- Home

- Products

- Labeling Machine

- Automatic horizontal labeling machine

Automatic horizontal labeling machine

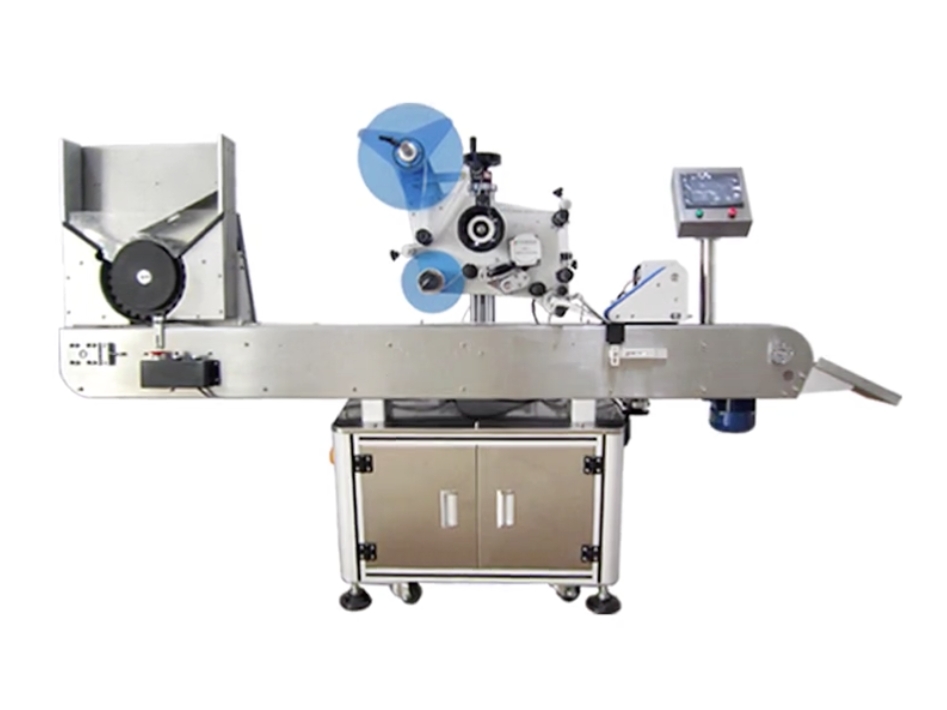

Automatic horizontal round bottle labeling machine model SBM-L21900

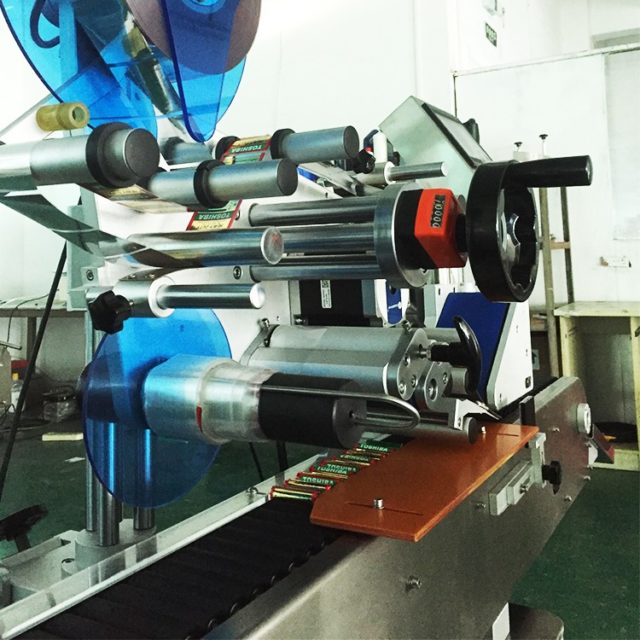

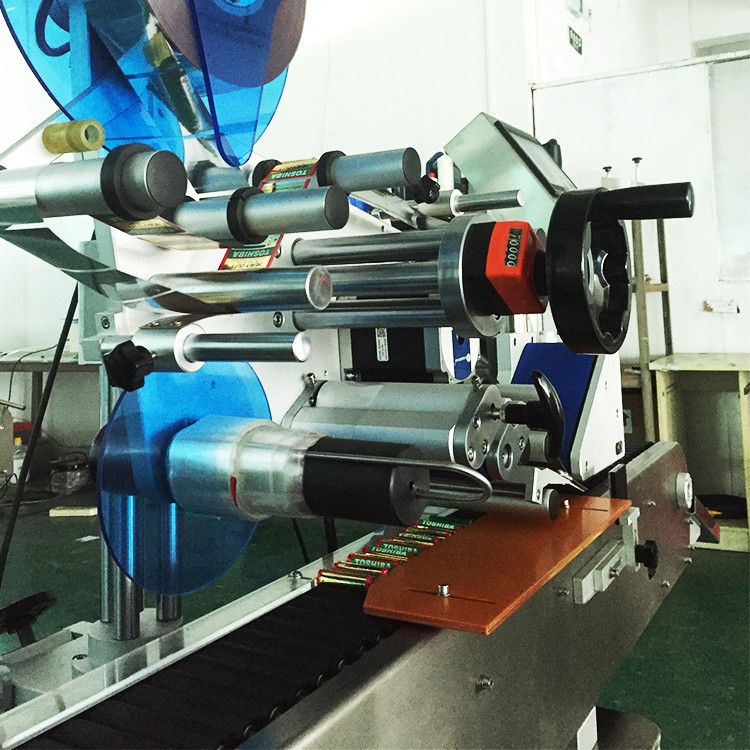

Side view of automatic horizontal round bottle labeling machne

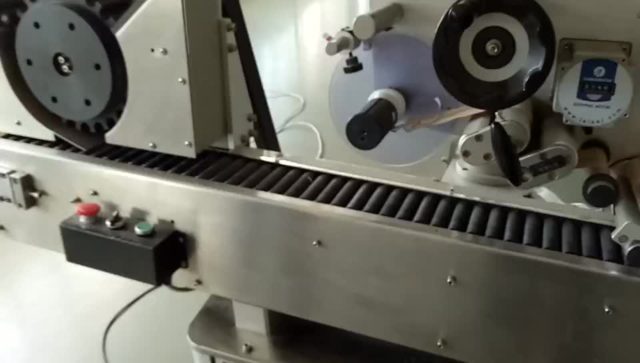

Infeed of the automatic horizontal labeling machine

$8835 $7950

Can be suitable for small round bottle which cann’t stand steadily, such as ampoule,tube, vial,pen and so on.

- General Details

Automatic Horizontal Labeling Machine Model SBM-L21900

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: T/T, L/C

Overview

Automatic horizontal labeling machine is suitable for small round bottle which cann’t stand steadily, horizontal transmission, horizontal labeling, can improve stability and label efficiency. Can select code printer or inkjet coder to labeling head to realize print product’s date, system number, inkjet bar code and other information. Can select code printer or inkjet coder to conveyor line to realize print product’s date, system number, inkjet bar code and other information. It is also suitable for assembly line.

Features

- High speed, adopt roller transmission sideling conveyor, bottles be putted on the right place automatically, labeling steadily, speed can catch to 400pcs/min. Saving large labor and material.

- High quality labeling, correct label belt be in right position, label cover label accurate, rolling and nobbing press label result in an even, no scrape, no air bubble on ever product. Improve packing quality.

- High stability,Panasonic PLC + KUNLUN TONGTAI Screen + Panasonic needle electronic eye + Leuze label testing electronic eye as the high grade electronic control, support equipment working at 7*24hours;

- Intelligent control, Automatic photoelectric tracing, no label for when product didn’t come, automatic correct, automatic testing, can avoid leaking and wasting.

- Techical Info

The following is the standard model technical parameters, special requirements and features can be customized.

Model SBM-L21900 Labeling Speed up to 300 bottles per minute Labeling Accuracy ±1mm Product Range diameterφ18mm~φ21mm,height25mm~100mm/td> Label Size (bottom)Width20~150mm,Length20~100mm Power supply AC220V/50Hz AC380V/50Hz Optional Workable Height 470-780mm Air Pressure 5-6kg/cm Dimension(L×W×H) 2020×650×1450mm Machine Weight Approx.200kg - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

- Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO, THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

- Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the traveling fee on your country) should be on your account and you need paid for the technician USD50 per day. Also you can go to our factory to do training.

- After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

- Comments