- Home

- Products

- Packing Machine

- Automatic Stand-up Zipper Pouch Packaging Machine

Automatic Stand-up Zipper Pouch Packaging Machine

sbm-pm210s-300s-details-of-coffee-powder-milk-granules-doypack-packaging-machine

Details of coffee powder milk granules doypack packaging machine

Details of coffee powder milk granules doypack packaging machine

sbm-pm210s-300s-the-front-of-coffee-powder-milk-granules-doypack-packing-machine

The front of coffee powder milk granules doypack packing machine

The front of coffee powder milk granules doypack packing machine

sbm-pm210s-300s-the-whole-view-of-coffee-powder-milk-granules-doypack-packaging-machinery

The whole view of coffee powder milk granules doypack packaging machinery

The whole view of coffee powder milk granules doypack packaging machinery

$25541 $22987

Rotary Weighing & Packaging Line for Solid (or Grain) with weigher and Z-shaped Conveyor, is suitable for packing all kinds of powder grains and solids.

SKU: SBM-PM210S-300S Category: Packing Machine

- General Details

Automatic Stand-up Zipper Pouch Packaging Machine/Coffee powder milk granules doy pack packing machine

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: T/T, L/C

Application

SBM-PM200/300S Rotary Weighing & Packaging Line for Solid (or Grain) with weigher and Z-shaped Conveyor, is suitable for packing all kinds of powder grains and solids, such as candy, nuts, raisins, peanuts,melon seeds, potato chips, chocolate, biscuits and so on.

Function and characteristics of rotary weighing & packaging line for solid

- Easy to operate,adopt advanced PLC from Germany Siemens, mate with touch screen and electric control system,the man-machine interface is friendly.

- Frequency conversion adjusts the speed: this machine uses frequency conversion equipment,can be adjusted within the range according to the needs of reality in production.

- Automatic checking: no pouch or pouch open error, no fill, no seal. the bag can be used again,avoid wasting packing materials and raw materials.

- Safety device: Machine stop at abnormal air pressure, heater disconnection alarm.

- Horizontal conveyor style to giving bag: it can put on more bags on the bag storage and have a low requirement about the quality of bags.

- Use the plastic bearing, don’t need put on oil, less pollution. Use no oil vacuum pump, avoid polluting the environment in the production.huff,clamp the meatus of bag when put the windpipe into it, then huff to open up the bag fully to bottom in oder to avoid the material overflow from the bag if it is not opend fully.

- The packing materials loss low, what this machine is used the preformed bag,the bag pattern is perfect and has a high quality of the sealing part, this improved the product specification.

- Product or packing bag contact parts adopt stainless steel or other materials which accord with the food hygienic requirements, guarantee hygiene and security of the food With different feeders changed to pack solid, liquid, thick liquid ,powder and so on.

- The packing bag suits in extensive range, suit for multi-layer compound, monolayer PE , PP and so on Preformed bag made by film and paper.

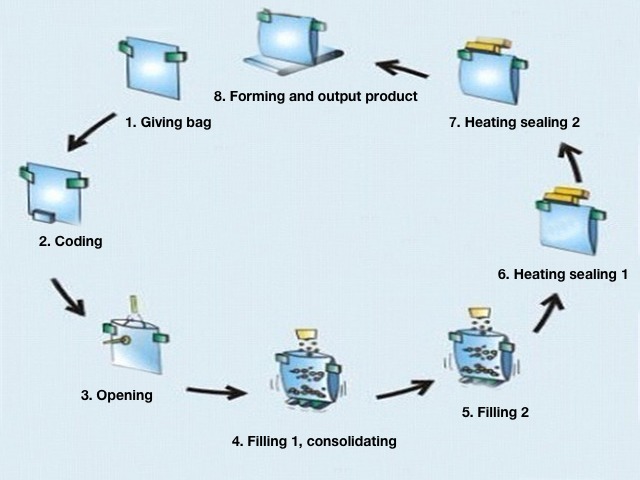

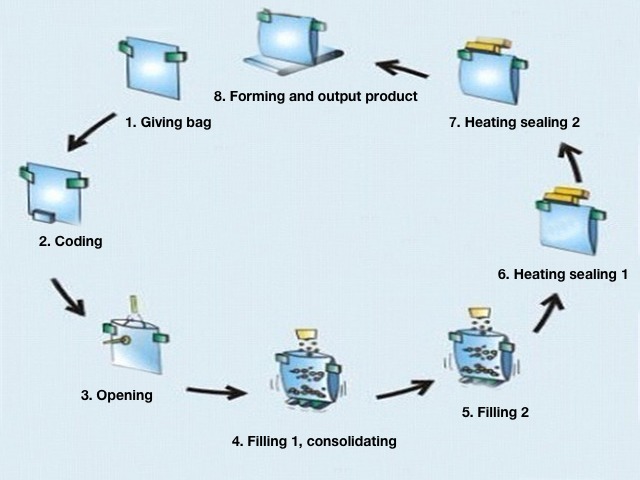

Product process of rotary weighing & packaging line for solid

1.Giving bag; 2. Coding date; 3. Opening bag; 4.Filling and vibrating; 5.Heat sealing; 6.Forming and outputting product

Main parts of rotary weighing & packaging line for solid

Item Model No. Brand PLC S7-200 Germany SIEMENS Touch screen TPC7062KS KUNLUN TONGTAI Frequency converter G110 Germany SIEMENS Vacuum pump KRX5P-V03 Japan ORION Printer NY-803 Zhangzhou NANYUN Vacuum filter AFC3000 ShangHai STNC Digital pressure switch AW30-02B-X465A Japan SMC Valve SY5120-5G-01 Japan SMC Valve VP342R-5GR-02A Japan SMC Valve VQ21A1-5G-C8-F Japan SMC - Techical Info

Model No. SBM-PM210S SBM-PM230S SBM-PM300S Pouch Type Flat bag, 3-side sealing bag, 4-side sealing bag, zipper bag, standup bag etc. Pouch Material Laminated film, PP, PE etc. Pouch size W:80-210mm L:150-300mm W:80-230mm L:150-300mm W:150-300mm L:150-300mm Packing weight 5-1500g Packing Speed 20-55 Bags/Min (depends on the packing material and filling weight) 30-55 Bags/Min (depends on the packing material and filling weight) 20-45Bags/Min (depends on the packing material and filling weight) Packing Accuracy ≤±1% Power and volt 3.5KW,AC380V,50Hz 3.5KW,AC380V,50Hz 4.2KW,AC380V,50Hz Air Consumption 0.3m3/min 0.3m3/min/ 0.3m3/min Overall Dimensions (L*W*H)(mm) 4200*2000*3700 4340*2000*3700 4600*2200*3700 - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

- Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

- Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account and you need paid for the technician USD50 per day. Also you can go to our factory to do training.

- After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

- Comments