- Home

- Products

- Sealing Machine

- Automatic induction sealer

Automatic induction sealer

$1875 $1688

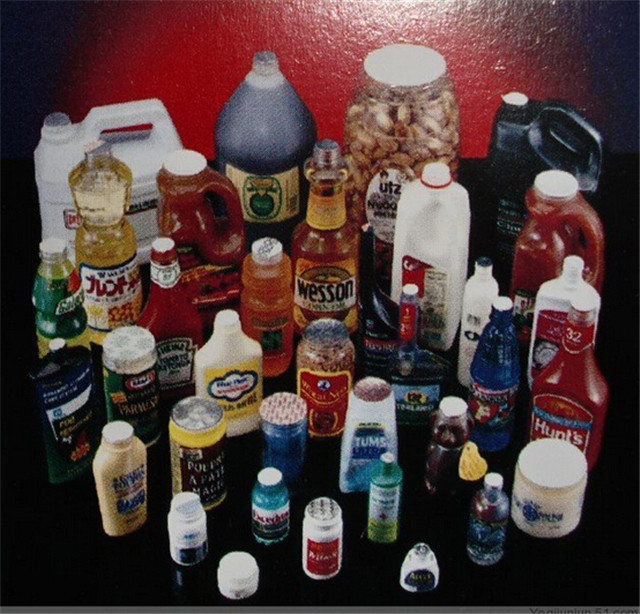

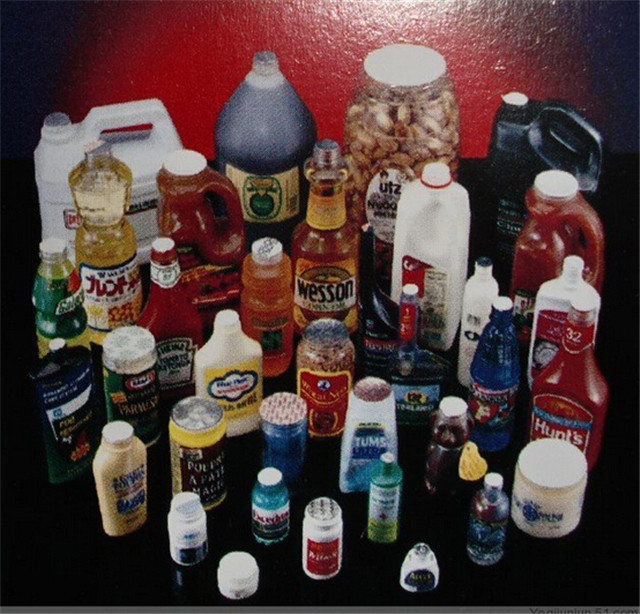

Induction sealing machine meets all the performance criteria of the food, beverage, cosmetic, oil and chemical industries.

- General Details

Automatic induction sealer

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: L/C,T/T

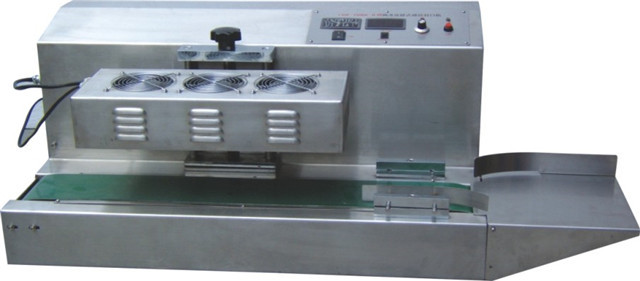

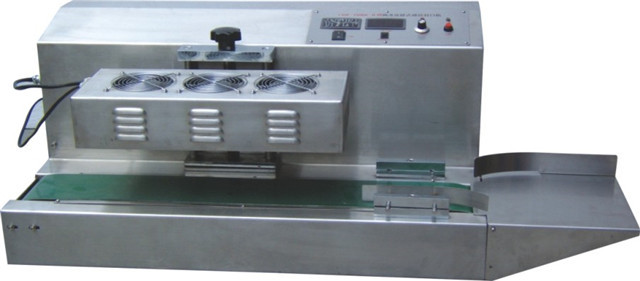

The automatic induction sealer enable to non-metallic bottles with aluminium foil in moving under the electromagnetic induction device which will produce instant high heat to melt aluminium foil and make it adhesive to bung hole, and then bottles are sealed. The bottle material can be PE, PP, PET, PS, ABS, glass, ceramics and so on. The aluminum foil induction sealing machine meets all the performance criteria of the food, beverage, cosmetic, oil and chemical industries.

Working Principle

The induction sealing technology which was thought to be very mysterious is actually not very hard to understand. Induction power passes the electric energy to the aluminium foil inside of the cap by induction current. The electric energy translates into thermal energy which melts the polymer pasted on aluminium foil.So induction sealing is an untouched heat treatment process. The sealing is after filling and capping work.The FDA considers the induction sealing can effectively keep the trace of opening.

Components of Induction Sealing Machine

The continuous induction sealing machine is composed of 3 parts: induction power,

induction sealing head and conveyor.

Power is running in high frequency as a generator, providing electric current for the induction sealing head.There’s induction coil inside the induction sealing head and a stable magnetic field will from around the sealing head after turning on the machine.

The conveyor carries the bottles to the magnetic field under the sealing head to form a whirlpool on the aluminium foil which translates the electric energy to heat.

Wad

Wad’s are innerseal materials, which are available in different variations to meet almost any standard or customized packaging need. Modifications can be made to suit the types of container, closure and product. There is almost no limit to the size of container, the Wad’s can seal. The typical induction innerseal begins with a multi-laminate liner inside a closure. It is made up of following layers:

- A layer of pulp board

- A layer of wax

- Aluminium foil

- A layer of polymer (Heat sealable film)

- Techical Info

Model No. SBM-SM1500A SBM-SM2000A Voltage AC220V±10% 50Hz Power 1500W 1800W Working Current ≤8 (A) ≤9 (A) Control Circuit transistor control circuit Sealing Diameter 20-50mm 50-130mm Bottle Height 40-400mm 40-300mm Working Mode Continuous work Cooling Method Fan cooling Machine Type Desktop Mode Machine Body Cold roller sheet/ Stainless Steel+ Aluminum Cold roller sheet Sealing Speed 0-10m/min 0-12m/min External Dimension

(L*W*H)1150×480×400 1150*560*400 Net Weight 38KG 42KG - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

- Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

- Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account and you need paid for the technician USD50 per day. Also you can go to our factory to do training.

- After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

- Comments