- Home

- Products

- Labeling Machine

- Flat surface top labeling machine

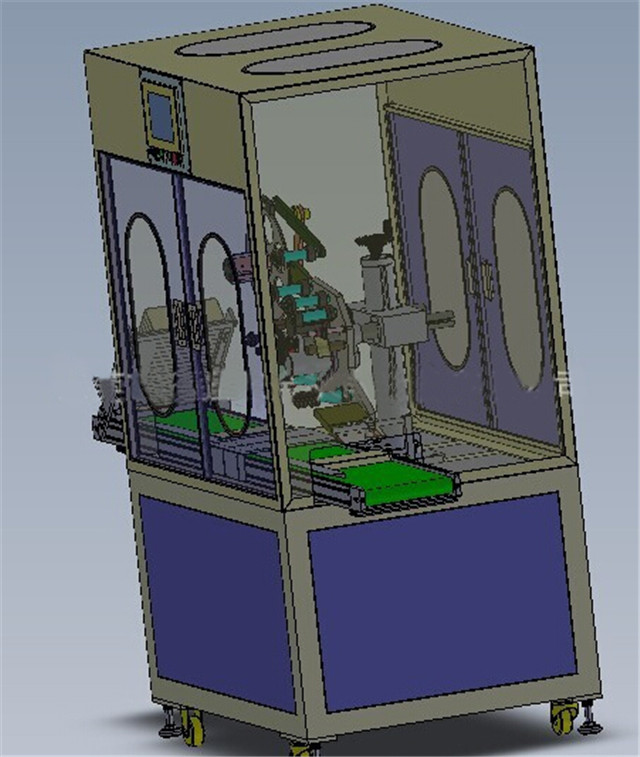

Flat surface top labeling machine

$9550 $8595

flat surface top labelling machines automatic cartons boxes cream jars bottles booklets food flat labeller equipment China reliable labelling machinery.

- General Details

Flat surface top labeling machine automatic cartons boxes cream jars bottles booklets food flat labeler equipment China reliable labeling machinery

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: L/C,T/T

The automatic flat labeling machine is the new generation of packaging equipment. It is special designed based on the automatic labeling machine technology and technical requirements. Can make the adhesive labels stick on the bottle surface smooth and tidy. Labeling process is stable and reliable, and labeling position can reach the ideal requirements.

The automatic flat labeling machine belongs to the electromechanical integration products with reasonable structure. It is used to rolling the adhesive label on the round bottles automatically, when there is lack of bottle, the control system will stop offering the labels, which can avoid the label paper waste effectively, and can adjustment stepless according to the scale of the bottle and the label characteristics.

The Features of the Automatic Flat Labeling Machine

- Suitable for labeling on the flat surface of various products.

- Controlled by the stepping motor, adopts Keyence fiber made in Japan to ensure the labeling accurate and in high quality.

- Dispense special training, the workers can operate and maintenance the machine easily after the simple guidance. The electrical components are all standardization parts, when something is broken, you can purchase them anywhere, the daily maintenance and management are also convenient.

- The whole machine adopts SUS304 stainless steel and T6 aluminum alloy materials, parts and components adopt standardized design, fully comply with GMP environmental requirement.

Operating Principle

When the product is put to the conveyer manually, the conveyer will send the product to the photoelectric sensor area, when the photoelectric sensor get the signal, it will feedback the signal to the system, after receiving the signal, the stepping motor will send out the label, and stick the label on the surface, another photoelectric sensor will limit the sending of the next label on time. When the bottles are sent continuously, the labels are sent out one by one, and label on the surface correctly, after stick the labels on the surface, the brush will smooth the label and ensure the labels stick on the product tightly and smoothly, then the product will be automatic output, the labeling process is finished.

Operation Procedure

- Fix the label roll on the machine according to the graphical representation, adjust the height of each part.

- Check if all the position of the labels are correct.

- Adjust the distance between the two rails, the distance between the brush and the conveyer, make sure the distance is suitable for the product to pass.

- Turn on the power switch, turn on the optoelectronic switch.

- Turn on switch of the motor and label sending device, debug labeling, if there are any abnormal, get rid of them.

- Adjust the labeling position.

- Ensure the test is OK, then operating the machine normally.

- Power off.

Announcements of the label peel board Of The Photoelectricity

- The machine adopts Power Supply of AC 220V. Please make sure the earth wire be connected when working and check if all the parts fixed at the right place before plug in the power supply.

- Please pay attention that if the direction of labels is suitable for the machine. There are two working ways of labeling machine: in at the left and out at the right or in at the right and out at the left. It can be made according to customers’ requirement.

- The guide rings at the bottom of guide wheel should be at the same level, and the above guide ring should be pushed to the edge of label.

- Ensure the labels are pulled smoothly.

- Make sure the electric eye at the right place, or it will be crumpled when labeling.

- Ensure the bottles sending channel is smooth.

- Ensure the routine of labels is correct.

Main Products

Liquid Filling Production Line: Oral Liquid Filling Line; Eyedrop Filling Line; Syrup Filling Line; Cosmetics Filling Line; Medicinal Liquor; Pesticides Filling Line; Special Bottled Filling Line

Table and Capsule Packaging Line: Counting and Packaging Line for Tablet, Capsule, Solid Pills, Cachou etc

Production Line Consists of: Bottle Unscrambler-Bottle Washing-Filling-Capping-Labeling(Shrink Sleeve Labeling Machine)-Boxing Machine

Specialized in various kinds of non-standard automation equipments. - Techical Info

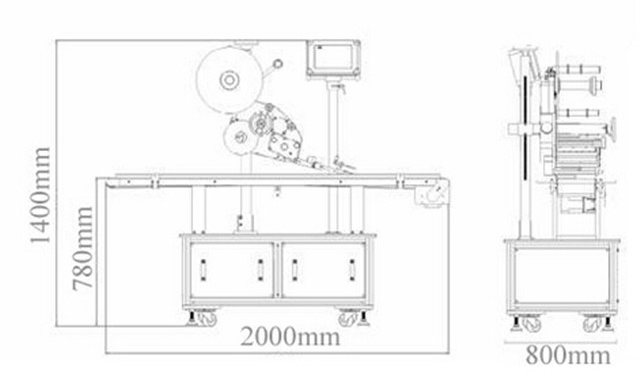

The Main Parameters of the factory price Cartons Automatic Flat Labeling Machine

Model No. SBM-620 Voltage AC110V;50/60HZ Power 180W Speed 0-240 pcs per minute (according to the size of the product and the label) Accuracy ±1mm (according to the surface evenness of the product) Suitable range of the products Length 30mm-300mm, Width 30-260mm Suitable range of the labels Length 20mm-300mm, Width 15mm-120mm Specification of the label roll Outer diameter: 300mm, Inside diameter: 76mm Overall dimensions 2000mm×650mm×1300mm(L×W×H) Weight 250kg Labeling machine electrical configuration list

Name Brand Producing Area Fiber amplifier Keyence Japan Touch screen Weinview Taiwan PLC Delta Taiwan Relay Omron China Stepper motor driver BMW Joint venture Stepper motor BMW Joint venture Reducer motor Zhongda Zhejiang Motor gear box Zhongda Zhejiang Indicator light Apt Shanghai Button Shuangke China Switch power Chuanglian Changzhou Motor speeder Gaoke Zhejiang - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

- Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

- Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account and you need paid for the technician USD50 per day. Also you can go to our factory to do training.

- After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

- Comments