- Home

- Products

- Labeling Machine

- Flat Round bottle Multifunctional Labeling Machine

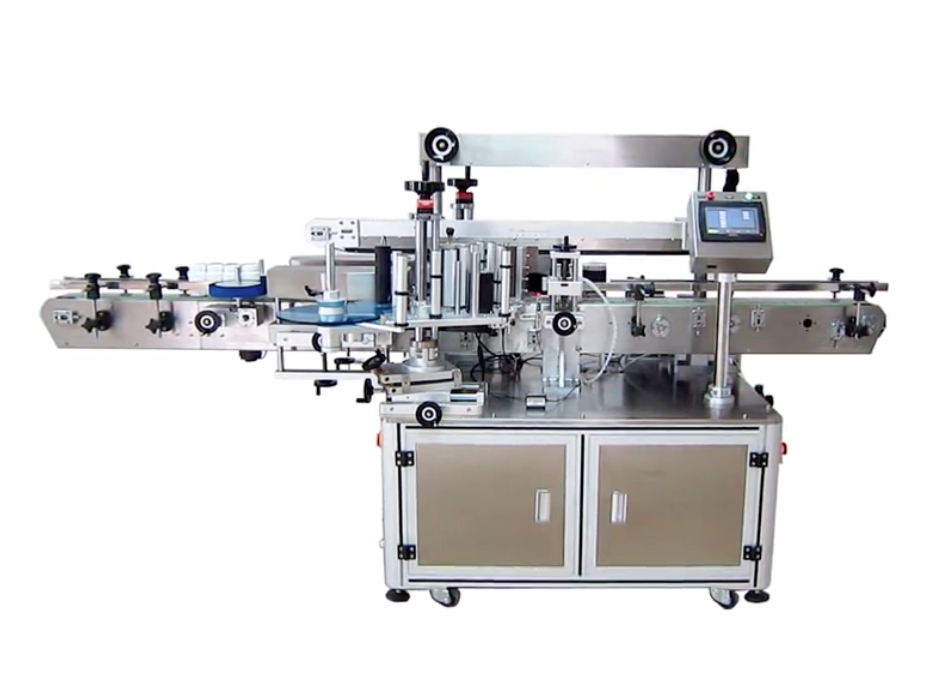

Flat Round bottle Multifunctional Labeling Machine

Fully automatic flat round bottle multifunctional labeling machine Model SBM-LM8200FR

Label feeder of the automatic flat round bottle mult-functional labeling machine

Conveyor system for automatic flat round bottle multi-functional labeler

Labeling system of automatic flat round bottle multfunctional labeler

$13200 $11880

Upgrade Version with high adaptability. Can label one side, two sides, three sides and four sides of square bottle, round bottle with single label.

- General Details

Fully-automatic Flat Round Bottle Multifunctional Labeling Machine SBM-LM8200FR

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: T/T, L/C

Overview

This is our upgraded product, with high adaptability. It can label one side, two sides, three sides and four sides of square bottle, round bottle with single label, such as, health care products, shampoo, shower gel, oil, lubricants, cleaning agents articles, eye drops bottles. It is widely used and can label conical flask.

The machine can packing different objects into labeling machine belt conveyor, by driving a bottle into the bottle conveying institutions, continuous motion by depending on fiber detected after bottle, photoelectric signal transmission to PLC, by PLC output signal processing will lose to the stepping motor, the standard of stepping motor, through the rolling institutions will stick on, tag labeling of objects by labeling machine conveyor belt into the next procedure or containers.

Features

- Powerful, a machine can achieve four kinds of products-sided and double-sided labeling (round bottle, flat bottle, square bottle, shaped bottle). Configure round bottle positioning style cover standard mechanism, enabling single standard round bottle labeling, double standard labeling and spot labeling.

- Uses synchronous bilateral rigid plastic chain guide, automatically guarantee a bottle of neutral, the workers put into bottles and bottles of low demand docking lines, greatly reducing the difficulty docking assembly line worker jobs or be stand-alone production, can also be connected to production line.

- Configuring spring-capping mechanism to ensure smooth product handling and high bottle itself effectively eliminate errors.

- Configure automatic bottle institutions, guided bottle automatically before separate spacing, ensure follow guide bottles, transport and labeling of stability.

- Configure two repeat standard bodies, for the first time to ensure labeling accuracy, quadratic twist roll-covered standard, effectively eliminate air bubbles and ensure the head and tail snapping.

- Intelligent control, automatic photoelectric tracking, with no object no labeling, no label auto-correction and auto-detection function labels, tags and drain to avoid wasting stickers.

- High stability, Panasonic PLC + touch screen + Panasonic Matsushita Electric eye needle + German Leuze label sensor composed of advanced electronic control systems, support equipment 7 × 24-hour operation.

- Equipment is mainly made of stainless steel and high-alloy. GMP compliant design, the overall structure of a solid, beautiful.

- Can be stand-alone production, can also be connected to production lines, automatic product detection, unmanned production.

- Function with downtime, production counting function, power saving features, the production of digital set stop function, parameter setting protection function to facilitate the production and management.

Optional features and components

- Hot coding / marking function;

- Automatic feeding function;

- Automatic rewinding function (combination of product considered);

- Increased labeling devices;

- Circumference circumferential positioning labeling function;

- Other features (according to customer requirements).

- Techical Info

The following is the standard model technical parameters, special requirements and features can be customized.

Labeling speedStepping: 30-160pcs/min (related to the products and labels)

Servo: 50-200pcs/min (related to the products and labels)Model SBM-LM8200FR Label Length 20-200mm Label Width (backing paper width) 20-180 mm Product size (for flat bottle) L (transport direction): 20-250mm *W (transport width direction): 30-90mm*H: 60-310mm Product diameter (for round bottle) 45-90mm Applicable standard roll diameter φ76-φ280mm Labeling accuracy ±1mm The standard speed Stepping: 5-19m/min; Servo: 5-40m/min Conveyor speed 5~18m/min Voltage 220v, 50Hz Power supply 1220W (traction stepper); 1720W (traction servo) Dimension(L×W×H) 3000×1450×1600mm Machine Weight Approx.330kg - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

- Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO, THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

- Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the traveling fee on your country) should be on your account and you need paid for the technician USD50 per day. Also you can go to our factory to do training.

- After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

- Comments