- Home

- Products

- Packing Machine

- Automatic VFFS packaging machine for liquid

Automatic VFFS packaging machine for liquid

$37800 $35800

The VFFS packaging machine is widely used in food, medicine and chemical industries as well as nonfood detergent, grease and other fluid, semi fluid automatic quantitative packaging.

- General Details

Automatic VFFS packaging machine for liquid

- Email: reylee@shinebenmach.com

- Cellphone: +86 135 8037 1935

- Port: Guangzhou/Shenzhen

- Payment Terms: T/T, L/C

Overview

The machine is widely used in food, medicine and chemical industries, such as curry sauce, bean paste, bean paste, lotus paste, fish and meat, fruit, wax gourd, fruit sauce, hot pot sauce, baked salad sauce, jam, peanut butter, tomato paste, transparent jelly, etc., as well as nonfood detergent, grease and other fluid, semi fluid automatic quantitative packaging.

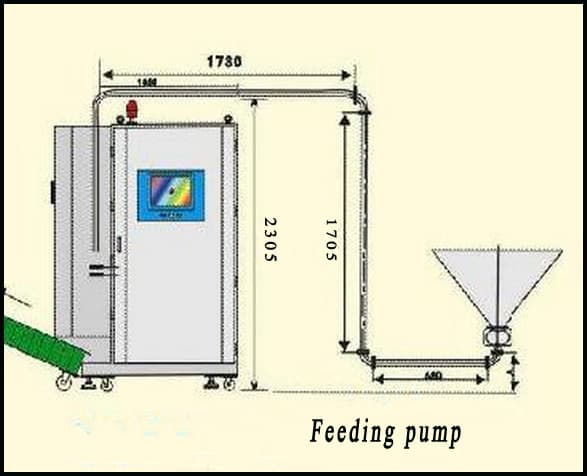

The packaging machine can pack materials ranging from 500g to 10kg. The length of the bag can be adjusted. When there are various product specifications and the width of the bag is not fixed, according to the packaging specifications and weight of the bag, multiple sets of molding machines with different packaging specifications can be purchased. With different material delivery pumps, the automatic quantitative filling packaging of objects under high temperature can be realized, which can effectively improve the production efficiency and avoid secondary pollution caused by bacterial invasion.Features for the VFFS packaging machine

- It has the functions of fluid and semi fluid transportation, bag forming, weight adjustment, vacuum sealing, cutting and counting.

- The overall appearance and molding parts are made of stainless steel, clean and hygienic, in line with the food hygiene standards.

- The computer operating system adopts color touch screen, digital humanized management, and is designed with many advanced functions such as automatic shutdown and timely alarm for material shortage and package shortage, which makes the operation easier and the maintenance more convenient.

- The control part adopts Mitsubishi PLC programming control, with stable and reliable performance and self-test prompt function.

- The imported 304 mirror pipe is used as the conveying pipeline, so the filling can be transported smoothly and stably. The pipeline connection adopts quick installation joint, which is convenient for cleaning.

- The advanced control program has been tested for a long time and its performance is stable. The maximum weight error of the package can be reduced to 0.6%, which is far lower than the weight error standard stipulated by the state.

- 304 stainless steel feed pump, strong and durable, high standard pressure, especially suitable for the transportation of high viscosity materials.

- The electrical components are made of international brand products with reliable quality and convenient replacement.

- The packaging capacity can reach more than 1.5 tons per hour, and the automatic filling and sealing can be completed above 85 degrees to avoid secondary pollution, improve work efficiency and reduce production cost.

Application and samples

Client visiting

Workshop

Exhibition

- Techical Info

The following is the standard model technical parameters, special requirements and features can be customized.

Model SBM-AVPM620 Packing Speed 12-15 bags/min (depending on the products and packing material) Filling range 300-2000g Bag size(L*W) 150-450*100-300mm Film width(WxL) 220-620mm Air consumption 0.65Mpa Gas consumption 0.5m3/min Motor power 8kw Power 380V/50Hz Packing material(L×W×H) PET/PE, PET/AL, FOIL/PE, PET/PE, NYLON/PE, etc. Dimension(L×W×H) Approx. 1450mm×1200mm×1850mm Machine Weight Approx.860kg - Order Enquiry

Start Order Now.Fill in any product details to make it as clear as possible for us to understand your requirements.

- Service

- Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO, THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

- Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine(The time of train depend on you worker). The expenses (air ticket ,food , hotel,the traveling fee on your country) should be on your account and you need paid for the technician USD150 per day. Also you can go to our factory to do training.

- After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).