- Home

- Products

- Packing Machine

- Cup forming filling sealing machine

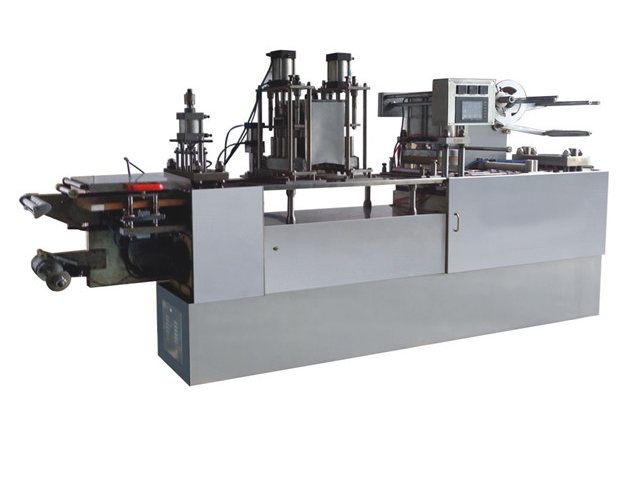

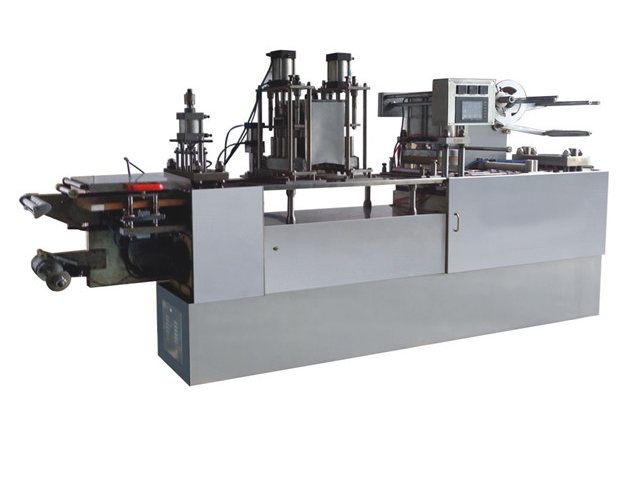

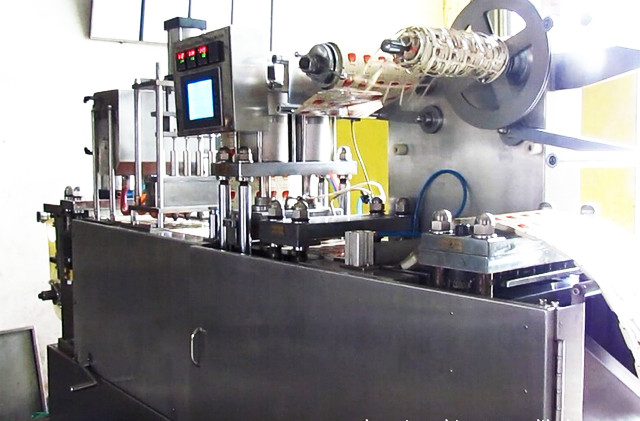

Cup forming filling sealing machine

$38440 $34596

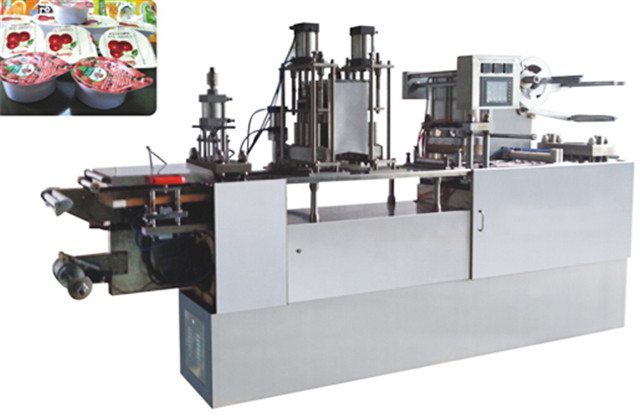

Plastic cup forming filling sealing machine suits for food packaging such as milk, yogurt, chocolate, jam, fruit juice and condiment etc.

SKU: SBM-PM70A Category: Packing Machine

- General Details

Plastic cup forming filling sealing machine for honey, cream, thick sauce etc.

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: L/C,T/T

Plastic cup forming filling sealing machine suits for food packaging such as milk, yogurt, chocolate, jam, fruit juice and condiment etc. It features automatic.

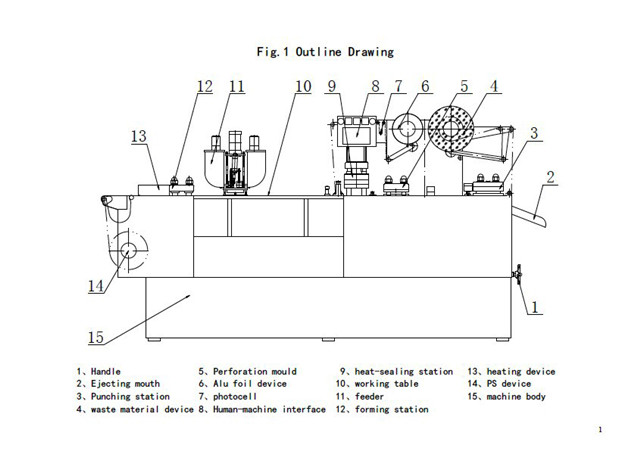

Features of plastic cup forming filling sealing machine

- The machine is specially for food packaging such as chocolate, jam etc. From cup form, fill, seal, cut and product discharge automatically.

- machine-tool track type of casting machine-base, taken these processing like backfire, maturing, high benchmark and without distortion.

- Each box of section processed through professioral, equiipmert,to assure high precision and good exchangeability.

- Forming, sealing, slitting etc.parts are all could be adjust freely on the track with triangle string and flat string, strong applicability. Small oversize, save installation space.

- Reducer adapts parallel-axes bevel wheel, to avoid loose and smooth between chain or strap when it is driving.

- Stroke can be adjust freely, widely used, ease of operation, stable running.

- Adapts up and down net pattern concavo-convex to conjugate,multi-step air cylinder, double-heat sealing. Quality sealing.

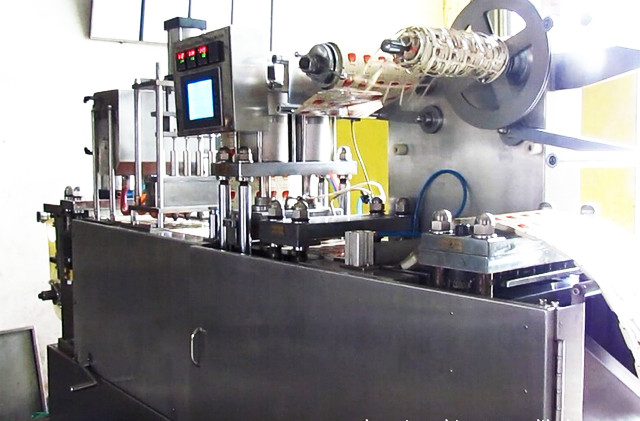

Basic configuration of plastic cup forming filling sealing machine

- PLC adopt Delta from Taiwan

- Touch screen adopt Hitech

- Servo motor adopt Delta from Taiwan

- Electric equipment adopt Schneider

- Filling air cylinder adopt AIRTAC

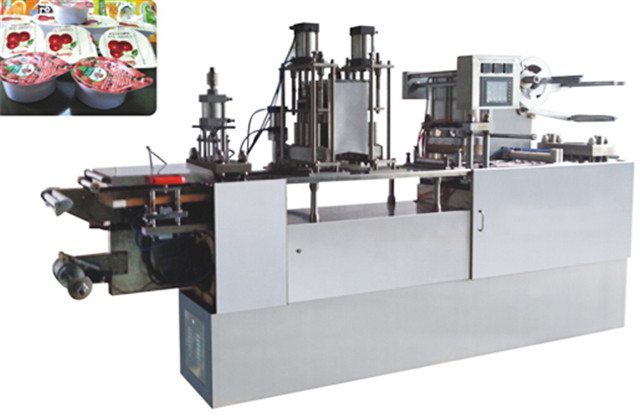

Samples of cups like honey cream from forming filling sealing machine

Packaging for cup forming filling sealing machine

- Techical Info

Model No. SBM-PM70A Cutting Frequency(times/min) 10-30 times/min Max shaping areas and depth(mm) 240X160X26 Air Pressure(kw) 0.4-0.6 Total power 380V/220V 50Hz 6kw Packing Material PVC/PS/PET Pressure(kw) 1.5 Mould Cooling Tap water or Back water Overall Dimensions(mm) 2710X720X1600 weight(kg) 1600 - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

- Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

- Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account and you need paid for the technician USD50 per day. Also you can go to our factory to do training.

- After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

- Comments