- Home

- Products

- Labeling Machine

- Automatic Rotary Round Bottle Labeler

Automatic Rotary Round Bottle Labeler

$13978 $12580

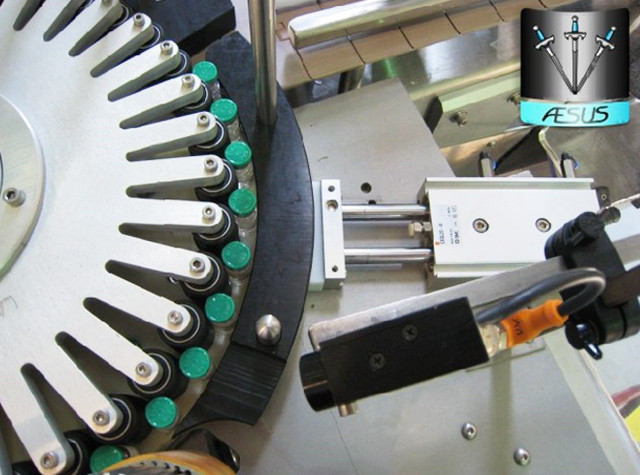

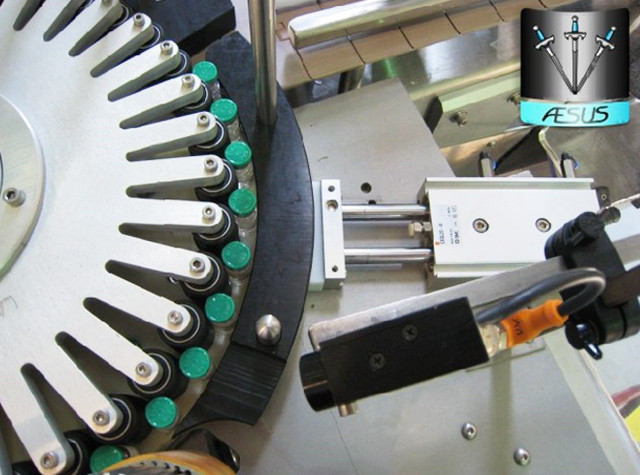

SBM-RL660 is available for any kind of erective plastic bottle and glasses labeling such as water bottle, yoghurt, wine bottle, seasoning, cleanser, small round bottle, ampoule, nail polish, lipstick, mascara, lip gloss, battery etc.

- General Details

Automatic Rotary Round Bottle Labeler

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: L/C,T/T

SBM-RL660 is available for any kind of erective plastic bottle and glasses labeling such as water bottle, yoghurt, wine bottle, seasoning, cleanser, small round bottle, ampoule, nail polish, lipstick, mascara, lip gloss, battery etc. Different kind of label like transparent label, anti-forgery label and barcode label are all applicable to automatic rotary round bottle labeler.

Features of the Automatic Rotary Round Bottle Labeling machine

- Be pioneer of the industry to adopt PLC Human-computer control system with touch panel, and is easy to read and realize.

- Adopt high-class servo motor for better labeling efficiency.

- Provided with 60 sets of memory to save parameters from different production line and is convenient to make adjustment between various productions.

- Create humanized operation design like color touch panel.

- Active detection system gives the alarm and machine stops working when out of carbon fiber tape.

- The design of linked operation system will adjust label applicator and conveyor belt immediately to improve accuracy of labeling and stability of bottle delivery.

- Choose the perfect and proper bottle separating or delivering devices according to labeling speed and bottle size.

- Power spacer separates containers into fixed space.

- Professional design and solid structure such as controlled by frequency conversion servo motor, Europe-made speed reducer and conveyor belt boosted by alternating current frequency conversion servo motor to reach high quality manufacture.

- All the machine’s design and spare parts are standardized and can be freely collocated to reach requirement and best efficacy.

- Self-correcting system makes sure bottles stand at the right position.

- Electronic automatic label-counting system informs you of the labeling progress.

- The labeling height and angle can be easily adjusted by the product.

- Locating devices keep delivering product and detect the right labeling position.

- Wrap station makes labels adhere perfectly to round/flat/square bottles. (only need few modification to the labeler)

- Smart detection system for missing labeling to guarantee labeling quality.

- Conveyor belt and labeling speed can be adjusted to meet requirement.

- Easy to operate with auxiliary microprocessor CPU system.

- Control labeling progress by LED screen and electronic technical system.

- Label sensor doesn’t need to be readjusted as replacing labels and products.

- The fixed base with moving wheels greatly improve its flexibility for movement

- Our MCC conveyor belt complies with Food Sanitation Standards.

- Made of stainless steel SUS#304 and aluminum alloy for easy maintenance and longevity and complies with GMP regulation .

Samples for Automatic Rotary Round Bottle Labeling machine

- Techical Info

Model No. SBM-RL660 Labeling capacity(pcs/min) 40-150 pcs/min Labeling accuracy(mm) ±1.0mm Label size (L)20-280mm (H)30-140mm Material size Φ40-Φ100mm (H)40-300mm Roll inside(mm) Φ76mm Roll outside diameter(mm) Φ350mm Machine size (mm) (L)2000*(W)850*(H)1450(mm) Power supply AC220V 50Hz/60Hz 1500W - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

- Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

- Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account and you need paid for the technician USD50 per day. Also you can go to our factory to do training.

- After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

- Comments