- Home

- Products

- Packing Machine

- Automatic Hot Melt Glue Carton Packing Machine

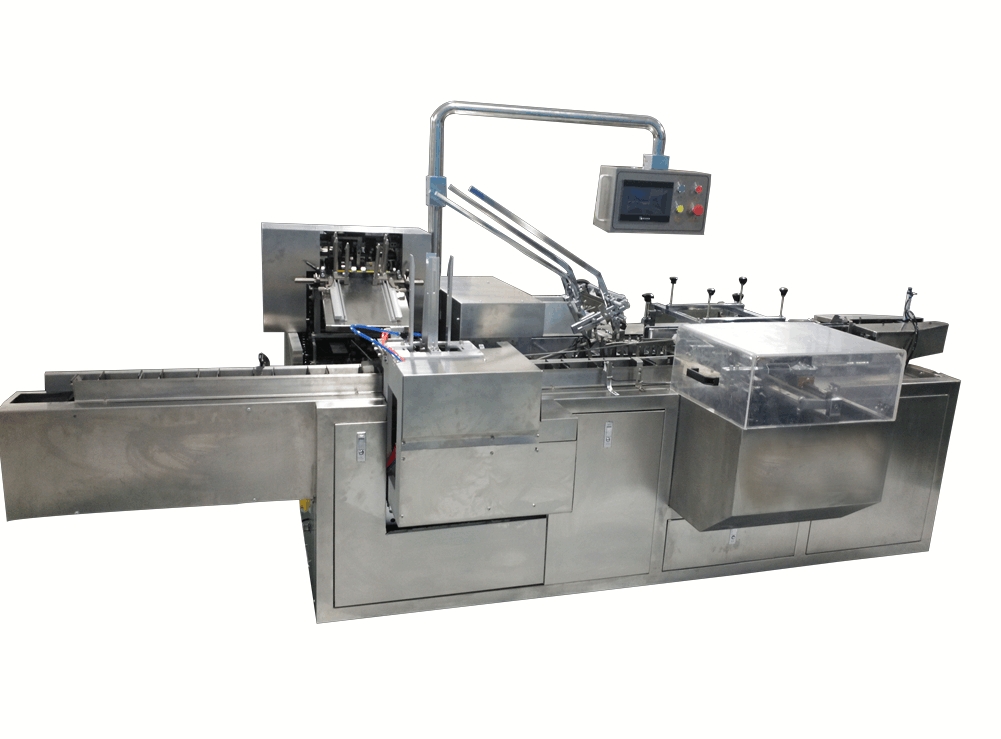

Automatic Hot Melt Glue Carton Packing Machine

Steel type wheel of automatic hot melt glue cartoning machine

Insert products into box by the hot melt glue cartoning machine

Starwheel of automatic hot melt glue cartoning machine

Samples packed by automatic hot melt glue cartoning machine2

$31600 $28500

The automatic hot melt glue carton packing machine is suitable for food, bottle, cosmetic, pouch, cartoning blister, injection, medicine, condom, tube, ointment, and wrapped products.

- General Details

Automatic Hot Melt Glue Carton Packing Machine

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: T/T, L/C

Introduction for Automatic hot melt glue carton packing machine

The automatic hot melt glue carton packing machine is suitable for food, bottle, cosmetic, pouch, cartoning blister, injection, medicine, condom, tube, ointment, and wrapped products. The machine finished running by a series of photo-electric controller to make the machine stability and guarantee the packing quality. It includes 1 to 4 folds leaflet automatic folding, cantons in suction and open, products and leaflet put into, printing batch number, sealing or option hot-glue device. The machine can be single used or linked with Filling Machine, Blister Packing Machine, Shrink Machine, Three-Dimensional Packaging Machine to form a production chain.

The features of Automatic hot melt glue carton packing machine

- International famous brand of electrical component such as PLC touch screen, frequency inverters, etc.

- Adopt human-machine operation system.

- Automatically displaying device for trouble, speed and finished products counting.

- Machine running without pressing if no products or incorrect position of products. And stopping automatically if incorrect position of product into carton after return or no cartons or out of leaflets continuous.

- No products not suction leaflet, no leaflet not suction carton.

- Automatic detection and rejection device for lacking blister goods and leaflets.

- Protecting automatically for overloading.

- Stable performance, operation is easy.

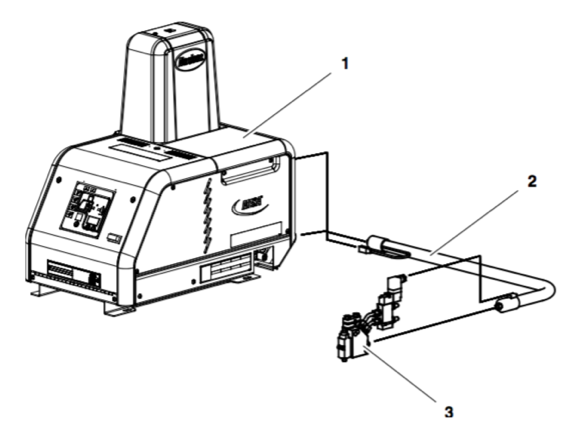

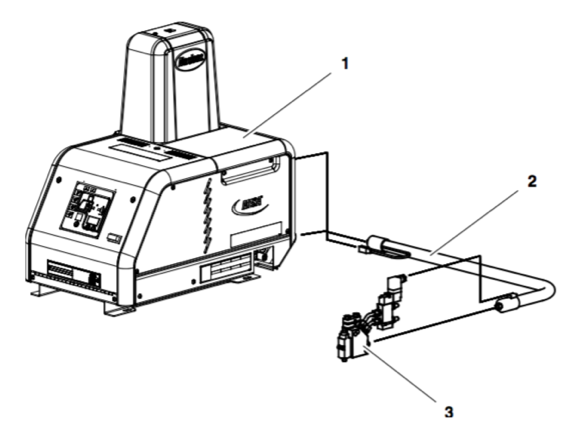

Main electric parts of the hot melt glue cartoning machine

Items Quantity Brand PLC 1 Mitsubishi(Japan) Human-machine interface 1 Weinview(Taiwan) Frequency converter 1 Delta(Taiwan) Circuit breaker 3P 1 Schneider(France) Circuit breaker 1P 1 Schneider(France) Contactor 1 Schneider(France) Intermediate relay 2 OMRON(Japan) Trunk module 4 OMRON(Japan) Switching Mode Power Supply 1 Mean Well(Taiwan) Photoelectric switch 4 OMRON(Japan) Approach switch 3 Locatran(Korea) Emergency stop button 1 Schneider(France) Power cut switch 1 Changjiang(China) Switch button 3 Schneider(France) Encoder 1 OMRON(Japan) Solenoid valve 4 AirTAC(Taiwan) Vacuum generator 2 BK(Taiwan) Pressure regulating valve 1 AirTAC(Taiwan) Motor 1 Omate(China) Straight rail 1 Hiwin(Taiwan) Bearing 1 Harbin(China) MESA Adhesive Melter 1 Nordson(USA) Description for the Nordson MESA adhesive melter

Nordson MESA adhesive melters are used in conjunction with Nordson hot melt hoses and applicators to create a hot melt application system.

The melter liquifies solid‐form hot melt and maintains the hot melt at the desired temperature. When the applicators are activated, the melter pumps the liquified hot melt through the hoses and out the applicator nozzles, where it is commonly applied to the surface of a product or package.System components

1) MESA melter

2) Hot melt hose

3) Hot melt Applicator

Model: Nordson MESA M6Intended Use

MESA melters are specifically designed to:

1) Melt and pump solid‐form hot melt materials that are engineered to be liquified and extruded at temperatures below 230°C (450 °F)

2) Be used with compatible hot melt hoses and applicators that are manufactured by Nordson Corporation

3) Be used in non‐explosive environmentsLimitations of Use

Use MESA melters only for the purpose for which they are designed. MESA melters should not be used

1) to melt or pump polyurethane reactive or polyamid hot melt materials or any other material that creates a health or safety hazard when heated

2) in environments that will require the melter to be cleaned using a water wash or sprayModes of Operation

MESA melters operate in the following modes:

1) Automatic scan—The melter automatically checks and displays the current temperature of the tank, hoses, and applicators to confirm that they are within their pre‐defined temperature range. By default, the melter is always in the automatic scan mode unless it is placed into another operating mode.

2) Standby—The temperatures of the tank, hoses, and applicators are reduced down from their operating temperature (hereafter referred to as set‐point temperature) by a pre‐set number of degrees.

3) Setup—The setup mode is used to configure melter control options and features and to review stored operating data. To prevent unauthorized changes to the melter’s configuration, the melter can be password‐protected

4) Fault—The melter alerts the operator when an abnormal event occurs.Specifications of the Nordson Melter

1) Weight of empty melter: 43.8 kg (96.5 lb)

2) Hose/gun capacity:4

3) Melt rate: 6.8 kg/h (15 lb/h)

4) Noise: 64dB (A) at maximum pump speed - Techical Info

The following is the standard model technical parameters, special requirements and features can be tailored.

Model No. SBM-PM120HMG Encasing speed 30-100 cartons/min Quality requirement of carton 300-350g/m2(gray cardboard), 250-350g/m2(ivory cardboard), Sample confirmation required(Corrugated paper) Dimension range of carton(L×W×H) (70-200) mm × (35-120) mm × (35-105) mm Motor power 1.5kw Power 220V/50Hz, Two-phase three wire Machine noise Less than 80dB Working pressure of compressed air 0.5-0.8 Mpa Air consumption 20m3/h Machine dimension(L×W×H) 3200mm×1400mm×1650mm Machine Weight 1200KG - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

- Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

- Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the traveling fee on your country) should be on your account and you need paid for the technician USD50 per day. Also you can go to our factory to do training.

- After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

- Comments