- Home

- Products

- Labeling Machine

- Cold glue labeler SBM-LM8021CG

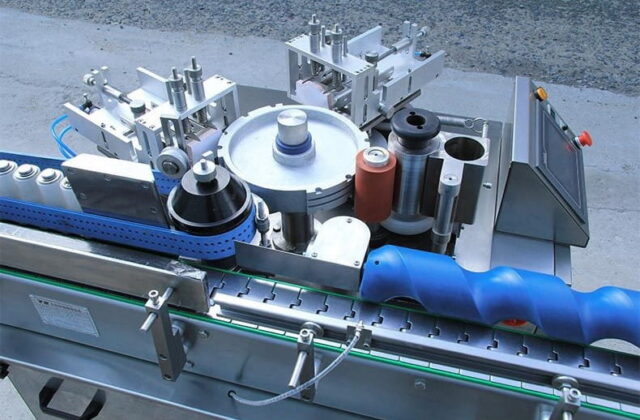

Cold glue labeler SBM-LM8021CG

Automatic cold glue labeler is suitable for labeling of bottles, barrels, cans, cups, hoses, cans and other round bottles in various industries.

- General Details

Cold Glue Labeler | Automatic Cold Glue Labeling Machine SBM-LM8021CG

-

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: T/T, L/C

Overview

Automatic cold glue labeler is suitable for labeling bottles, barrels, cans, cups, hoses, cans, and other round bottles in various industries. The labeling process of paper dividing, gluing, labeling and labeling is completed automatically, which reduces the manual labeling process and improves labeling efficiency. The machine is suitable for round containers in food factories, can factories, liquor factories, general chemical plants, and pharmaceutical enterprises.

This machine can be used alone or in line with other packaging equipment.

Equipment working principle

The machine is designed for round bottle labeling, suitable for all kinds of round bottle labeling. The operation of the machine starts with the sticker bar to stick the resin glue, then the label magazine transfers the label to the sticker bar, rotates and attracts to the vacuum belt through a vacuum, and then sticks the label on the bottle.

Features for automatic cold glue labeling machine

- Glue tank and stainless steel roller processing precision can never leak glue.

- The special rubber roller is processed by several processes, which are not deformed and are resistant to wear and tear. The glue application is even and light, and the amount of glue is saved.

- Use of vacuum suction label, with the belt, the label can be smoothly pasted on the bottle.

- The photoelectric sensor detects the bottle to achieve no bottle without a label.

- Using a frequency converter, the motor running speed can be adjusted freely, and the labeling capacity can be controlled freely.

- Can be operated alone or connected to the production line.

- With a manual adjustment device, easy to adjust the operation.

- By replacing a small number of parts such as the sticker bar and vacuum belt, it can be quickly adjusted and meet various specifications of bottles. And it can eliminate the human adjustment factor to the maximum extent. The adjustment of human factors can be excluded to the maximum extent.

- The whole machine has precise and delicate processing technology, and the basic parts are standard parts, which are convenient for maintenance and repair.

- The whole machine is basically imported configuration to ensure quality, making it more stable, longer use time, and low maintenance rate.

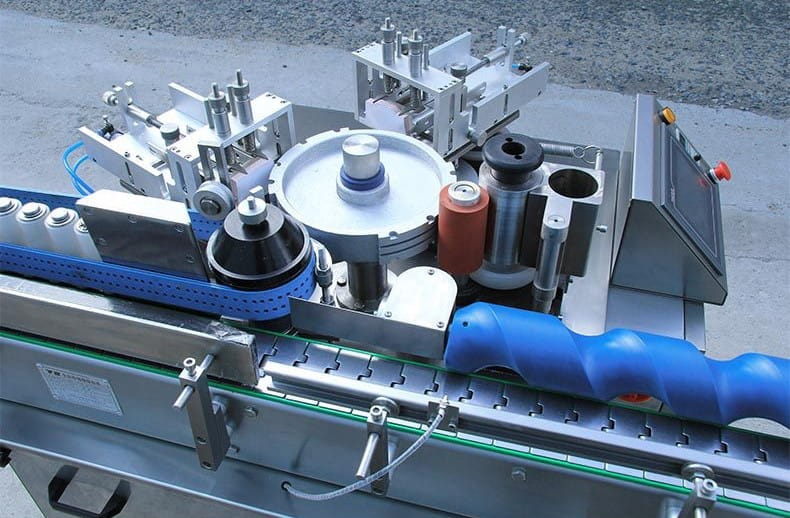

Details for cold glue labeling machine

Operating system. Using touch screen control, the operation is more simple and more convenient, adding metering, timing, and other functions. Maximize the convenience of production needs.

The tank is made of copper, and the appearance adopts a modern galvanizing process. The main roller is made of 304 stainless steel. The combination of copper and stainless steel makes the rolled glue more uniform, thin, and transparent and does not waste glue.

Samples made by cold glue labeling machine

-

- Techical Info

The following is the standard model technical parameters, special requirements and features can be customized.

Model SBM-LM8021CG Labeling Speed 60-100 pcs per min (labeling speed is related to product size) Labeling Accuracy ±1mm (excluding product and label error) Bottle diameter 30-100mm Label Size(LxH) 35-320*30-98mm Power supply Three-phase 380V 50HZ,or Optional Power Approx. 1.5kw Air Consumption(min) 4-6kgs*18liter Dimension(L×W×H) Approx. 3000×1000×1200mm Machine Weight Approx.500kg - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

- Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO, THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

- Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the traveling fee on your country) should be on your account and you need paid for the technician USD150 per day. Also you can go to our factory to do training.

- After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

- Comments