- Home

- Products

- Packing Machine

- Automatic horizontal tucking flap cartoning machine

Automatic horizontal tucking flap cartoning machine

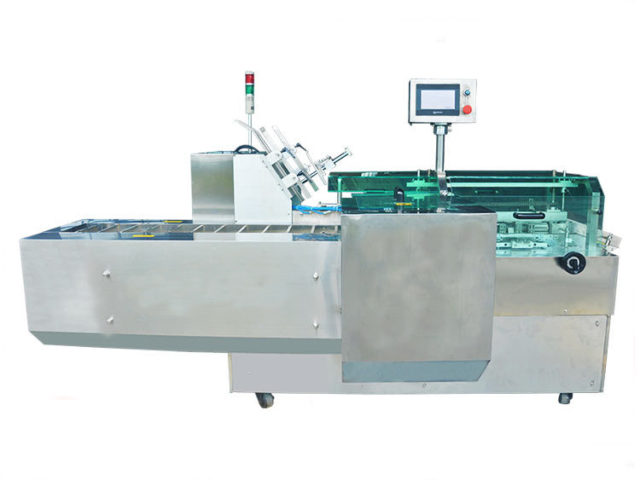

Automatic horizontal tucking flap cartooning machine SBM-CM30/80TC

Loading product system of intermittent motion cartoned Model SBM-CM30/80TC

$30888 $27800

Automatic horizontal tucking flap cartoning machine/cartoner Up to 80 cartons per minute

- General Details

Automatic horizontal tucking flap cartoning machine/cartoner

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: T/T, L/C

Overview

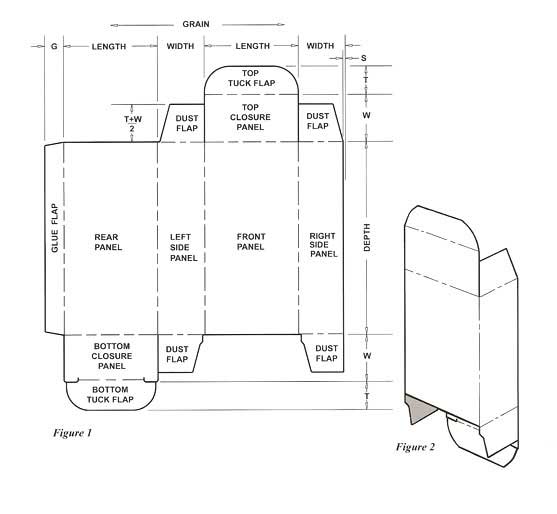

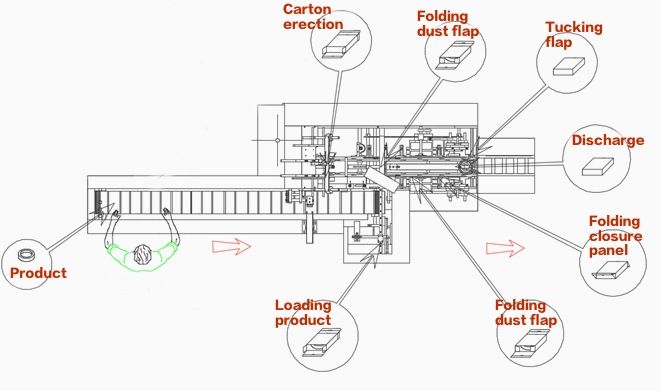

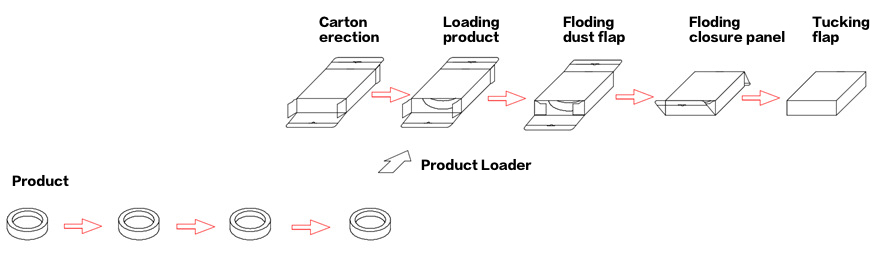

The model SBM-CM30/80TC is a rugged, mechanical, automatic horizontal cartoner for erecting, loading and closing end load cartons at speeds of up to 80 carton per minute. The cartoning machine is suitable for food, dairy, home good, cosmetic, hardware, electronic parts, pharmaceutical products and so on. It’s method of operation is:

- End load carton is removed from a supply magazine via vacuum system

- Carton is erected at a single product load station

- Product is automatically horizontally loaded into carton

- Loaded carton is transported to the closing position for tuck closure

- A completed carton is then automatically delivered from the machine to a convenient working height

Features

- International famous brand of electrical component such as PLC touch screen, frequency inverters, etc.

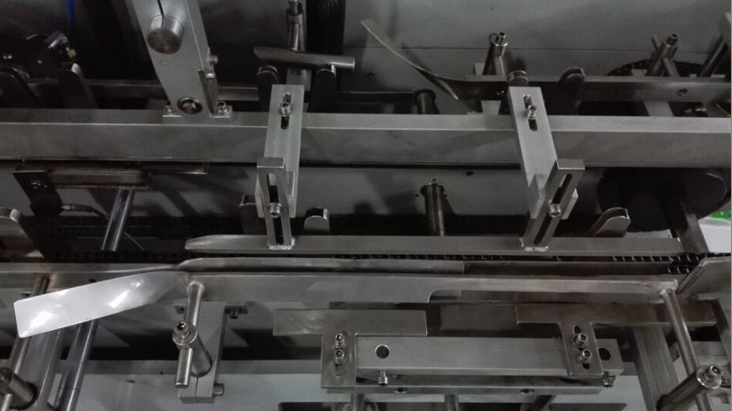

- Sanitary Construction (essentially stainless steel)

- Intermittent motion

- Up to 80 cartons per minute

- PLC Controls

- Adopt human-machine operation system.

- Automatically displaying device for trouble, speed and finished products counting.

- Machine running without pressing if no products or incorrect position of products. And stopping automatically if incorrect position of product into carton after return or no cartons or out of leaflets continuous.

- No products not suction leaflet, no leaflet not suction carton.

- Automatic detection and rejection device for lacking blister goods and leaflets.

- Protecting automatically for overloading.

- Stable performance, operation is easy.

Main components function

Color Touch Screen and PLC Control System

- Color touch screen man-machine interface, the parameters are clear and easy to set.

- Microcomputer control system, automatic alarm, shutdown function, production safety and efficiency.

- Automatic counting function, accurate control of production progress.

- After setting parameters, the machine can work by itself, saving labor and reducing cost.

Carton Magazine and carton forming system

The carton magazine is used for stacking paperboard cartons, and 300-500 paperboard cartons can be placed at one time. When used up, the paperboard cartons need to be added manually. The carton magazine can be adjusted according to the size of the paperboard carton.

End load carton is removed from the carton magazine via vacuum system.

Paperboard carton needs to be prefolded, and the indentation is generally 0.4mm deep.Infeed Conveyor System

The infeed conveyor system is made by stainless steel in accordance with the laws and regulations of food, pharmaceutical and other industries. It meets the requirements of GMP certification, and is widely used in the food and pharmaceutical industry. The conveyor belt can adjust the range of the product loader according to the size of the product. It is easy to adjust and easy to operate. Please note that the adjusted product loader can not be too large, in order that the product is in the right position. The product can be loaded manually, or loaded with robotic machine.Loading product system

Intelligent control system and high-precision sensor.

No product no loading carton.

No carton no loading product.

Automatic detection and control, alarm, shutdown protection.

Suggested that there are 2-3mm gaps between loaded product and carton in order to load product successfully.Folding flap system

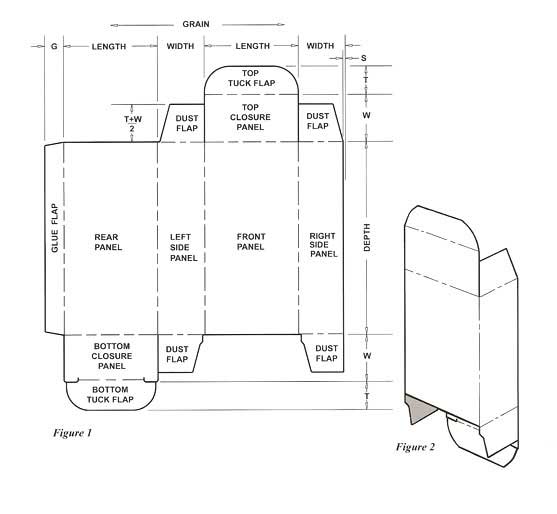

Folding flap system has folding dust flap, folding closure panel, tucking flap functions.

The rail system has automatic folding, folding, insert and other functions.

The system is compact, durable and easy to adjust and maintain. According to requirements, different specifications of the system can be selected for different specifications of cartons, and the corresponding folding flap system can be changed directly when changing products with different specifications, which is convenient and quick.Samples

- Techical Info

The following is the standard model technical parameters, special requirements and features can be customized.

Model No. SBM-CM30/80TC Speed 30-80 cartons/minute(depending on carton style and other factors) Carton thickness 250-450g/m2 Size range of carton(L×W×H) (120-300) mm × (110-170) mm × (20-100) mm Motor power 1.2kw Power supply 220v/50Hz Machine noise Less than 80dB Working pressure of compressed air 0.5-0.8 Mpa Air consumption 200-260L/min Machine dimension(L×W×H) 2700mm×1230mm×1700mm(depend on carton size) Machine Weight 1350kg - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

- Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO, THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

- Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the traveling fee on your country) should be on your account and you need paid for the technician USD50 per day. Also you can go to our factory to do training.

- After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

- Comments