- Home

- Products

- Filling Machine

- 4 Heads Semi automatic Filling Machine for Perfume

4 Heads Semi automatic Filling Machine for Perfume

$4558 $4098

The vacuum filling machine for perfume is pure pneumatic equipment, without power. It's one of most economic filling machine, especially suitable for perfume, toilet water, and other small doses of filling agent products.

- General Details

4 Heads Semi-automatic Filling Machine for Perfume

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: L/C,T/T

The semi automatic filling machine for perfume is developed on the basis of overseas advanced technology. It’s ideal equipment for cosmetic factory filtrating cosmetic water and perfume water.

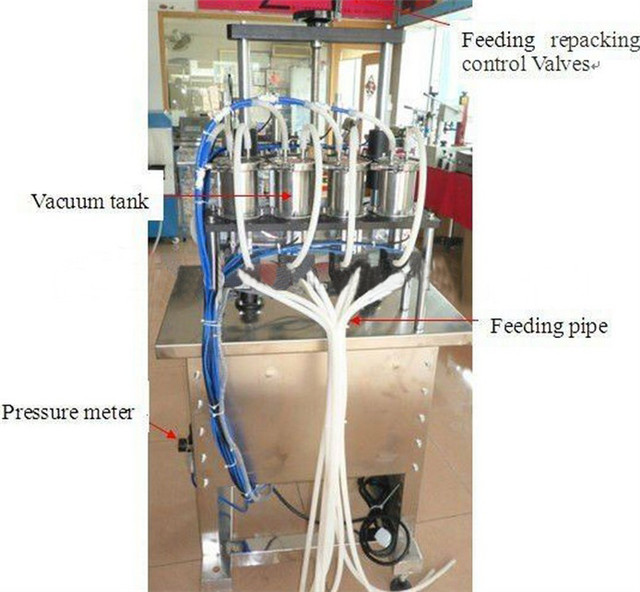

It adopts stainless steel 304-2B or 316L with pneumatic diaphragm pump as pressure source so as to positive pressure.The semi automatic filling machine for perfume is pure pneumatic equipment, without power. It’s one of most economic filling machine, especially suitable for perfume, toilet water, and other small doses of filling agent products. This is your ideal choice. The 4 heads filling machine sets by vacuum level filling principle. No matter the bottle volume is consistent, filling liquid surface will remain the same.

This series of machine is easy to operate, the operator just put the bottle in filling his head or card to pedal control can perform filling.Illustration of semi automatic vacuum filling machine with 4 heads

Details of 4 heads semi automatic filling machine for perfume

Work Principle for 4 heads semi automatic filling machine

- The work principle of this machine(discharge material by itself type) is: switch on the handle valve to connect the air source. Put the filling container right under the filling head, make use of the spring force of the baffle to make filling container upright and seal with filling head. At this time cam open mechanical valve, make the valve of vacuum bottle closed and the suction valve open, make the vacuum generator generate vacuum(negative pressure).

- vacuum system formed(vacuum bottle-filling head-filling container-silica gel tube of filling head).vacuum suction drive the materials filling into the container. the height of filling the materials in the container rise to the height of the external wrapped tube of the filling head. As the vacuum suction get through the external wrapped tube and suck up materials in the container into vacuum bottle and keep materials in the container a certain height all the time until the filling container removed. the vacuum generator stopped occurring vacuum as mechanical valve closed. suction tube closed. valve of the vacuum bottle opened, materials reflow into the barrel due to gravity, and one time cycle filling finished.

Function and Feature of the 4 heads semi automatic vacuum filling machine

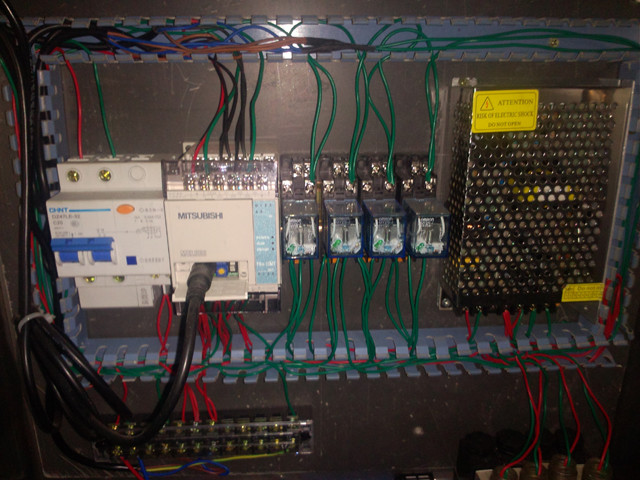

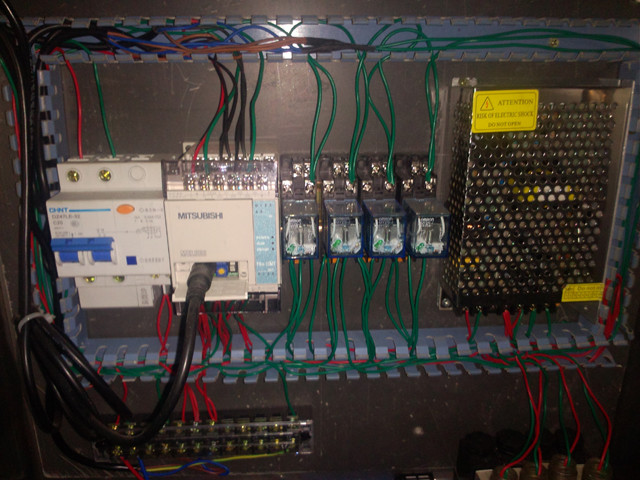

The machine adopts PLC automatic control program, Especially suitable for high bubble or irregular products filling. The design concept:by increasing pressure on the filling head, vacuum generator achieves a partial sealing environment in the reflow liquid bottle and filling container, thus generating a partial vacuum (negative pressure), and achieve filling process through vacuum suction.

An ideal machine that can reach the desired filling speed and effect after practical commissioning the machine according to size of the filling container.Sample bottles of the 4 heads semi automatic vacuum filling machine

Packaging in wooden case before ocean delivery for 4 heads semi automatic

- Techical Info

Model No. SBM-V04 Bottle height 250mm Bottle Mouth Maximum Diameter 20mm Minimum Diameter 4.5 mm Adjustable liquid High-Level (Away from the bottle) 26-50 mm Profile Dimensions (Excluding liquid storage bottle) L×W×H 660×470×1330mm Adaptable environment temperature (0-30) °C Power 3AC 380V (cas for your requirement) Vacuum pump XD-020(Explosion-proof type2X-4A) Pumping rate 5.5(Explosion-proof type 4) L/second Motor power 0.75kw - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

- Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

- Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account and you need paid for the technician USD50 per day. Also you can go to our factory to do training.

- After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

- Comments