- Home

- Products

- Labeling Machine

- Automatic Hot Melt Glue Labeler

Automatic Hot Melt Glue Labeler

$76545 $68890

Suitable for different industries for mineral water , soft drink, seasoning, wine cosmetics and others. It can stick many kinds of shape of PET bottle, tin can and other containers.

- General Details

Hot Melt Glue Labeler | Automatic Linear Hot Melt Glue Labeling Machine Model SBM-HMGL2000

-

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: T/T, L/C

Overview

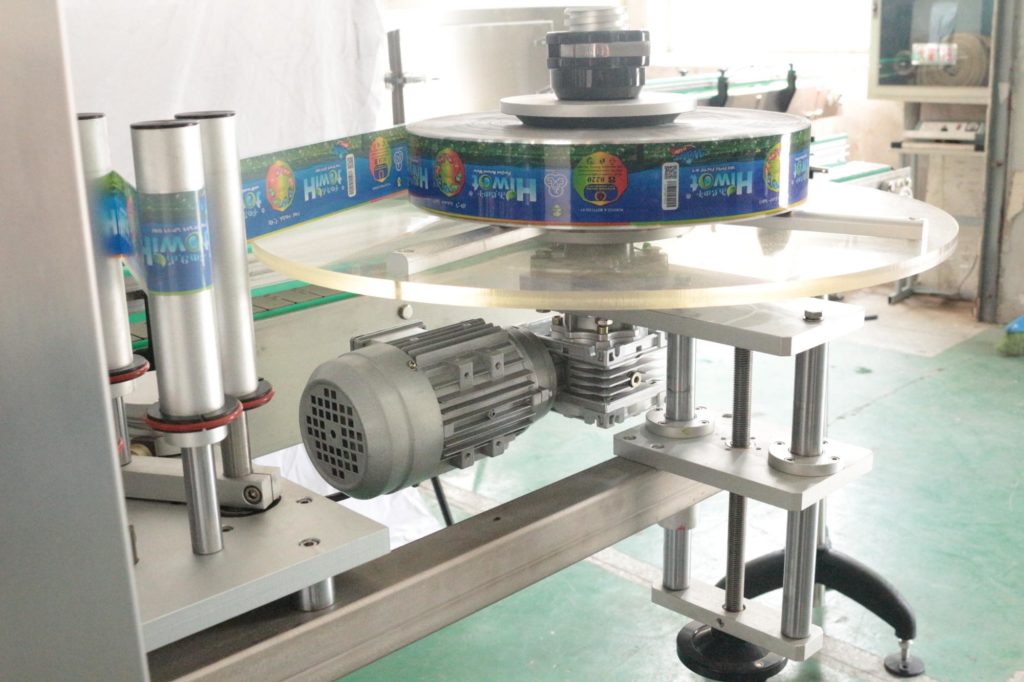

This hot melt glue labeler is widely suitable for different material of container and label.The label cost is comparatively lower, it can meet the requirements of those users who have diverse kinds of the containers. It is the most economical model in cost to make mass production and integrated operating. The equipment has massively used modularization design concept to make it easy and simple for users to change the bottles. Whether from the replacement of star wheel, guide plate or manual speed adjustment to automatic speed control, for example changing the label is only needed to change the program, the products concept of that the equipment is designed for users is embodied in everywhere.

This equipment adopts the current labeling machine type, the most advanced, the most precise method for the volume label of OPP and other plastic material as base material, through the automatic correction instrument and various kinds of high precision photoelectric sensing elements to control the label location precision, adopt scientific institutions to complete automatic cutting and automatic send logo, and will be in the form of roller coating label solid, reliable and accurate paste on the packing materials.

The advantages of fully automatic rotary sensor servo positioning hot melt roll fed labeling machine

- The roller coating way more save than spraying way on the usage of glue, glue it cloth glue more uniform, more plentiful, so that the joint more smooth, more strong.

- In the aspect of control system using more advanced than other coating way mechanical and inductance double security agencies, labeling effect is more reliable, reduces the label attrition rate.

- The device is particularly suitable for PET plastic bottles and other hard surface bonding packing materials, also suitable for super long, circular plastic mark paste.

- Advanced labeling method determines the overall structure of the superior design, making the equipment from the production of precision, production efficiency and service life are the corresponding, is the most excellent models of similar products at home and abroad is alternative set of label and the best choice of the spray glue labeling machine, the effective ways to realize environmental protection, high efficiency, energy saving.

Features of hot melt glue labeler

- Strict requirements and meticulous assembly, which make the machine running stability.

- The speed flexible, can be adjusted to 36,000 bottles per hour.

- Rotary design, compact structure, beautiful shape, and material specification- anti-acid/alkali stainless steel wrapped.

- It is simple and quick to change configuration Component and different containers and labels.

- It is adopted automatic helicoid conveying bottle device which has large operation space. The container can complete the adjustment of multi gesture at one time. The device of adjusting brush plate is very simple.

- Centralized lubrication system allows the operation of machinery lubrication components more simple, more normal, more to ensure that the machine life. The machine is simple and convenient maintenance.

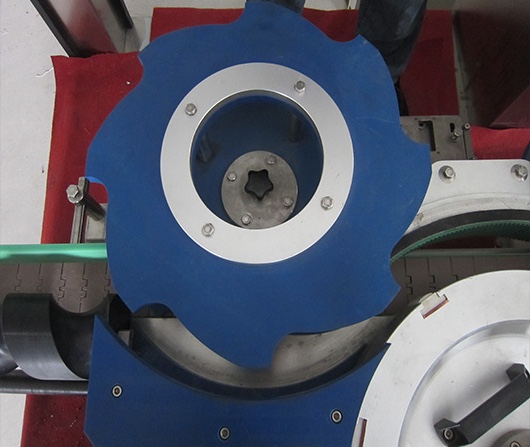

Bottle feeding star wheel adopt ultra-high molecular materials processing , durable for positioning the bottle to make sure bottle goes into accurate labeling station.

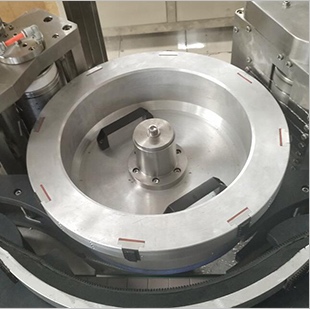

Labeling rotating drum use high grade material, cut label adsorbed on it for sticking glue, and then paste label on bottle.

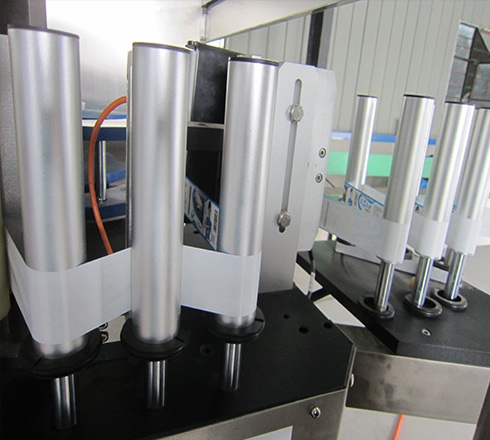

Coating system cut label rolling glue here.

Scope of application of hot melt glue labeler

Hot melt glue labeling machine suits for different industries for mineral water , soft drink, seasoning, wine cosmetics and others. It can stick many kinds of shape of PET bottle, such as round bottles, square bottles or others.

-

- Techical Info

The following is the standard model technical parameters, special requirements and features can be customized.

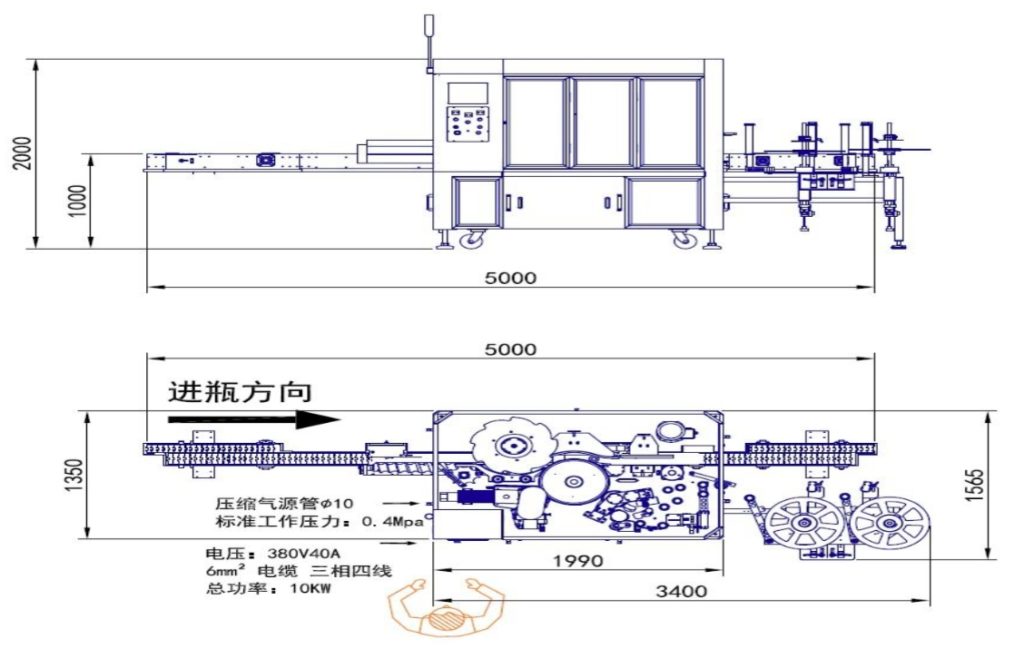

Model SBM-HMGL2000 Labeling Speed up to 24000 bottles per hour Labeling Accuracy ±0.5mm Bottle Type plastic bottle, glass bottle, metal can Bottle Size Out diameterφ40mm~φ120mm,height30mm~200mm(can be customized) Label Material OPP/ Pearl film/Composite paper Label Size (bottom)Height40~200mm,Length120~376mm Label Thickness 0.04-0.05mm Power supply AC 220v/50Hz AC 380V/50Hz 3Ph,or Optional Power 10kw Air Consumption 0.4Mpa Dimension(L×W×H) Approx 5000×1600×2000mm(including the length of conveyor belt) Machine Weight Approx.2000kg - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

- Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO, THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

- Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the traveling fee on your country) should be on your account and you need paid for the technician USD50 per day. Also you can go to our factory to do training.

- After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

- Comments