Blister packaging machine, Blister machine for capsule, tablet, jelly, E-cig replacer

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: T/T, L/C

Introduction

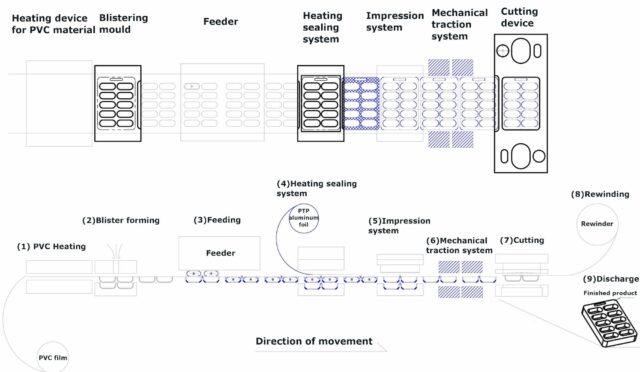

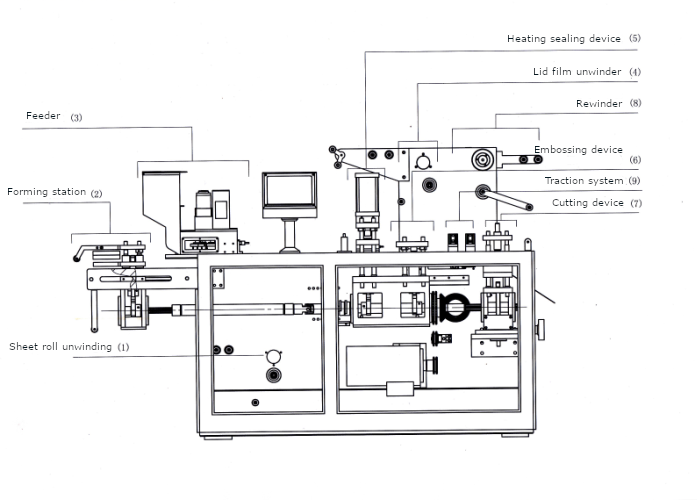

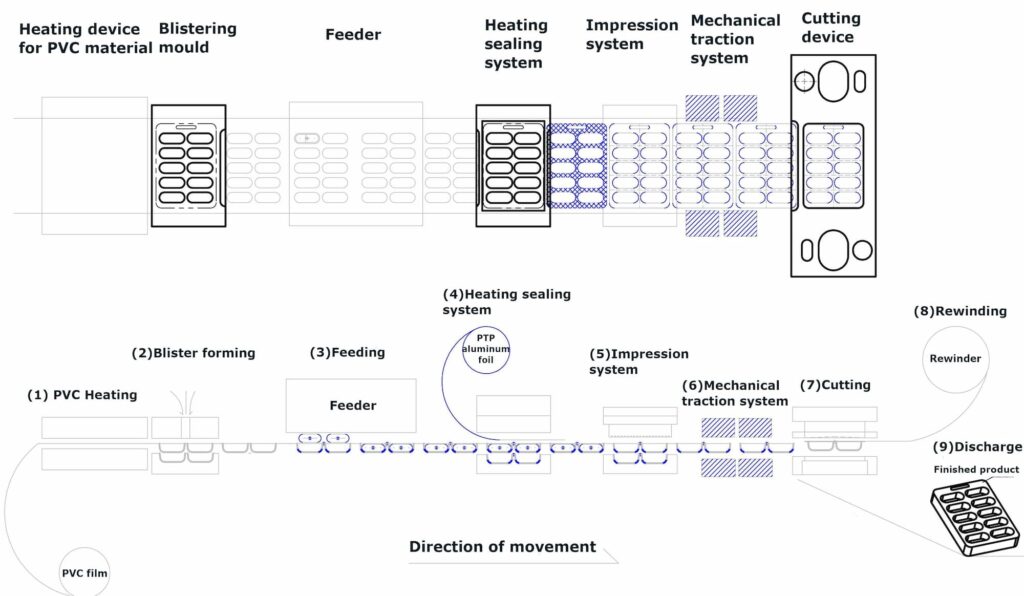

Blister packaging machine, with the functions of aluminum molding forming, filling and sealing packaging, has a high degree of automation and can reduce packaging costs. The machine occupies less space, multi-functional, high efficiency, low noise, no pollution to the working environment. It is the ideal equipment for food, pharmaceutical and cosmetic industries.