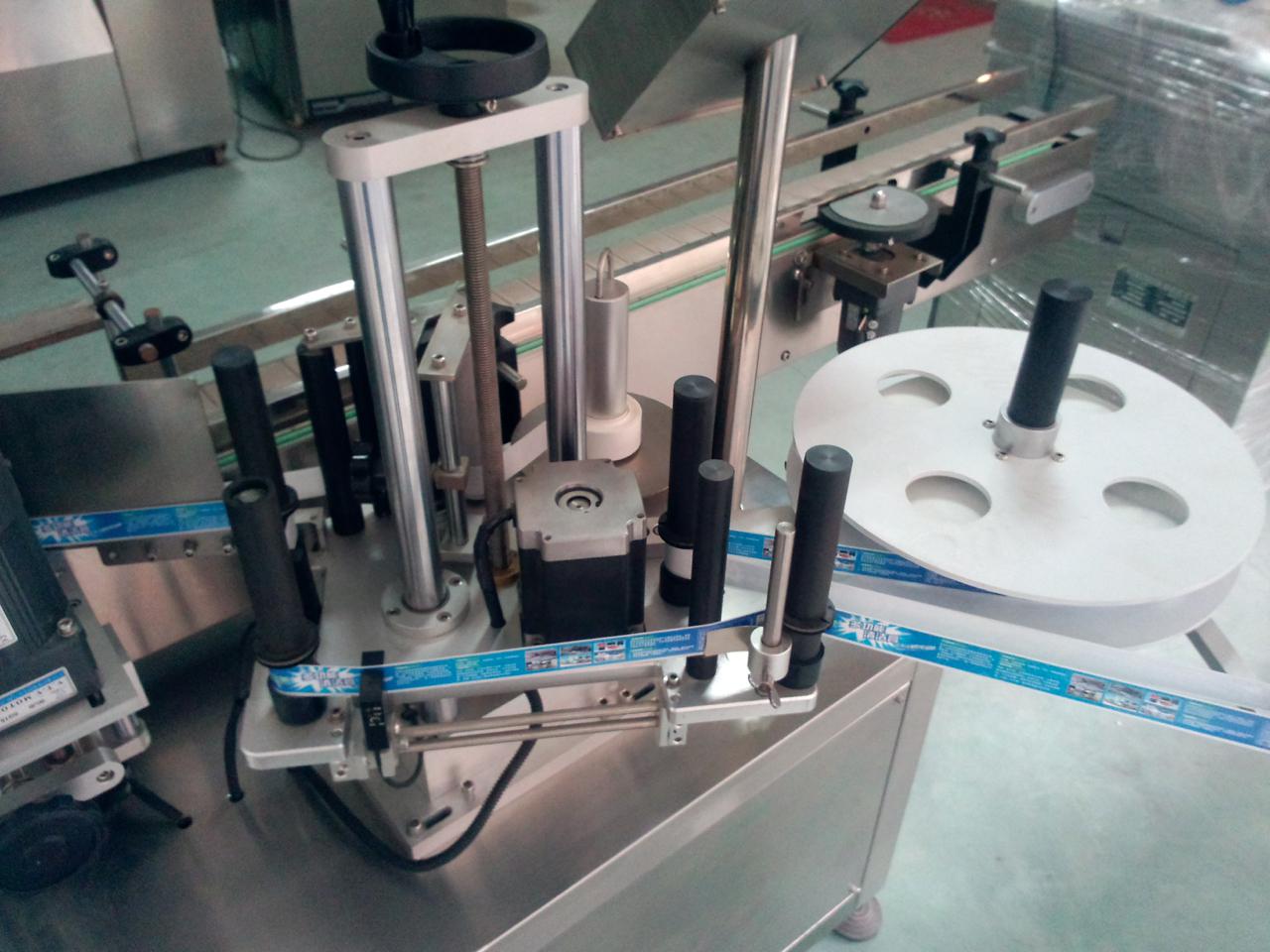

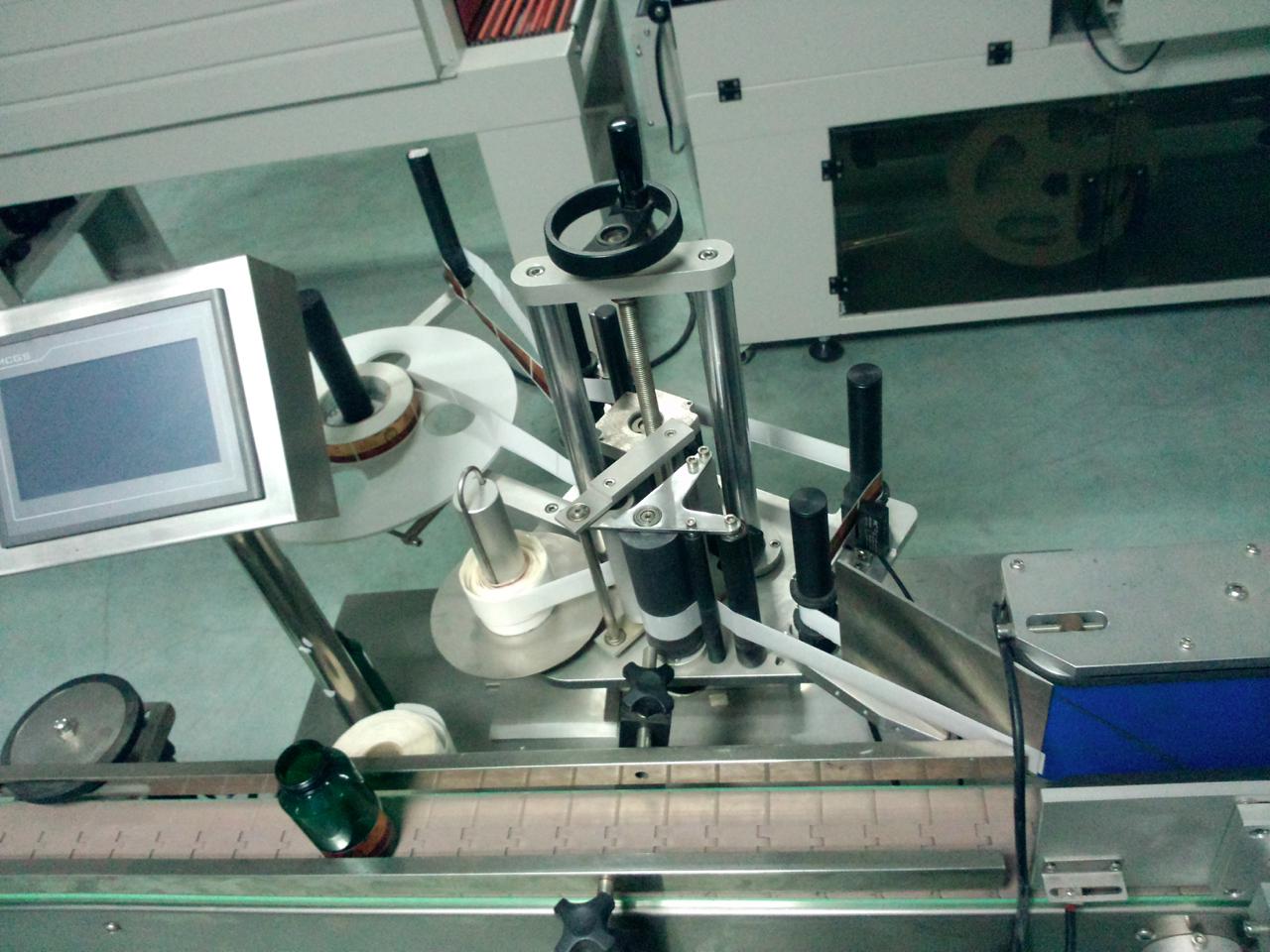

round bottle automatic positioning labeling machine's details

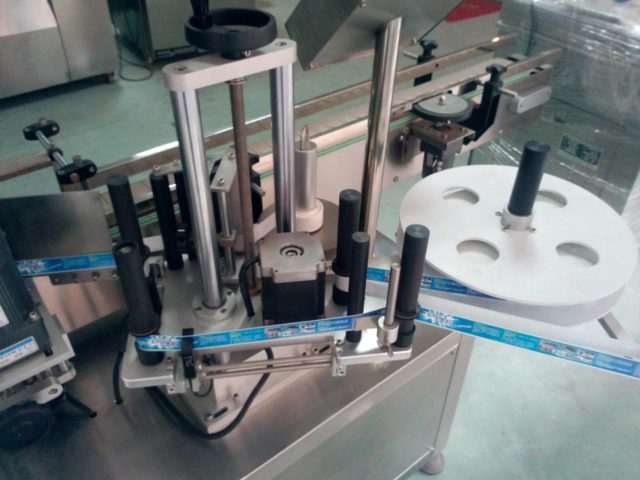

operating process of round bottle automatic positioning labeler

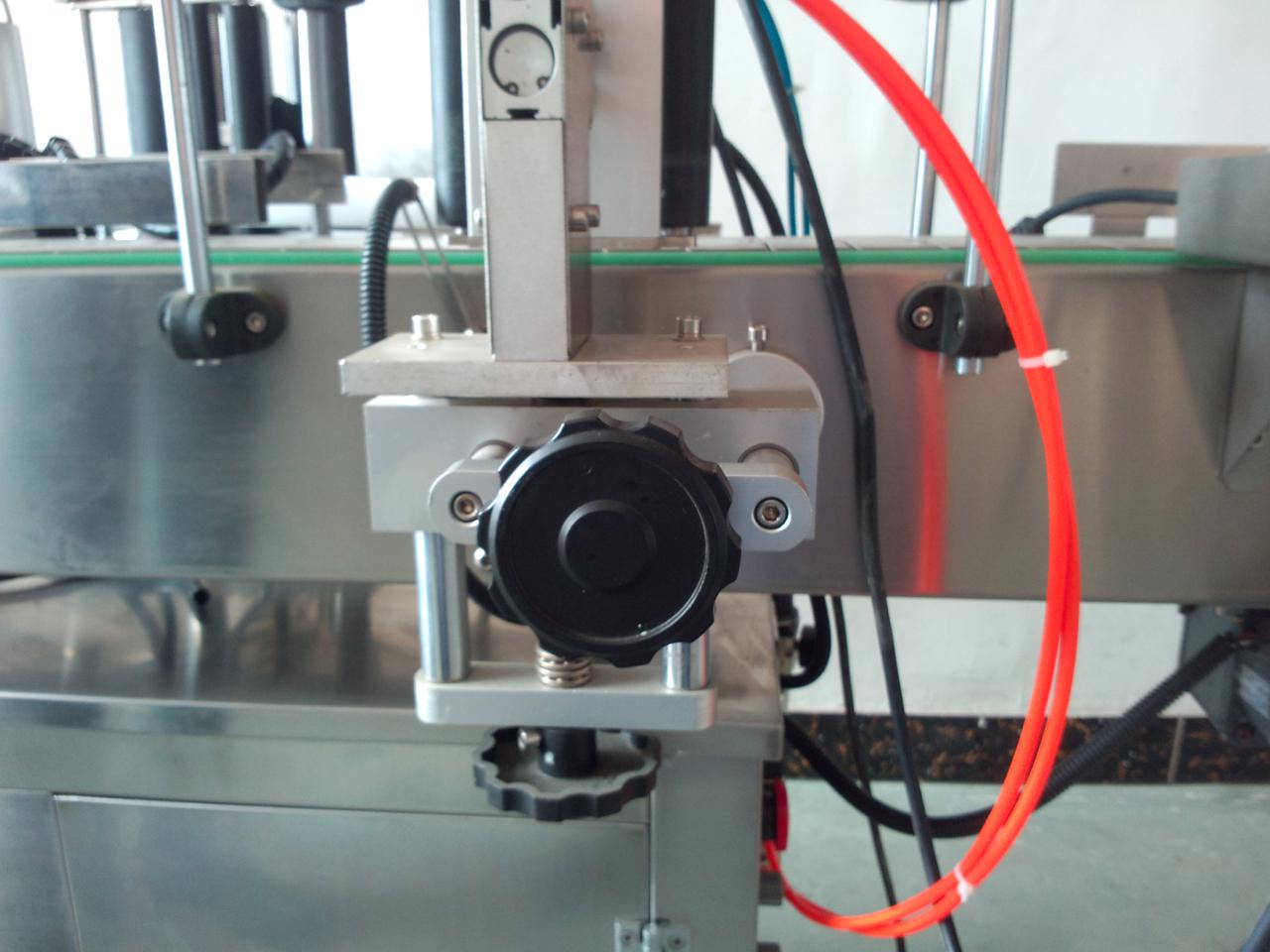

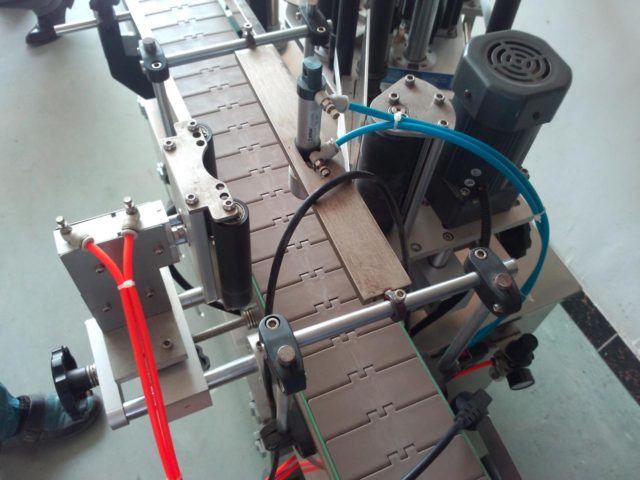

product details of the round bottle positioning labeling machine

$8875 $7988

Round bottle automatic positioning labeling machine is widely used in chemical, cosmetics, pharmaceuticals, food industries, provide solutions for the packaging line.

- General Details

Round bottle automatic positioning labeling machine/labeler

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: T/T, L/C

Applicable label: Self-adhesive labels, Self-adhesive film, electronic supervision code, bar code, etc.

Applicable product: Required to be labeled on the Circumference of surface or other Curved surface.

Applicable industry: Food and beverage industry, pharmaceutical industry, cosmetics industry, chemical industry, electronic industry, metal industry, plastic and other industries.

Application examples: PET round bottles, plastic round bottles, glass round bottles, Canned food bottles, wine bottles, and other special shaped bottles, according to customer’s requirements.We can supply you the optional rotary table for your reference, which can be connected directly before the labeling machine, the operators can put the bottles on the rotary table, then the rotary table will send the bottles to the labeling machine to the labeling machine automatically.

We can also supply you the code machine for your reference, to print production date and batch number, shorten the bottle packaging process, improve the production efficiency.Features of the round bottle automatic positioning labeling machine

- With widely applicability, which can labeling on the whole or the half of the round bottles, if you want to change the type of the bottle, the adjustment is very simple;

- With high labeling quality, which adopts high density sponge belt to smooth the labels on the bottles, after the rolling, there is no wrinkles, improve packaging quality;

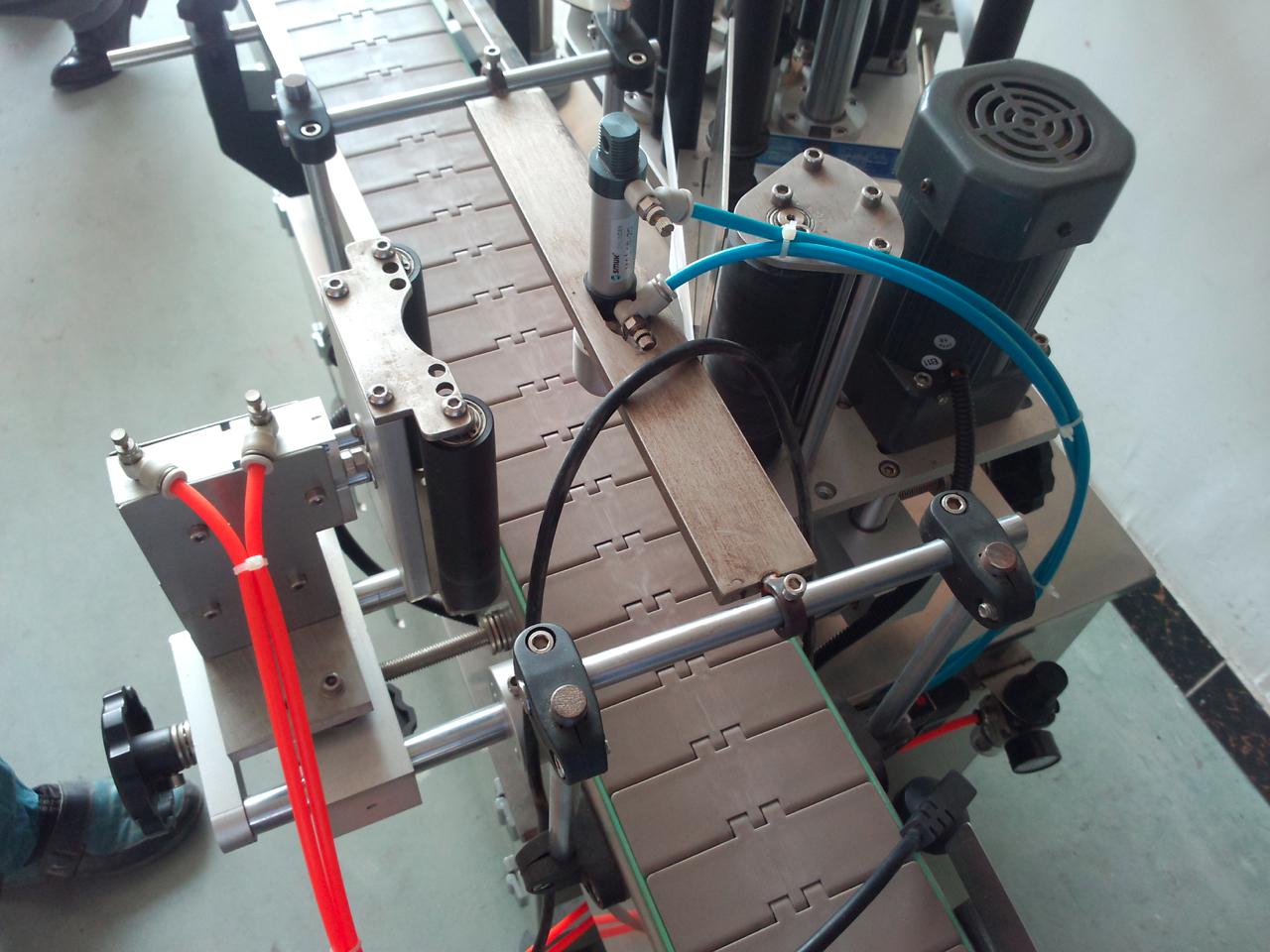

- With flexible labeling application, the bottles are vertical when labeling, we use the split device to separate the bottles, the machine can operate independently, can also connect with the other machines, such as the filling or capping;

- With intelligent control system and automatic photoelectric tracking function, if there is no product, the machine will not labeling on it, it can correct the labels and detect the signal of the label automatically, so as to prevent missing labels and the waste of the labels.

- According to your requirements to adjust the labeling speed, the delivery speed, the bottles split speed.

- With high labeling accuracy, adopts the electronic eye detection, the PLC system control the step motor to send the labels, which precision is very accurate;

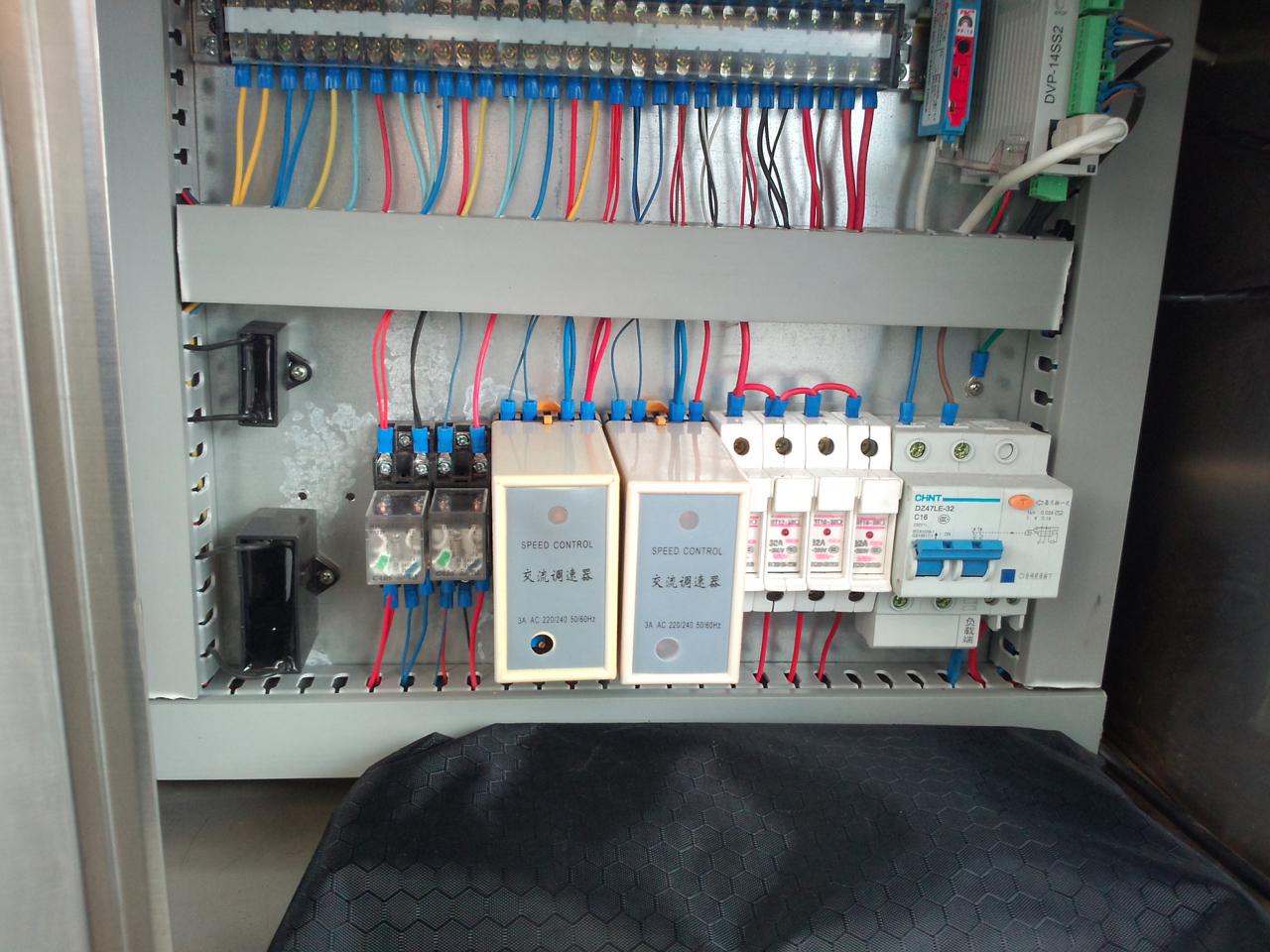

- High stability, the control system is consist of Delta PLC, Weinview touch screen and Keyence sensor, which can support the equipment operate for a long period;

- The touch screen operation interface makes the parameter adjustment simple and quick, easy to operate;

- Most part of it adopts stainless steel and aluminum alloy manufacturing materials, with novel appearance and compact structure achieve the production standard;

- With fault alarm function, production count function, reminding if the setting number reached, parameter setting protection function, which makes the production management easy and convenient.

- Techical Info

Model No. SBM-LMRB1202 Production capacity diameter 20-160 (mm), 30-130 bottles / min Labeling precision ≦ ± 1mm (depending on the verticality of the bottle) Pass rate ≥ 99% Power supply 220V 50Hz Total power 1.2KW Machine dimension 1650 × 700 × 850 mm(L × W × H) Machine weight 200kg - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account and you need paid for the technician USD50 per day. Also you can go to our factory to do training.

After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above). - Comments