- Home

- Products

- Sealing Machine

- Form fill seal machine

Form fill seal machine

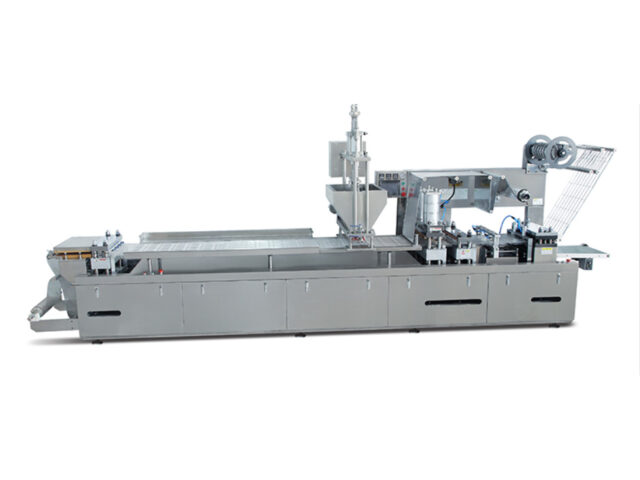

SBM-HFFS420L Plastic cup form fill seal machine

All kinds of products made by the form fill seal machine

Plastic cup forming filling sealing machine suits for food packaging such as milk, yogurt, chocolate, jam, fruit juice and condiment etc. It is also suitable for biscuit, candy, tablet and capsule.

- General Details

Form Fill Seal Machine, Plastic Cup Form Fill Seal Machine, Automatic Blister Packaging Machine

-

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: T/T, L/C

Introduction for form fill seal machine

Plastic cup form fill seal machine suits for food packaging such as milk, yogurt, chocolate, jam, fruit juice and condiment etc. It is also suitable for biscuit, candy, tablet and capsule.

The machine adopts PLC control interface, frequency control, simple operation.

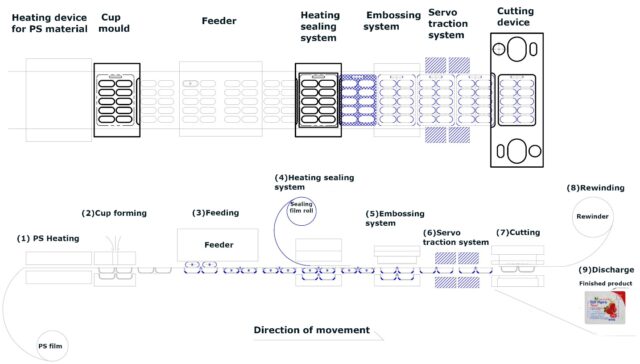

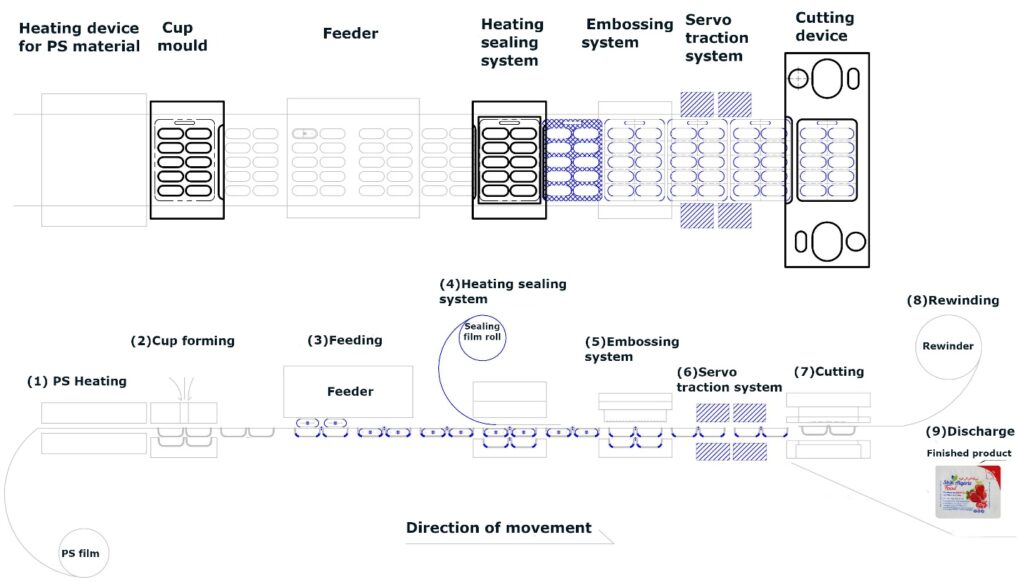

The work flow of form fill seal machine is :

Non-printed PVC/PS/PET Sheet Roll unwinding→Heating→Cup Blister Thermoforming One Color Chocolate Cream Filling→Plastic/Aluminum Foil Hot Sealing (Single PH Sensor for top printed sealing film) →Embossing (To make Batch Number optional) →Servo Traction (Sheet Feeding is controlled by servomotor) Cup Blister Cutting→Transport Final Product Out Automatically.

The form fill seal machine can also work in line with cartoning machine or pillow packing machine(optional).

Suitable for material: PVC, PS, PET.

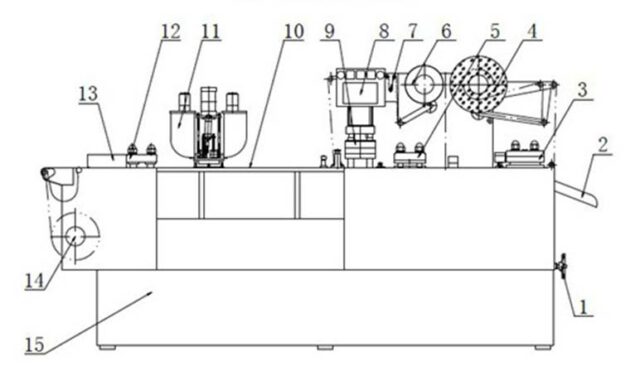

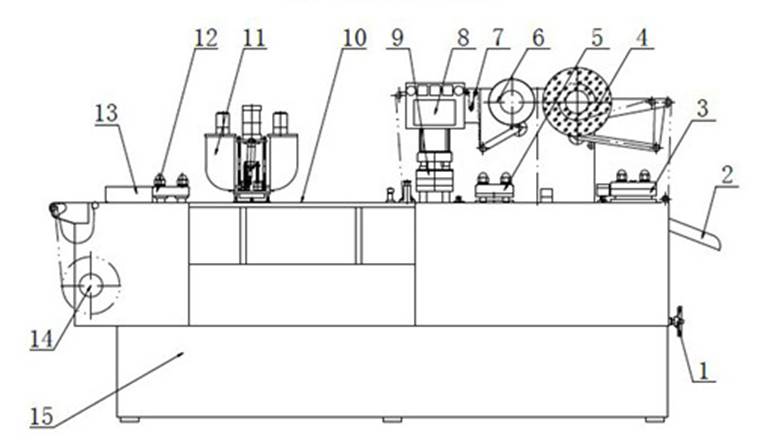

Outline drawing of the machine

1.Handle 5.Perforation mould 9.Heat-sealing station 13.Heating device 2.Ejecting mouth 6.Alu foil device 10.Working table 14.PS device 3.Punching station 7.Photocell 11.Feeder 15.Machine body 4.Waste material device 8.Human-machine interface 12.Forming station Work flow chart of form fill seal machine

Features of the form fill seal machine

1) Heating and Forming station.

The heating device is evenly heated, the size of cup is the same after forming, and the forming station adopts the structure of replaceable mold, which realizes the flexible operation of one machine with multiple uses.

2) Feeding system.

Materials such as powder or granule are loaded by dispenser. Liquid or cream are filled by self-developed material pump. Cream and liquid can be filled by the pump, and the filling accuracy can reach ± 5%. Enterprises do not need to replace the product line with multiple sets of pump body.

3) Heating and sealing device.

The heating and sealing device are driven by cylinder. High temperature sealing, evenly heated, firm bonding, no wrinkling.

4) PLC control

Forming pressure and the host pressure display function, the operation status is clear at a glance.

Heating and forming station, heat sealing, barrel insulation and heating using temperature control instrument, accurate temperature control.

PLC system expansion function is complete, simple operation, frequency conversion speed control, travel distance and other detailed parameters are controlled and displayed on the PLC. Meet the requirements of customers for a variety of complex packaging action settings.

With host voltage overload protection and reminding function.

5) Photoelectric sensor for positioning on top of the film.

Ensure the accuracy of sealing film and plastic cups when encapsulating and punching and cutting. Enhance the grade of the finished product.

6) Servo motor traction system

The traction system is driven by servo motor, just input the corresponding value in the PLC screen to complete the adjustment of the stroke, precise control of the feeding size, accurate to the silk unit.

According to the actual production needs of customers, we will provide two sets of traction solutions, roller traction and traction clamps, to choose from, flexible configuration to meet customer production needs.

7) Punching and recycling system

Punching output finished products, shearing neatly.

The equipment is equipped with recycling device to improve production efficiency.

8) Finished product output device

The output of finished products is fully automatic. The output device can also be changed to a conveyor belt structure according to the customer’s needs.

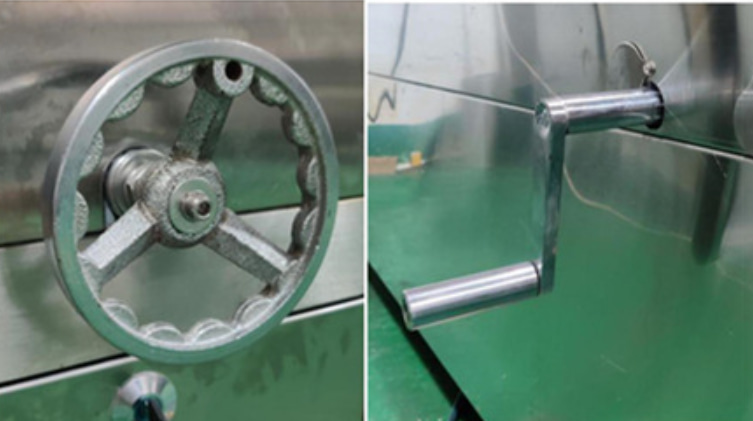

9) Workstation adjustment method

Adopt the lower fixing method to fix the work station seat, and adjust each work station movement with the hand crank wheel.

Samples made by the form fill seal machine

-

- Techical Info

The following is the standard model technical parameters, special requirements and features can be customized.

Model No. SBM-HFFSC320 SBM-HFFS420L Punching frequency 15-25 times/min 15-30 times/min Max. Forming area & Depth 160x320x24mm 420x180x25mm Max. Width of film sheet 320mm 420mm Electrical 380v, 50Hz, 3PH Dimension 4000X780X1750mm 4500X820X1800mm Weight 1800kg 3000kg Mould cooling Tap water or Recycling water Air Pressure 0.4-0.6Mpa Air Consumption 0.3m3/min Low Film Material PVC, PET, PS, PVDC Upper Sealing Film Aluminum foil, paper aluminum, composite film, dialysis paper - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

- Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO, THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

- Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the traveling fee on your country) should be on your account and you need paid for the technician USD150 per day. Also you can go to our factory to do training.

- After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

- Videos