- Home

- Products

- Filling Machine

- Automatic vertical doypack packing machine

Automatic vertical doypack packing machine

$33311 $29980

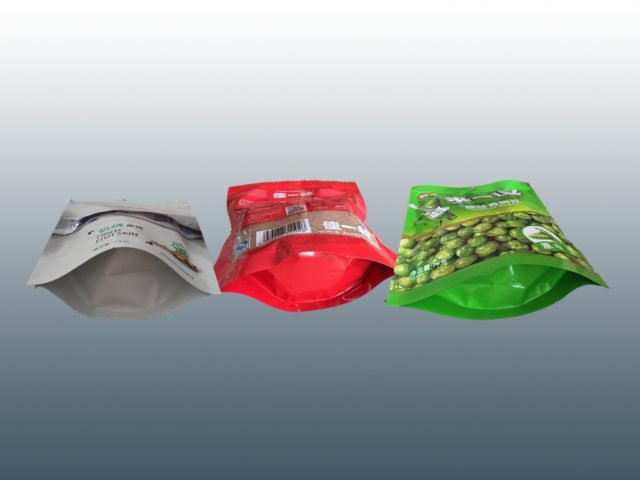

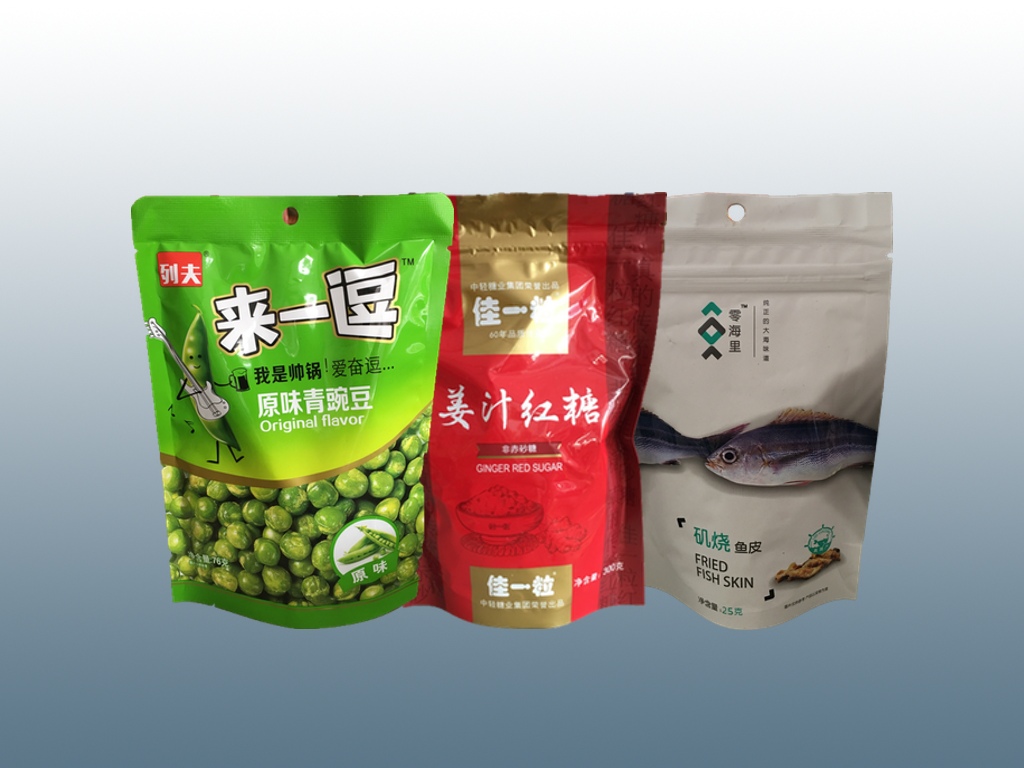

Automatic vertical doypack packing machine is suitable for granule and fluent powder such as sugar, salt, rice, coffee, sesame, forage and so on.

- General Details

Doypack packing machine | Automatic vertical doypack packing machine for granules

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: T/T, L/C

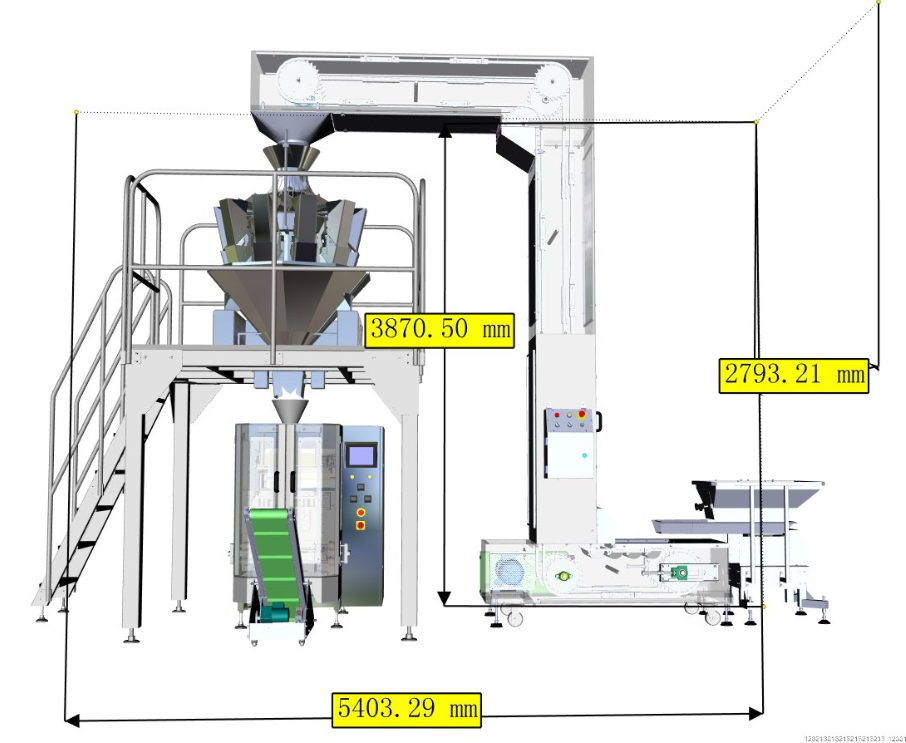

The whole automatic vertical doypack packing machine combined with five parts.

- Packing machine

- Multihead weigher

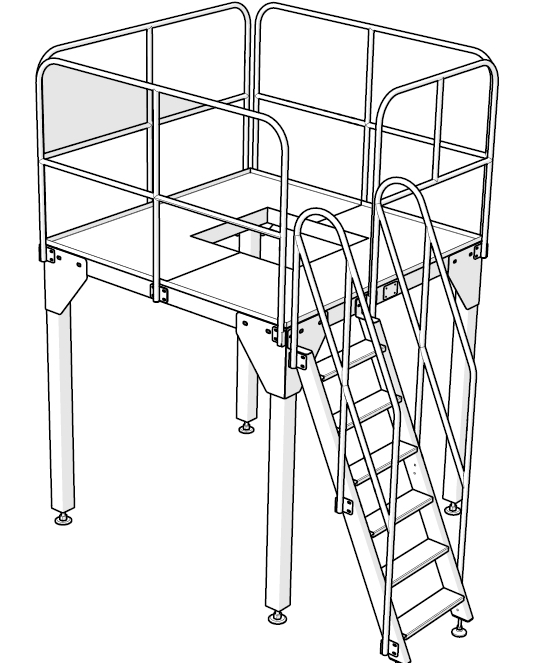

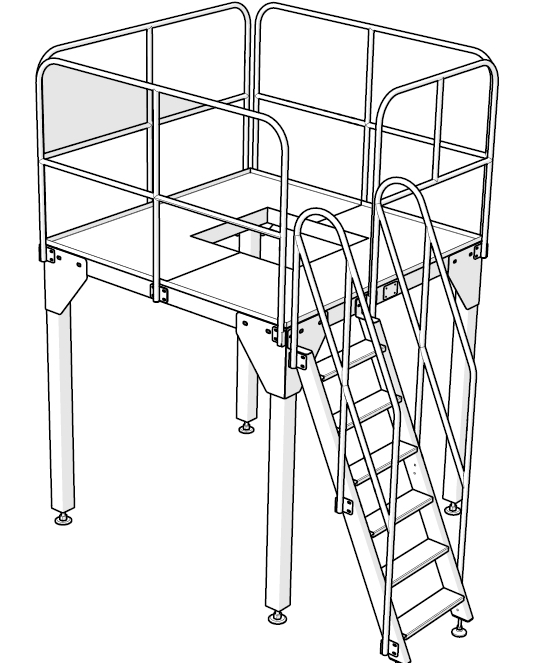

- Working platform

- Z type conveyor with vibration

- Finished product conveyor

Suitable for granule and fluent powder such as sugar, salt, rice, coffee, sesame, forage and so on.

Product features

- With color touch screen and stable and reliable biaxial high PIC control, the output precision of bag making, measuring, filling, sealing, marking, cutting bag for one time.

- Can be connected with production line.

- Controlled by Microprocessor system with LED screen, easy to read and set information.

- Emergency button for safety.

- All are made of 304 stainless steel.

- Easy maintenance and longevity.

Features of model VDM520 packing machine

- This machine has the function of bag making, filling, sealing, printing, punching and counting.

- The servo motor is used to pull the film, and has the function of automatic correction.

- PLC control components are used internationally famous brand products, reliable performance, cross seal, vertical seal with pneumatic, smooth and reliable operation.

- Can complete all packaging processes, measuring, feeding, filling, date printing with measuring device.

- Advanced design ensure that the machine is suitable for different industries. Can be used with a variety of automatic metering equipment.

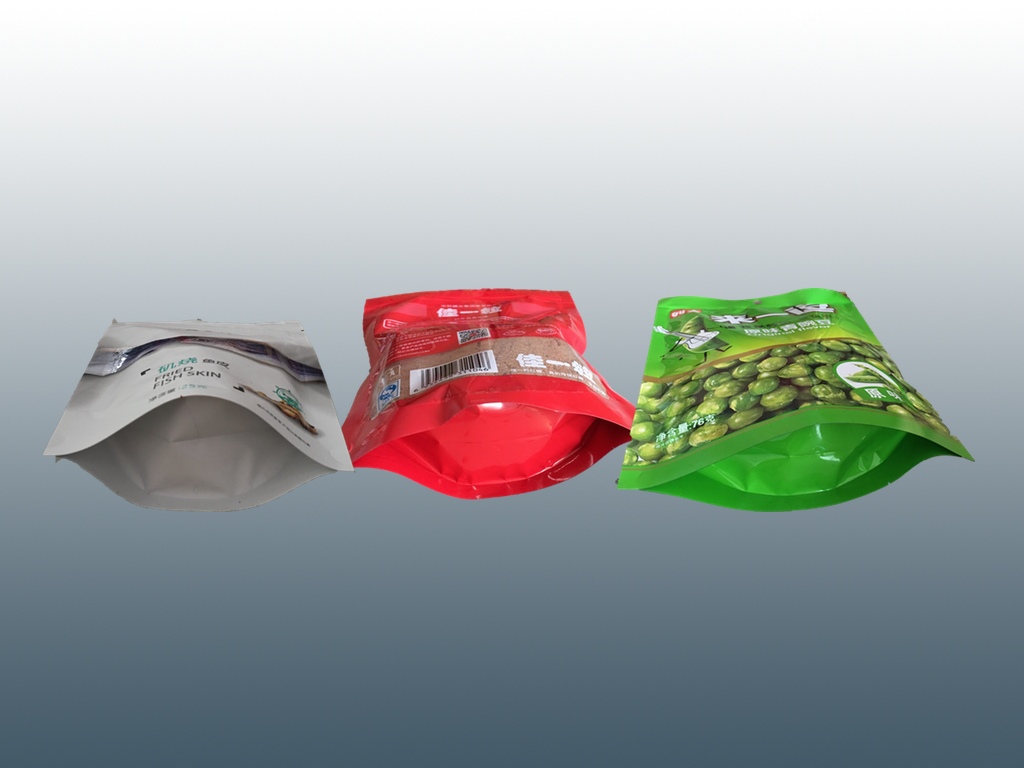

- Can be made stand up pouch with zipper or stand up pouch without zipper.

Electrical standard configuration details for VDM520 packing machine

- Touch screen SIEMENS

- Programmer controlled system Mitsubishi

- Servo motor Mitsubishi

- Servo driver Mitsubishi

- Cylinder for vertical seal AirTAC

- Cylinder for cutting AirTAC

- Electromagnetic valve AirTAC

- Intermediate relay SCHNEIDER

- Power switch SCHNEIDER

- Solid state relay Yanming

- Thermometer control Omron

- Machine material 304 stainless steel

Technical Parameters for model VDM520

- packing speed: 50 bag/min

- Film width: 520mm

- Bag size: (L)100mm-235mm (W) 50mm-190mm, (BW)30-60mm

- Bag type: stand up pouch with zipper or stand up pouch without zipper

- Film thickness: 0.04-0.09mm

- Air consumption: 0.8Mps 0.7m3/min

- Power source: 3.0kw, 220v, 50HZ/60HZ

- Dimension: L1120mm*W1480mm*H1750mm

- Weight: 630kg

10 heads multihead weigher

- High precision data-type weighing sensor realizes precision weighing.

- Microcomputer control system with double vibration feeding and imported instrument, advanced technology and simple operation.

- Stainless steel sealed machine body; corrosion resistance and dust resistance.

- The measuring hopper can be disassembled rapidly; and it’s convenient in cleaning and maintenance.

- It can make different combination to enlarge according to customer’s requirements.

- With strong compatibility, it’s easy to supported with other packing device

Technical Parameters for 10 heads multihead weigher

- Weighing range: 10-1000g

- Weighing accuracy: 0.5-2.0g

- Weighing speed: Max. 110 bpm

- Hopper size:1.6L

- Controller: 7’’ touch screen

- Drive mode: stepper motor

- Structure: 304 stainless steel

- Power supply: AC 110/220, 50/60 Hz

- Power: 1kw

- Weight: 389kg

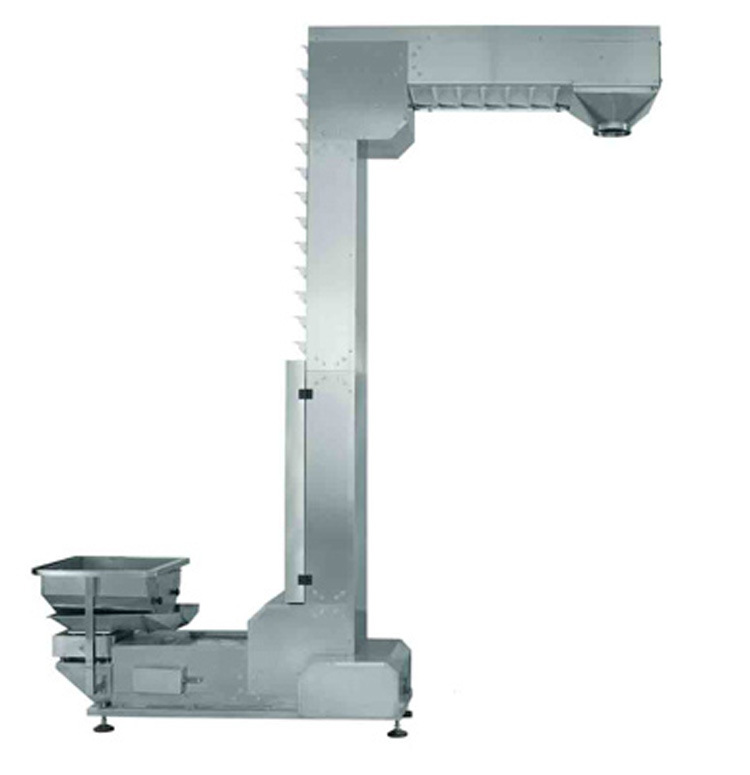

Z type conveyor with vibration

The lifting machine is suitable for grain, food, feed, chemical industry, etc.. The hoist is driven by a chain to drive the hopper to be lifted, and the utility model is used for vertically conveying particles and small pieces of material, and has the advantages of large lifting capacity and high lifting degree.

Advantages of YC-TK9-Z new version material conveyor

- All gear bold, stable operation and low noise.

- The chain of bold, more stable operation.

- The conveyor hopper for the button type, will not drop material and bucket.

- Full closed, clean health.

Technical Parameters for Z type conveyor

- Model: YC-TK9 Z

- Lifting height: 3m

- Hoisting speed: 0-17m/ points

- Lifting capacity: 6 cubic meters / hour

- Total power: 550W

- Voltage: 220/380V

- Specifications: The material can be made according to customer requirements, carbon steel or stainless steel, and material contact part for food grade plastic

Technical Parameters for finished product conveyor

- Lifting height: 0.6m-0.8m

- Lifting capacity: 1 cmb/hour

- Transfer rate: 30m\minute

- Outline dimension: 2110 x 340 x 500mm

- Voltage: 220V/45W

- Techical Info

Model No. SBM-VDM520 Capacity 50 bags/min, depends on wrapping and supplies Accuracy ≤±0.5-1% Bag size (L)100-235mm (W)50-190mm Film width 520mm Bag type With film packaging materials, automatic making bag and sealing Filling range 150-500ml, or 10g-1000g Film thickness 0.06-0.08mm Package material Thermal composite material, like BOPP/CPP, PET/AL/PE etc. Air consumption 0.8Mpa, 0.5m3/min Air compressor Not less than 1 cbm Total powder Z type conveyor with vibration (0.55kw) + ten heads weigher (1kw) +packing machine (3kw) +finished product conveyor (0.045kw) =4.6kw Voltage Two-phase three-wire 220V,50Hz Total height 3.944m - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

- Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

- Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the traveling fee on your country) should be on your account and you need paid for the technician USD50 per day. Also you can go to our factory to do training.

- After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

- Comments