- Home

- Products

- Mask Machine

- Fully Automatic Disposable Earloop Mask Making Machine

Fully Automatic Disposable Earloop Mask Making Machine

$73500 $70000

SBM-MM100 series full-automatic mask production line is our latest product, with fine workmanship, stable performance and high production efficiency.The daily production capacity is 150000 (24h).

- General Details

Fully Automatic Disposable Earloop Mask Making Machine

-

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: T/T, L/C

Overview

SBM-MM100 series full-automatic mask production line is our latest product, with fine workmanship, stable performance and high production efficiency.

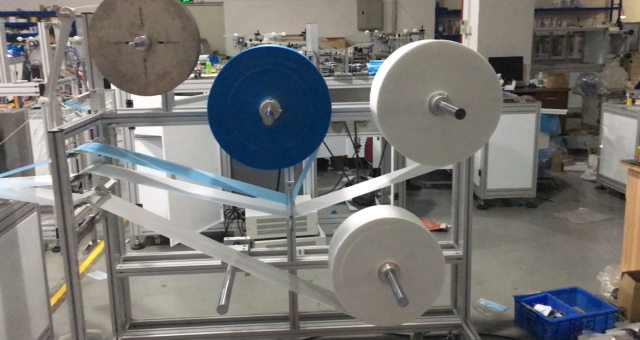

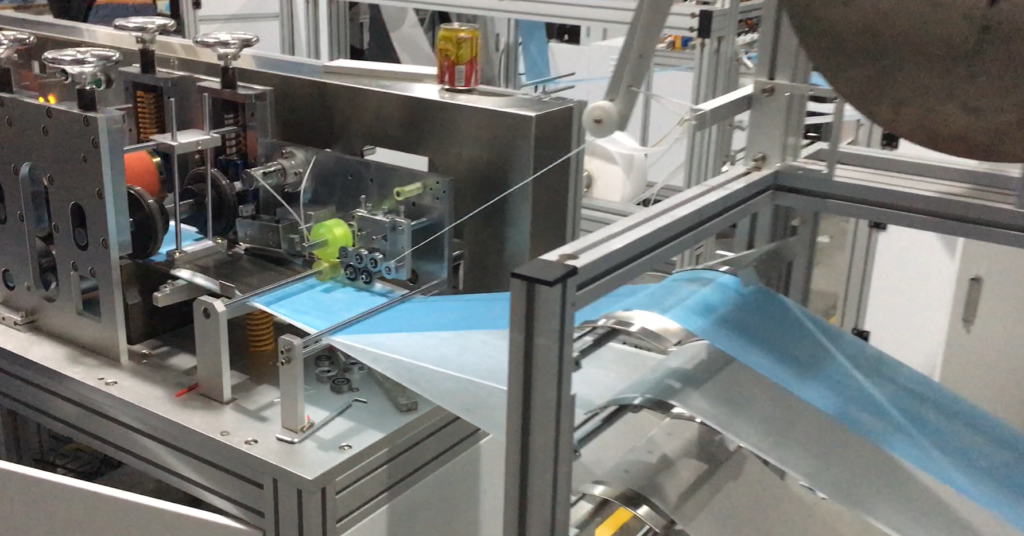

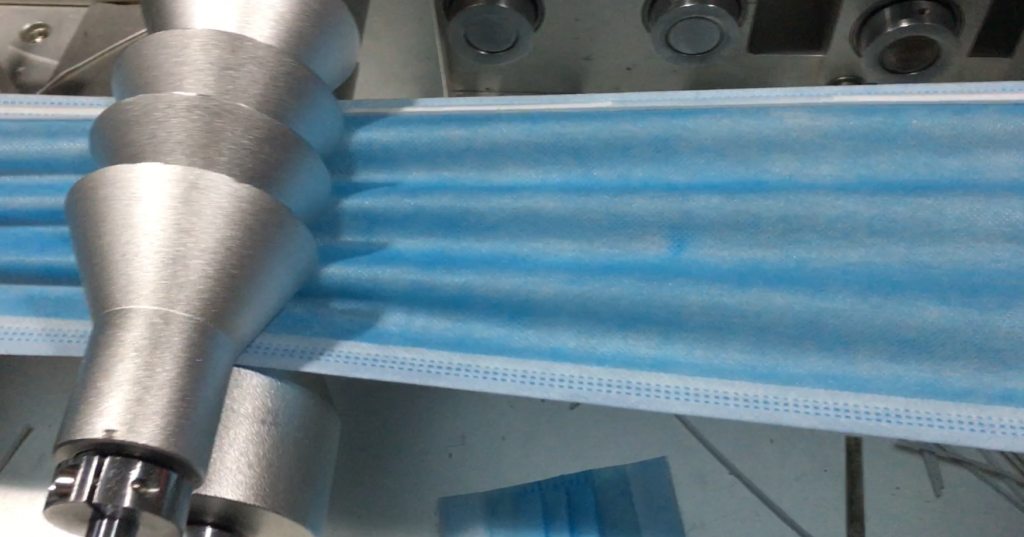

The disposable mask production line adopts a “one drag two” design, that is, a mask forming machine, two ear band welding machines (outer ear bands) are connected through a one-to-two transmission line.

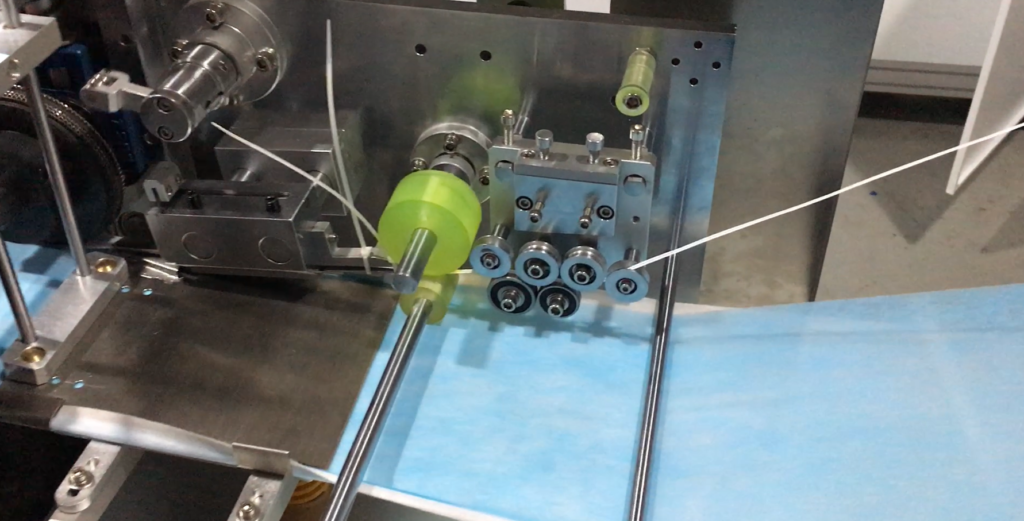

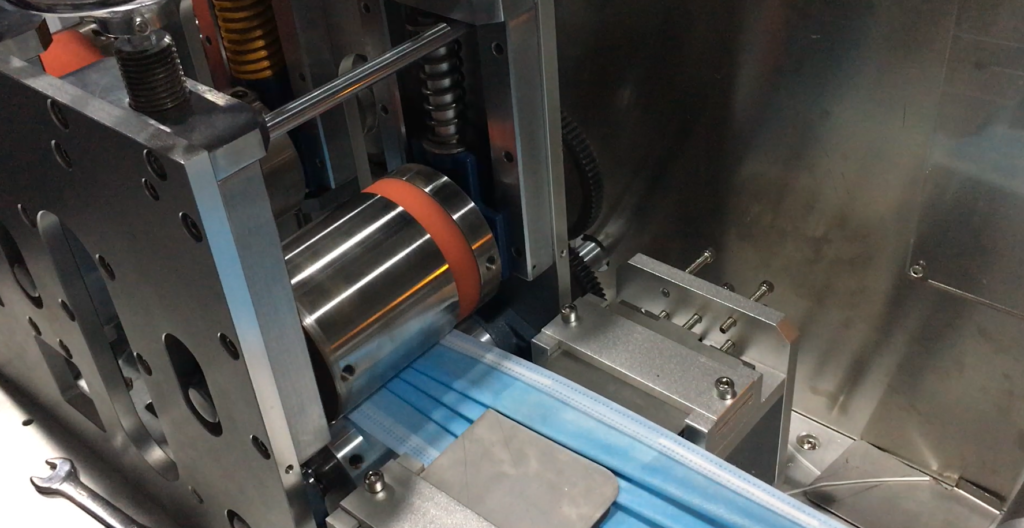

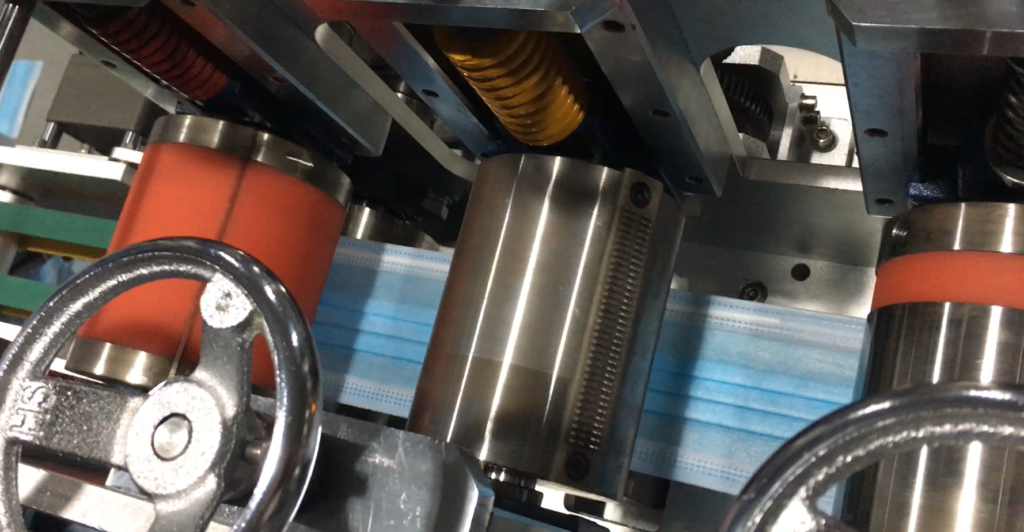

SBM-MM100 can realize the full-automatic production process from coil feeding, folding and pressing, and slitting, ear band feeding, welding, and unloading.

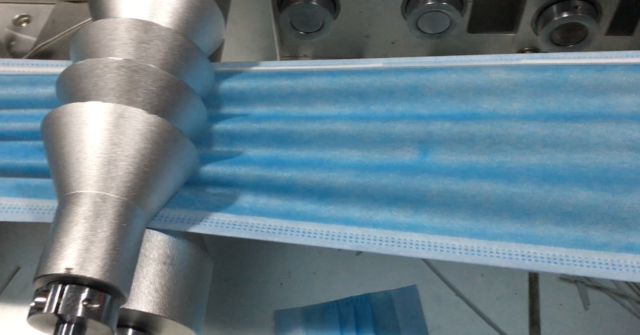

SBM-MM100 can produce disposable masks with a size of 175 * 95mm (adult). The daily production capacity is 150000 (24h).Mask Forming Machine Introduction

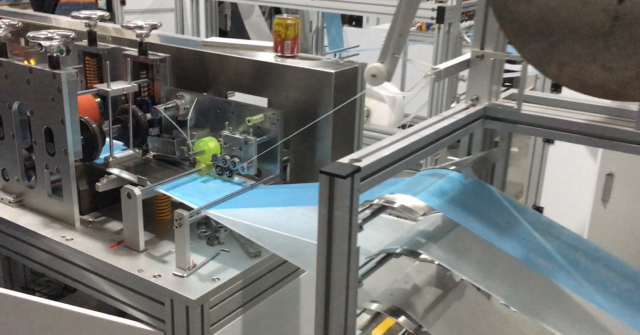

The SBM-MM100“ one-to-two”full-automatic flat mask making machine production line adopts advanced design. It only needs to place the production of raw materials on the feeding rack. After the modulation is completed, the machine can realize automatic production. Only one person needs to operate the packaging, which fully realizes the entire automated production.

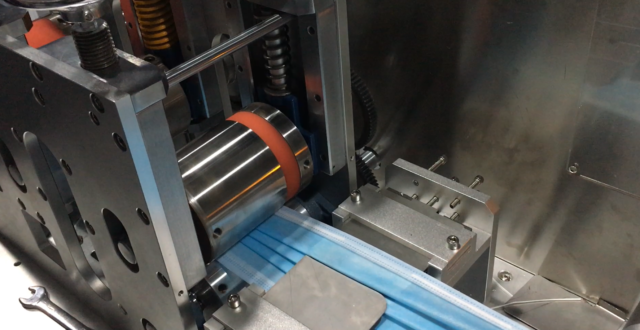

Ultrasonic welding, beautiful style, hygienic and environmental protection.

Operating environment: temperature 10-50 ℃, humidity 5-50%, non-flammable, corrosive gas.Mask forming machine output

The SBM-MM100 medical face mask making Machine’s output is 80-100 pieces per minute, the length of the bridge of the nose bridge is adjustable, and the product size error is ± 1mm.

According to demand, some molds can be replaced to realize a variety of mask sheets.

The-MM100 can manufacture kinds of non-woven face mask: Cloth masks, gauze masks, activated carbon masks, double nose line masks, etc.

Supporting 1-4 layers of non-woven mask sheet production.Ear band welding machine introduction

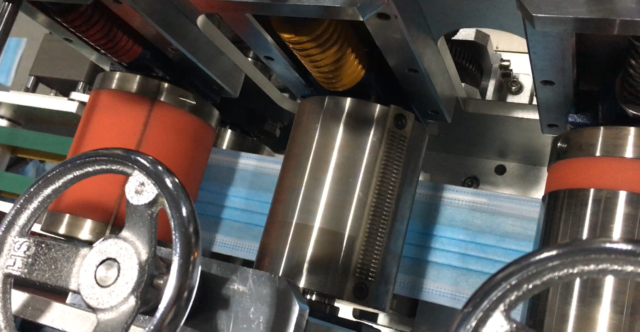

This equipment adopts an ultrasonic welding process. The elastic bands are fused on the inside of the two ends of the mask body.

It is the last processing step of the production of ear band masks. Only one operator needs to place the mask body piece by piece in the mask plate.

To the finished product is completed automatically by the equipment.

This machine adopts servo, step drive, precise transmission, and adjustable speed.

This equipment adopts ultrasonic welding process. The elastic bands are fused on the inside of the two ends of the mask body.

It is the last processing step of the production of earband masks. Only one operator needs to place the mask body piece by piece in the mask plate.

To the finished product is completed automatically by the equipment.Raw materials for manufacturing surgical face mask

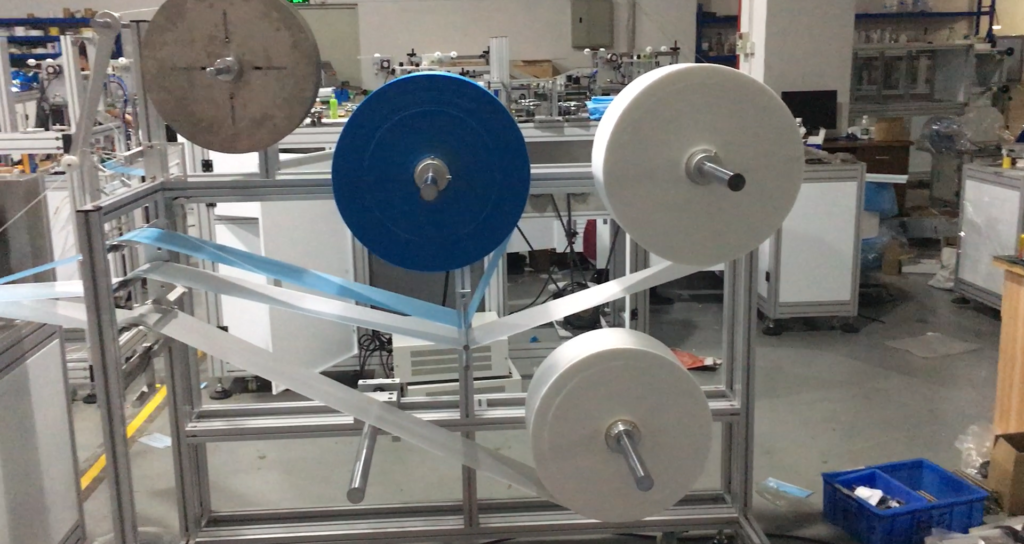

1. Two layers of PP non-woven composite fiber (about 30g)

2. The middle layer is meltblown cloth (about 25g)

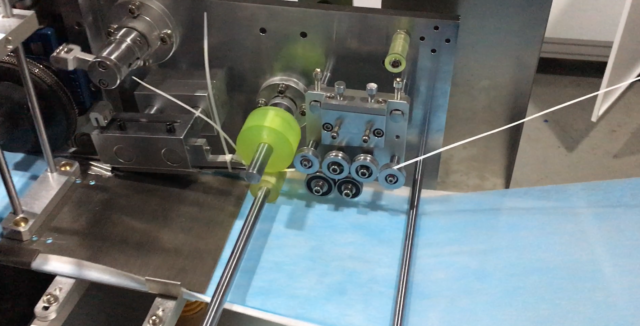

3. Nose bridge strip PP3 mm

4. Earband is round with a diameter of 2.5-3mmSpecifications of production materials

Item Number of hanging shafts Width(mm) Coil outer diameter Inner diameter of barrel Weight Cloth 3 170-200 600 76 Max 30kg Bridge of nose 1 3-7 400 76 Max 30kg Earband 4 3 — — — -

- Techical Info

The following is the standard model technical parameters, special requirements and features can be customized.

Model SBM-MM100 Speed up to 100 pcs per minute Equipment Size 5800mm×3800mm×1700mm Tape Width 48mm, 60mm, 75mm Power consumption 8kw Power supply 220v, AV±5%, 50HZ Workshop standards Class 100,000 dust-free purification Ground load ≥750Kg/㎡ Compressed air 0.5-0.6Mpa Workshop environment Temperature 25℃±5℃, humidity ≤40%, non-flammable,corrosive gas - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

- Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO, THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

- Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the traveling fee on your country) should be on your account and you need paid for the technician USD150 per day. Also you can go to our factory to do training.

- After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

- Comments