- Home

- Products

- Packing Machine

- HFFS Packing machine for coffee powder Bag pouch

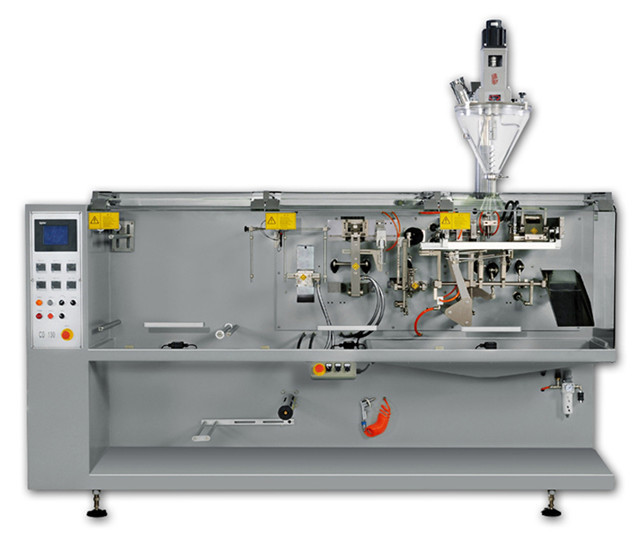

HFFS Packing machine for coffee powder Bag pouch

The front of horizontal packing machine for coffee powder Bag pouch

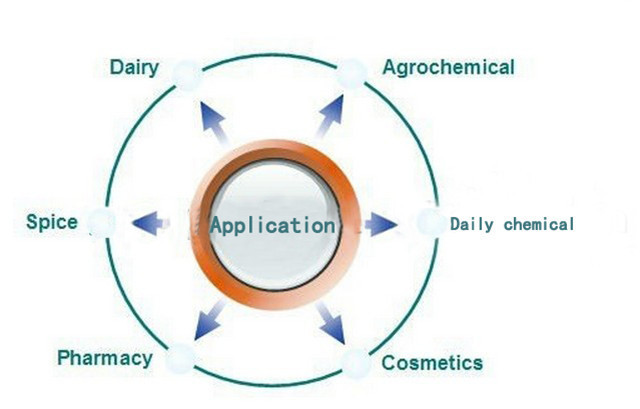

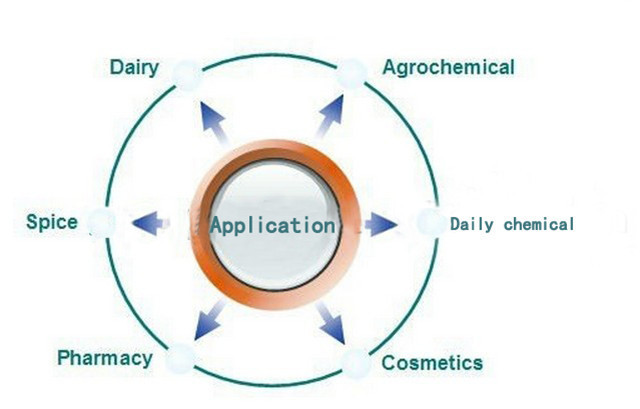

Applications of the horizontal FFS packaging machine for coffee powder bag pouches

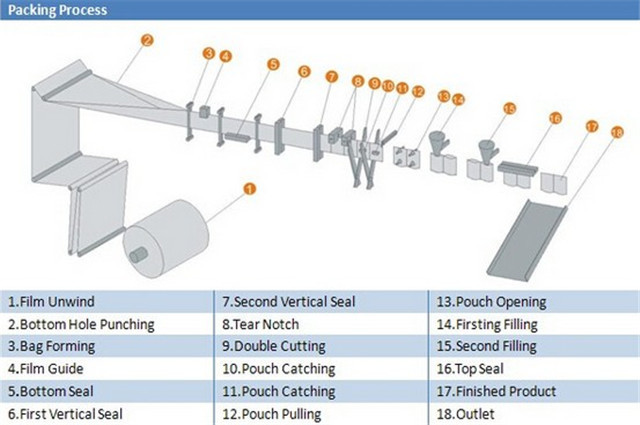

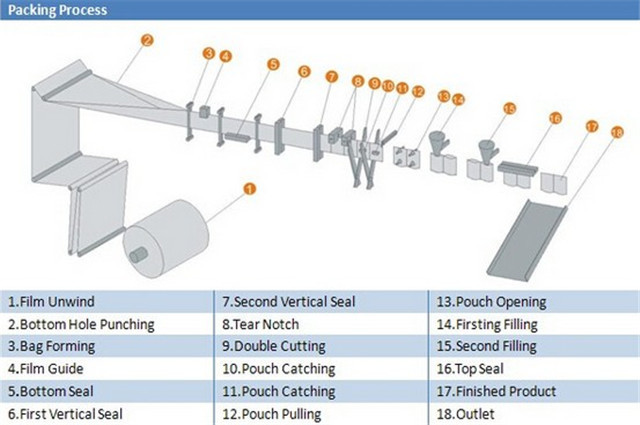

Packing process of the horizontal FFS packaging machine for coffee powder bag pouches

$48031 $43228

Horizontal forming, filling and sealing packing machine is applicable for such sectors including foodstuff, pesticide, pharmaceuticals, daily chemicals etc.

- General Details

HFFS Packing machine for coffee powder Bag pouch/Packaging equipment for liquid, powder, granules

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: T/T, L/C

Packing from 1-25g

Speed almost 40bags/min

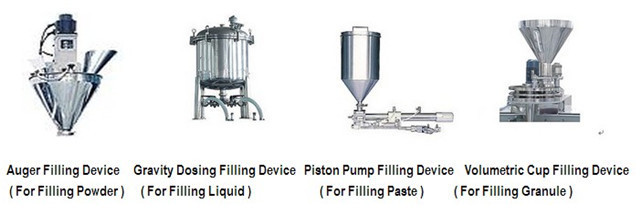

Its appearance is artistic, microcomputer (PLC) programmable control, photo electricity transduction. The main electrical components are imported original, performance reliable, operation and use convenient. It suits for the bagging of the complex film for the foodstuff seasoning, oral medicine to be taken after being mixed with boiling water, milk powder, additive, animal medicine, pesticide, dye and chemical reagent etc. It may meet the demand of the different industries for the high quality product’s packing.It is applicable for such sectors including foodstuff, pesticide, pharmaceuticals, daily chemicals etc. The machine can choose from different filling methods according to nature of material including liquid, powder, granule, paste etc.

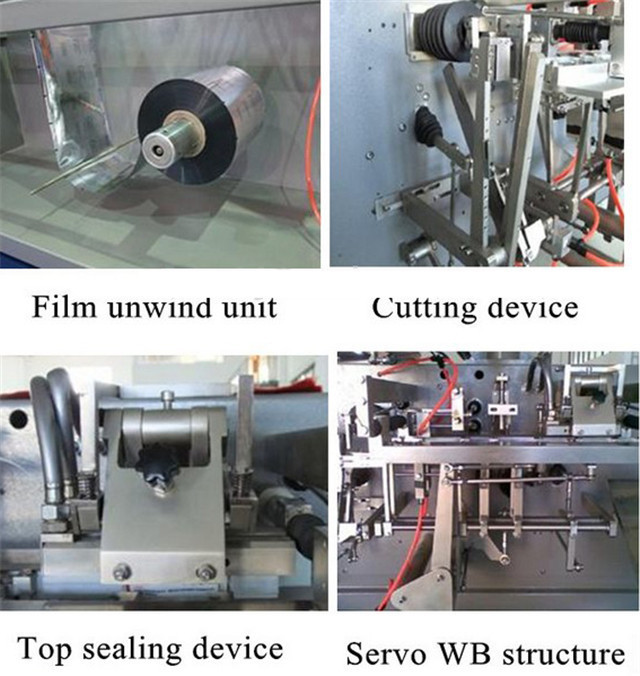

Features of horizontal FFS packaging machine liquid sachet powder form fill seal equipment

- Mainframe Frequency Conversion System: Imported AC motor and frequency conversion, stable and reliable operation; low speed and large torque ensure excellent performance even under sharp fluctuations of load.

- Servo Blanking System: Panasonic servo motor controls rotation of blanking bolt directly by pulse number; stable and reliable performance,convenience of regulation.

- Package Making System: The package making and sealing and filling systems are independent to each other in this system. The two systems are linked and coordinated by mechanical coupling and programmable logic controller (PLC). Therefore, the system is suitable for a variety of products and sizes of package.

- Finished Product Sealing System: Fully automatic production facility that finishes package making, metering, filling, sealing and other packaging processes by heat-sealing packaging material (polyethylene membrane, multilayer composite membrane etc.). The package shall be three-side or four-side sealed flat package. Fillers of different types may package a variety of products.

- Integrated Control System: It is composed of PLC, frequency converter etc., featuring a high level of integration, strong control capabilities and high reliability of operation. Touch screen technology eases and facilities operation. The optoelectric transducer,encoder, proximity switch etc. are all equipped with imported and advanced sensing elements, so the mechanical and electricalintegration of the entire frame is embodied perfectly.

Configuration of HFFS packaging machine for liquid powder granules cream packing

No. Name Place Brand 1 Touch screen Taiwan Eview 2 PLC Japan Mitsubishi 3 servo motor Japan Panasonic 4 Coder Japan Omron 5 Color-Code-Photo-Switch Japan Omron 6 Thermostat Korea Autonics 7 Power Taiwan Mean Well 8 button switch German Schneider 9 frequency converter Japan Panasonic 10 Main motor China Huang yan 11 worm speed reducer China Jiao xin 12 electromagnetic brake China Shuang neng 13 Relay Japan Omron 14 heating rod China Duo lai bo 15 thermocouple China Duo lai bo - Techical Info

Machine operation Horizontal form fill and seal(HFFS) Pouch origin Form the reel Pouch transport system intermittent Machine frame Stainless steel SUS304/ Carbon steel, the surface plastic coating Except internal mechanisms Parts painted Stainless steel colour/Stainless steel SUS304,and Aluminum alloy Parts in contact with product Stainless steel SUS316L Reel diameter 400mm Reel Width 440mm Reel core 76mm Filling stations 1 (with 1 heads) Machine dimension (L)2850×(W)970×(H)1390mm Machine weight 1000kg Pouch dimensions Minimum: 60mm×80mm;Maximum: 140mm×220mm Packaging speed Maximum:90ppm Pouch volume Maximum:300c.c Electrical 6.0kw Air consumption 50L/min 0.6Mpa Electrical Data 200-415V/50-60Hz/N+G

(According to customer requirements customization)Noise level ≤70dB Safety CE standards - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

- Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

- Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account and you need paid for the technician USD50 per day. Also you can go to our factory to do training.

- After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

- Comments